Understanding the Revolutionary World of Advanced Composite Materials

Industrial-grade carbon fiber fabric represents one of the most significant advancements in modern manufacturing and engineering materials. This remarkable composite material has transformed numerous industries, from aerospace and automotive to construction and renewable energy. With its exceptional strength-to-weight ratio and versatile applications, industrial-grade carbon fiber fabric continues to push the boundaries of what's possible in material science.

As the demand for lighter, stronger, and more durable materials grows, manufacturers and engineers increasingly turn to industrial-grade carbon fiber fabric for their most challenging projects. This sophisticated material offers unprecedented performance characteristics that make it indispensable in high-stakes applications where failure is not an option.

Core Properties and Characteristics

Mechanical Strength and Durability

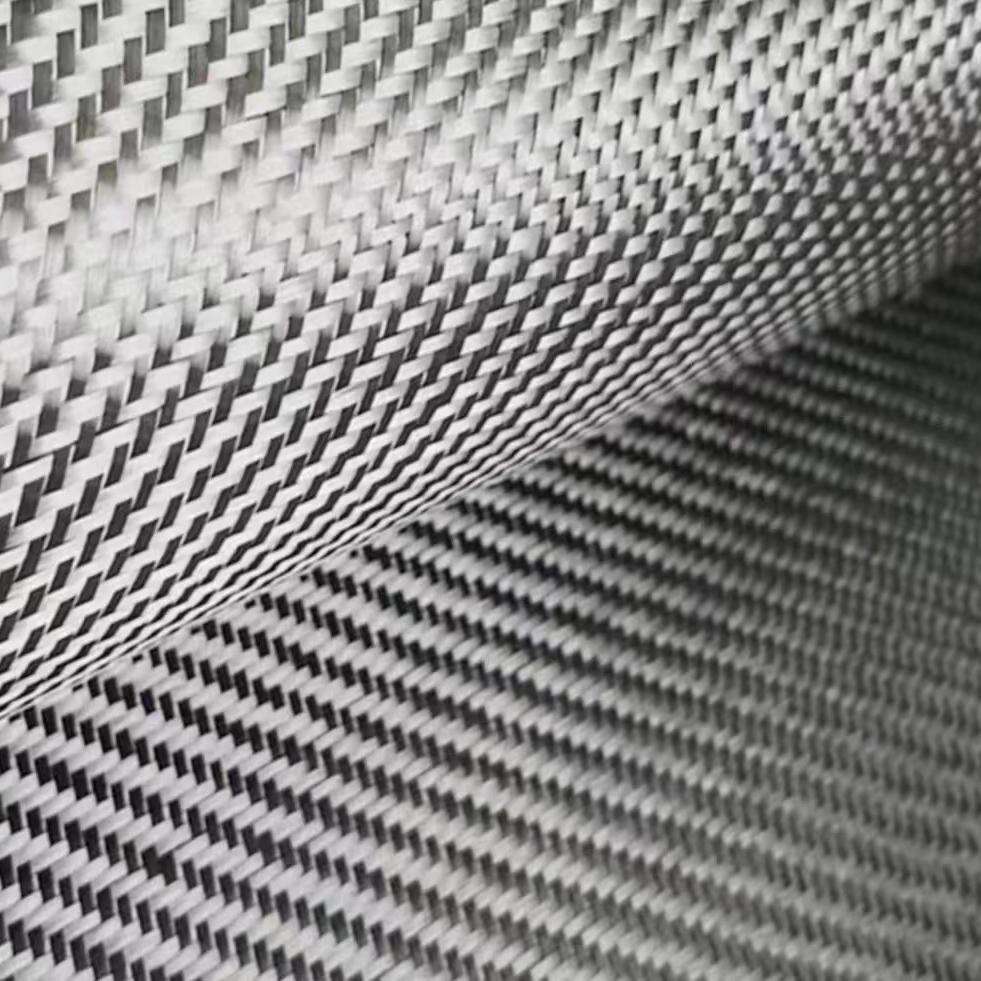

Industrial-grade carbon fiber fabric exhibits extraordinary tensile strength, often exceeding that of steel while weighing considerably less. The material's unique molecular structure, consisting of tightly interwoven carbon atoms, creates an incredibly robust lattice that can withstand extreme forces and environmental conditions. This exceptional durability makes it particularly valuable in applications requiring long-term reliability under harsh conditions.

