The Revolutionary Impact of Carbon Fiber Prepreg Materials in Modern Industries

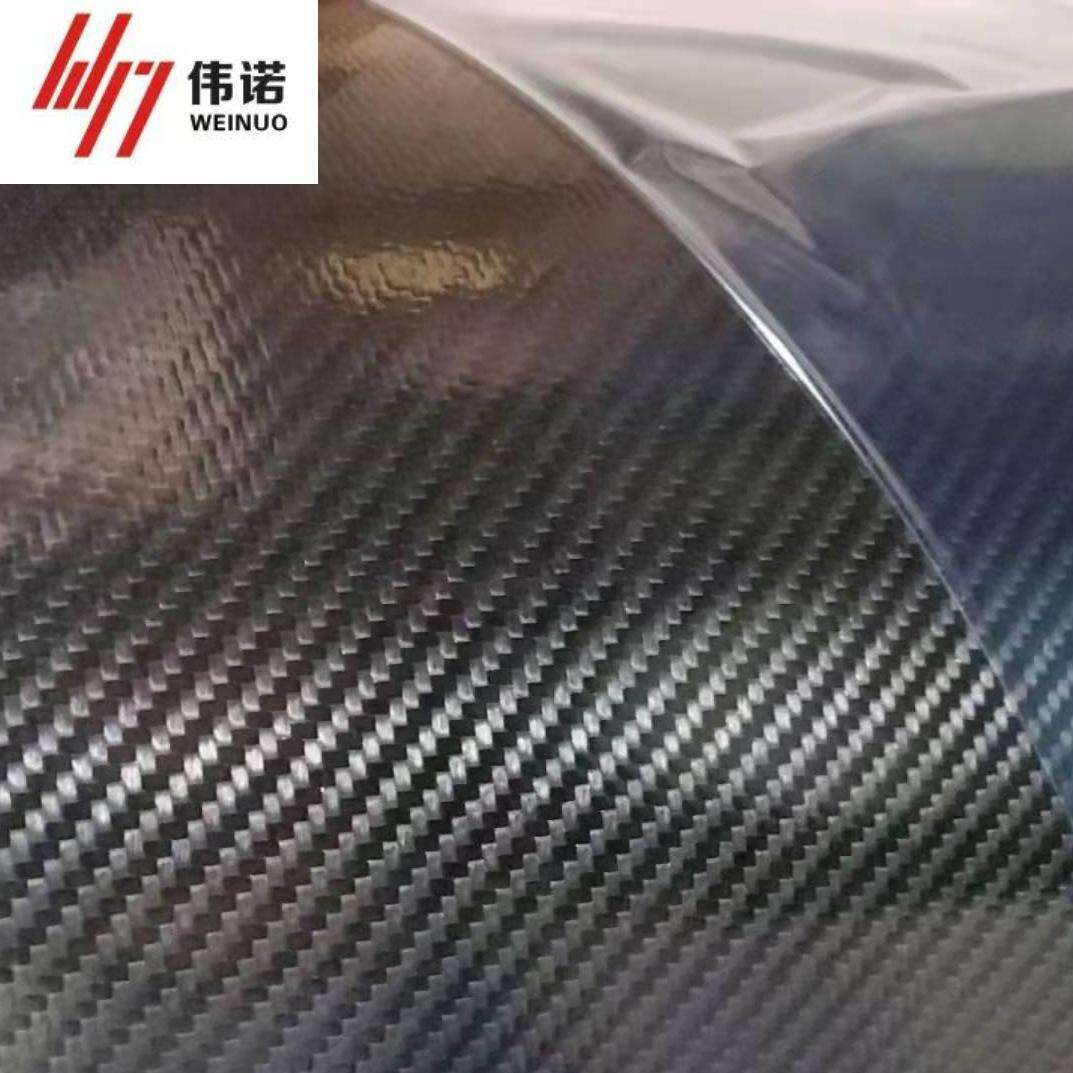

Carbon fiber prepreg has emerged as a game-changing material in advanced manufacturing, particularly transforming the aerospace and automotive industries. This advanced composite material, consisting of carbon fiber reinforcements pre-impregnated with a thermoset resin system, offers an unprecedented combination of strength, lightness, and versatility. As industries strive for greater efficiency and performance, carbon fiber prepreg continues to push the boundaries of what's possible in modern engineering and design.

The evolution of carbon fiber prepreg technology has revolutionized how manufacturers approach component design and production. With its exceptional strength-to-weight ratio and superior mechanical properties, this material has become indispensable for creating high-performance parts that meet increasingly demanding industry standards.

Aerospace Applications of Carbon Fiber Prepreg

Primary Aircraft Structures

In modern aircraft construction, carbon fiber prepreg plays a crucial role in manufacturing primary structures. Wing components, fuselage sections, and tail assemblies increasingly rely on this advanced material. The aerospace industry values carbon fiber prepreg for its ability to reduce aircraft weight while maintaining or improving structural integrity. This weight reduction directly translates to improved fuel efficiency and increased payload capacity.

