Understanding the Critical Role of Prepreg Materials in Advanced Composites

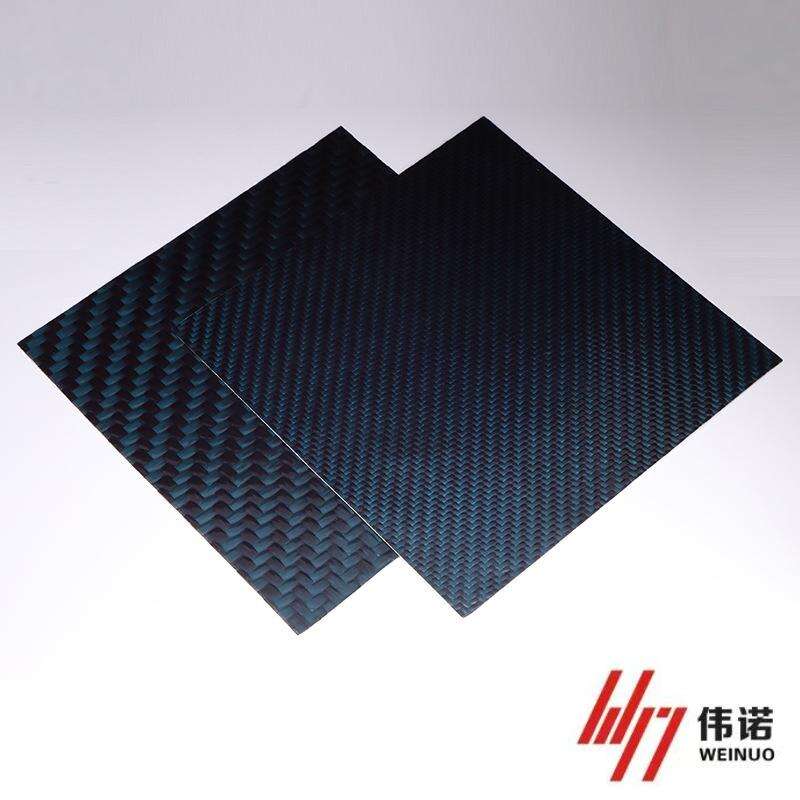

The selection of carbon fiber prepreg materials stands as one of the most crucial decisions in advanced composite manufacturing. These sophisticated materials, consisting of carbon fiber reinforcements pre-impregnated with a thermosetting resin system, have revolutionized industries from aerospace to sporting goods. Their unique combination of high strength, low weight, and processing advantages makes them indispensable in modern engineering applications.

The complexity of carbon fiber prepreg selection extends far beyond basic mechanical properties. Engineers and manufacturers must carefully evaluate multiple factors to ensure their chosen material will deliver optimal performance in the final application while remaining cost-effective and manufacturable. This comprehensive guide explores the essential considerations that should drive your selection process.

Mechanical Performance Requirements

Strength and Stiffness Characteristics

When evaluating carbon fiber prepreg materials, the fundamental mechanical properties deserve primary attention. The fiber type and architecture significantly influence the strength and stiffness of the final composite. High-modulus fibers offer superior stiffness but may sacrifice impact resistance, while intermediate-modulus options provide a more balanced performance profile.

The resin system also plays a vital role in determining mechanical properties. Different epoxy formulations offer varying levels of toughness, environmental resistance, and processing characteristics. Advanced resin systems may incorporate toughening agents or modifiers to enhance specific performance attributes while maintaining overall structural integrity.

Temperature and Environmental Resistance

Operating environment considerations must guide your carbon fiber prepreg selection. High-temperature applications require specialized resin systems with elevated glass transition temperatures (Tg). Aerospace components, for instance, may need to withstand extreme temperature variations while maintaining structural integrity.

Environmental factors such as moisture exposure, chemical resistance, and UV stability should also influence material selection. Some prepreg systems offer enhanced resistance to specific environmental conditions through modified resin chemistries or protective additives.

Processing and Manufacturing Considerations

Cure Cycle Requirements

The cure cycle characteristics of carbon fiber prepreg materials significantly impact manufacturing efficiency and cost. Traditional aerospace-grade materials often require high-temperature, high-pressure autoclave curing, while newer formulations may offer out-of-autoclave (OOA) processing options. Understanding your available processing equipment and production volume requirements helps narrow down suitable material choices.

Cure temperature and time requirements affect both production throughput and energy costs. Some advanced prepreg systems offer rapid cure cycles or lower temperature curing options, potentially reducing manufacturing expenses while maintaining performance standards.

Handling and Layup Characteristics

The practical aspects of working with carbon fiber prepreg materials deserve careful consideration. Tack level, drape properties, and out-time characteristics influence layup efficiency and part quality. Materials with balanced tack properties facilitate easier handling while ensuring adequate fiber placement accuracy.

Storage requirements and shelf life also affect material management and inventory costs. Most prepreg materials require frozen storage to prevent premature curing, and their out-time limitations must align with your production scheduling capabilities.

Cost and Supply Chain Factors

Material Cost Analysis

The cost analysis of carbon fiber prepreg materials must extend beyond simple per-pound pricing. Consider the total cost of ownership, including storage requirements, processing expenses, and yield factors. Higher-priced materials might prove more economical when accounting for improved processing characteristics or reduced scrap rates.

Volume requirements and minimum order quantities can significantly impact material costs. Establishing strong supplier relationships and understanding their production capabilities helps ensure consistent material availability at competitive prices.

Supply Chain Reliability

Supply chain considerations have become increasingly critical in prepreg material selection. Evaluate supplier manufacturing capacity, quality consistency, and delivery reliability. Multiple source qualification may be necessary for critical applications to ensure uninterrupted production capability.

Regional availability and import/export regulations can affect material accessibility and cost. Understanding these logistics challenges helps in developing robust supply chain strategies that support your production requirements.

Quality and Certification Requirements

Material Qualification Standards

Industry-specific qualification requirements often dictate material selection options. Aerospace applications typically demand materials meeting stringent certification standards, while other industries may have more flexible requirements. Understanding and documenting these requirements early in the selection process prevents costly requalification efforts.

Quality control measures and testing requirements vary significantly between different carbon fiber prepreg materials. Establish clear specifications and acceptance criteria aligned with your application requirements and industry standards.

Documentation and Traceability

The importance of material traceability and documentation cannot be overstated. Maintain comprehensive records of material certifications, batch testing results, and processing parameters. This documentation supports quality assurance programs and may be essential for regulatory compliance.

Regular supplier audits and material qualification updates help ensure consistent quality and performance. Implement robust material management systems to track inventory, shelf life, and usage history.

Frequently Asked Questions

How long can carbon fiber prepreg materials be stored?

Carbon fiber prepreg materials typically require frozen storage at approximately -18°C (0°F) to maximize shelf life. Under these conditions, most materials remain viable for 6-12 months, though specific storage requirements and shelf life vary by manufacturer and material type. Regular monitoring of storage conditions and careful tracking of material age are essential for quality control.

What determines the out-time limitations of prepreg materials?

Out-time limitations are primarily influenced by the resin system's chemistry and the storage temperature. Factors such as humidity, temperature, and exposure to light can affect how long the material remains workable outside frozen storage. Most prepregs have specific out-time limits ranging from several days to several weeks at room temperature.

Can different prepreg materials be used together in the same component?

While it's technically possible to combine different prepreg materials in a single component, careful consideration must be given to compatibility factors including cure cycles, thermal expansion coefficients, and mechanical property transitions. Any mixed-material design should undergo thorough testing and validation to ensure structural integrity and performance requirements are met.