Understanding the Revolutionary Properties of Carbon Kevlar Composites

In the world of advanced materials, carbon kevlar fabric stands as a pinnacle of engineering excellence, combining the incredible strength of carbon fiber with the remarkable durability of Kevlar. This hybrid material has revolutionized multiple industries, from aerospace to sporting goods, offering an unparalleled blend of lightweight construction and superior performance characteristics.

The unique properties of carbon kevlar fabric arise from the synergistic combination of two exceptional materials. Carbon fibers provide exceptional stiffness and strength-to-weight ratio, while Kevlar adds outstanding impact resistance and flexibility. Together, they create a composite material that overcomes the limitations of traditional materials while offering enhanced functionality across diverse applications.

Essential Characteristics of Carbon Kevlar Materials

Mechanical Properties and Performance Metrics

When evaluating carbon kevlar fabric for your project, understanding its mechanical properties is crucial. The material exhibits extraordinary tensile strength, typically ranging from 3,000 to 4,000 MPa, while maintaining a density significantly lower than steel or aluminum. This remarkable strength-to-weight ratio makes it ideal for applications where weight reduction is critical without compromising structural integrity.

The fabric's impact resistance is particularly noteworthy, with Kevlar fibers providing superior protection against dynamic loads and sudden impacts. This characteristic makes carbon kevlar fabric an excellent choice for protective equipment and high-stress applications where both strength and impact absorption are essential.

Weave Patterns and Material Configurations

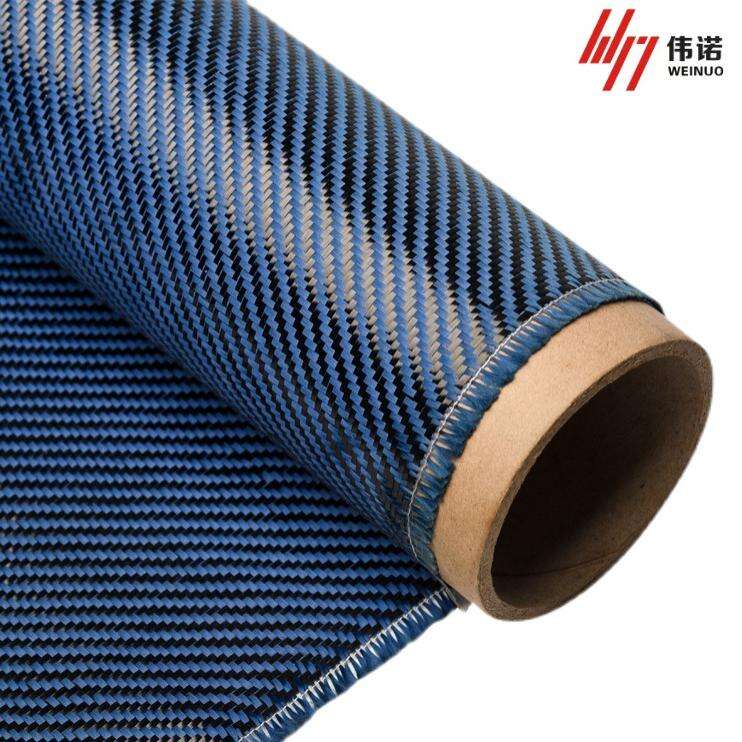

Carbon kevlar fabric comes in various weave patterns, each optimized for specific applications. The plain weave offers balanced properties in all directions, while twill weaves provide better draping capabilities and aesthetic appeal. Unidirectional configurations maximize strength in a particular direction, making them perfect for applications with known stress orientations.

The ratio of carbon to Kevlar fibers can be customized to meet specific performance requirements. Higher carbon content increases stiffness and strength, while greater Kevlar content enhances flexibility and impact resistance. Understanding these configurations is crucial for selecting the right fabric for your application.