Modern commercial aircraft like the Boeing 787 Dreamliner and Airbus A350 XWB extensively utilize carbon fiber prepreg in their construction, with composites comprising up to 50% of their structural weight. These applications demonstrate the material's capability to withstand extreme conditions while providing superior performance characteristics.

Interior Components and Systems

Beyond structural applications, carbon fiber prepreg finds extensive use in aircraft interior components. Floor panels, overhead storage bins, and seating structures benefit from the material's lightweight properties and design flexibility. These interior applications contribute to overall weight reduction while maintaining the stringent safety and durability requirements of aerospace standards.

The material's excellent fire-resistant properties and ability to meet strict aerospace safety regulations make it particularly valuable for cabin interior applications. Additionally, its superior surface finish capabilities enable manufacturers to create aesthetically pleasing components without sacrificing performance.

Automotive Industry Implementation

Performance Vehicle Components

The automotive sector has embraced carbon fiber prepreg particularly in high-performance and luxury vehicles. Body panels, chassis components, and structural elements made from carbon fiber prepreg offer significant weight reduction while enhancing vehicle performance. Racing teams and premium automotive manufacturers regularly employ this material to achieve optimal power-to-weight ratios and improved handling characteristics.

From Formula 1 race cars to premium sports vehicles, carbon fiber prepreg components have become synonymous with high-performance automotive engineering. The material's ability to be molded into complex shapes while maintaining structural integrity makes it ideal for creating aerodynamic body panels and structural reinforcements.

Mass Market Applications

As manufacturing processes become more efficient and cost-effective, carbon fiber prepreg is gradually finding its way into mainstream automotive production. Electric vehicle manufacturers, in particular, are leveraging this material to extend range through weight reduction. Body panels, battery enclosures, and structural components manufactured from carbon fiber prepreg help offset the weight of heavy battery systems.

The automotive industry's push toward electrification has accelerated the adoption of carbon fiber prepreg materials. Manufacturers are developing innovative applications that balance performance requirements with production scalability, making these advanced materials more accessible to broader market segments.

Manufacturing and Processing Considerations

Quality Control and Storage

Working with carbon fiber prepreg requires precise control over manufacturing conditions. Temperature, humidity, and storage conditions significantly impact material performance. Manufacturers must maintain strict environmental controls and follow specific handling procedures to ensure optimal results. The material typically requires refrigerated storage to prevent premature curing and maintain its processing characteristics.

Quality assurance processes involve regular testing of material properties, monitoring of storage conditions, and careful tracking of material life cycles. These controls ensure that the final products meet the exacting standards required by aerospace and automotive applications.

Processing Techniques

Advanced processing methods for carbon fiber prepreg include autoclave curing, out-of-autoclave processing, and automated fiber placement. Each technique requires specialized equipment and expertise to achieve optimal results. The choice of processing method depends on factors such as component size, production volume, and performance requirements.

Manufacturers continue to innovate in processing techniques, developing more efficient and cost-effective methods for working with carbon fiber prepreg. These advancements are crucial for expanding the material's applications across different industry sectors.

Future Trends and Developments

Technological Advancements

The future of carbon fiber prepreg technology shows promising developments in several areas. Researchers are working on new resin systems that offer improved processing characteristics and mechanical properties. Additionally, advances in automation and digital manufacturing are making production more efficient and consistent.

Emerging technologies like artificial intelligence and machine learning are being integrated into manufacturing processes, optimizing production parameters and improving quality control. These developments are expected to drive further adoption of carbon fiber prepreg across various industries.

Sustainability Initiatives

Environmental considerations are becoming increasingly important in material development and manufacturing processes. The industry is focusing on developing more sustainable production methods and recycling technologies for carbon fiber prepreg materials. Manufacturers are exploring bio-based resins and improved recycling processes to reduce environmental impact.

These sustainability efforts are likely to play a crucial role in the future growth and adoption of carbon fiber prepreg technology, particularly as industries face increasing pressure to reduce their environmental footprint.

Frequently Asked Questions

What makes carbon fiber prepreg superior to traditional materials?

Carbon fiber prepreg offers an exceptional combination of high strength, low weight, and excellent fatigue resistance. Unlike traditional materials, it provides consistent fiber-to-resin ratios and superior mechanical properties, making it ideal for demanding aerospace and automotive applications.

How long can carbon fiber prepreg be stored?

When properly stored under refrigerated conditions (typically around -18°C), carbon fiber prepreg can maintain its properties for 6-12 months. However, specific storage life varies depending on the resin system and manufacturer specifications.

What are the main challenges in working with carbon fiber prepreg?

The primary challenges include the need for controlled storage conditions, precise processing parameters, and specialized equipment for curing. Additionally, material costs and the requirement for skilled technicians can impact implementation in mass production scenarios.