Application-Specific Selection Criteria

Aerospace and Aviation Requirements

In aerospace applications, carbon kevlar fabric must meet stringent performance and safety standards. The material needs to demonstrate exceptional fatigue resistance, thermal stability, and resistance to environmental factors. Aerospace-grade fabrics typically feature precise fiber orientation and specialized resin systems to ensure optimal performance at high altitudes and extreme temperatures.

For aircraft components, the fabric's ability to maintain structural integrity under varying loads and environmental conditions is paramount. This includes resistance to UV radiation, moisture, and temperature fluctuations, all while providing the necessary strength and stiffness for aerodynamic efficiency.

Automotive and Transportation Applications

The automotive industry utilizes carbon kevlar fabric for components requiring high strength, low weight, and excellent impact resistance. Body panels, structural reinforcements, and safety components benefit from the material's ability to absorb energy during impacts while maintaining structural integrity.

When selecting fabric for automotive applications, considerations include crash performance, vibration damping, and long-term durability under repeated stress cycles. The material must also be compatible with automotive manufacturing processes and finishing requirements.

Processing and Manufacturing Considerations

Surface Treatment and Preparation

Proper surface preparation of carbon kevlar fabric is crucial for achieving optimal bonding with matrix materials. This includes cleaning, sizing application, and surface activation treatments to ensure strong interfacial adhesion. The choice of surface treatment depends on the intended application and the type of resin system being used.

Manufacturing processes must account for the fabric's unique handling characteristics. Unlike pure carbon fiber, carbon kevlar fabric may require specialized cutting tools and handling procedures to prevent fiber fraying and ensure clean edges.

Resin Compatibility and Curing Parameters

The selection of compatible resin systems is critical for maximizing the performance of carbon kevlar fabric. Epoxy resins are commonly used due to their excellent adhesion properties and mechanical performance. However, the specific resin formulation must be carefully chosen based on processing requirements and end-use conditions.

Curing parameters, including temperature, pressure, and time, must be optimized to achieve proper fiber wet-out and void-free lamination. These parameters vary depending on the fabric architecture and resin system, requiring careful attention during process development.

Cost-Benefit Analysis and Material Selection

Long-term Performance Considerations

When evaluating carbon kevlar fabric options, consider the total lifecycle cost rather than just initial material expenses. The superior durability and performance characteristics often result in reduced maintenance requirements and extended service life, offsetting higher upfront costs.

Environmental exposure, chemical resistance, and fatigue performance should be carefully assessed based on the intended application. This includes consideration of UV stability, moisture absorption, and resistance to various chemical environments.

Economic Factors and Supply Chain Management

Material availability, lead times, and minimum order quantities can significantly impact project timelines and costs. Establishing relationships with reliable suppliers and understanding market dynamics helps ensure consistent material quality and timely delivery.

Consider the processing costs associated with different fabric styles and configurations. Some materials may offer lower raw material costs but require more expensive processing equipment or longer manufacturing cycles.

Frequently Asked Questions

What makes carbon kevlar fabric different from pure carbon fiber or pure Kevlar?

Carbon kevlar fabric combines the high stiffness and strength of carbon fiber with the superior impact resistance and flexibility of Kevlar. This hybrid material offers better overall performance characteristics than either material alone, particularly in applications requiring both strength and impact protection.

How should carbon kevlar fabric be stored and handled?

Store carbon kevlar fabric in a clean, dry environment away from direct sunlight and extreme temperatures. Handle the material with care using clean gloves to prevent contamination. Proper storage and handling practices help maintain the material's properties and ensure optimal performance in the final application.

What are the key factors in determining the right weave pattern?

The choice of weave pattern depends on several factors, including the required mechanical properties, draping characteristics, and aesthetic considerations. Plain weaves offer balanced properties, while twill weaves provide better conformability to complex shapes. Unidirectional patterns maximize strength in specific directions based on loading requirements.

How does temperature affect carbon kevlar fabric performance?

Temperature can significantly impact the performance of carbon kevlar fabric. While carbon fibers maintain their properties at high temperatures, Kevlar fibers may experience some property degradation above certain temperature thresholds. Consider the operating temperature range when selecting materials and designing composite structures.