The material's fatigue resistance is equally impressive, showing minimal degradation even after repeated stress cycles. This property makes industrial-grade carbon fiber fabric an ideal choice for components subject to continuous vibration or cyclical loading patterns.

Weight and Density Advantages

One of the most compelling features of industrial-grade carbon fiber fabric is its remarkably low density compared to traditional materials. This lightweight characteristic doesn't compromise its strength, resulting in a material that offers superior performance while reducing overall system weight. In transportation applications, this translates to improved fuel efficiency and enhanced vehicle performance.

The material's low mass also simplifies installation and handling procedures, reducing labor costs and minimizing workplace safety concerns associated with managing heavy materials.

Manufacturing Processes and Quality Control

Production Techniques

The manufacturing of industrial-grade carbon fiber fabric involves sophisticated processes that demand precise control and expertise. The journey begins with polyacrylonitrile (PAN) precursor fibers, which undergo careful oxidation and carbonization at extremely high temperatures. This process aligns the carbon atoms into powerful crystalline arrangements that give the material its extraordinary properties.

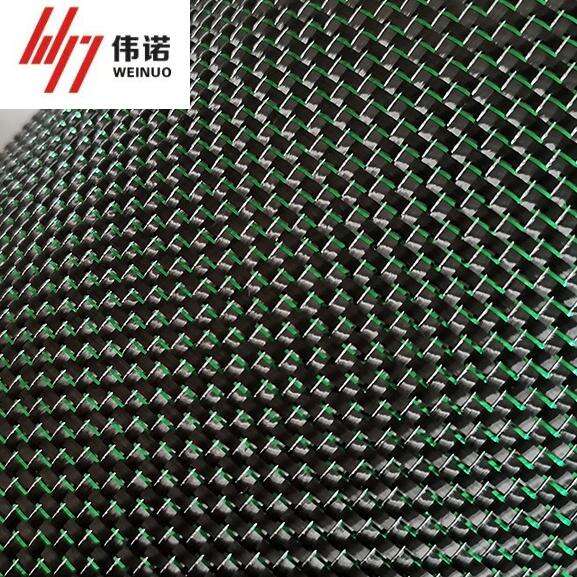

Advanced weaving techniques then transform these carbon fibers into fabric forms, with various weave patterns available to suit different applications. The choice of weave pattern significantly influences the final material properties, allowing manufacturers to tailor the fabric to specific performance requirements.

Quality Assurance Standards

Rigorous quality control measures ensure that industrial-grade carbon fiber fabric meets or exceeds industry specifications. Each production batch undergoes extensive testing for tensile strength, modulus, and uniformity. These tests verify the material's compliance with aerospace, automotive, or other relevant industry standards.

Manufacturers employ advanced inspection techniques, including ultrasonic scanning and microscopic analysis, to detect any potential defects or irregularities in the fabric structure. This comprehensive quality assurance process guarantees consistent performance and reliability.

Applications and Industry Uses

Aerospace and Defense

The aerospace industry represents one of the largest consumers of industrial-grade carbon fiber fabric, utilizing the material in aircraft components, spacecraft structures, and satellite systems. The material's high strength-to-weight ratio enables the construction of lighter aircraft that maintain exceptional structural integrity while consuming less fuel.

Defense applications leverage the material's impact resistance and durability for protective equipment, vehicle armor, and specialized military hardware. The ability to absorb and dissipate energy makes industrial-grade carbon fiber fabric particularly valuable in ballistic protection systems.

Automotive and Transportation

Modern automotive manufacturers increasingly incorporate industrial-grade carbon fiber fabric into vehicle designs to enhance performance and efficiency. From structural components to body panels, the material enables the creation of lighter vehicles without compromising safety or durability. This weight reduction directly contributes to improved fuel economy and reduced emissions.

High-performance racing vehicles particularly benefit from the material's properties, using it extensively in chassis components, aerodynamic elements, and safety systems. The material's ability to maintain structural integrity under extreme conditions makes it invaluable in competitive motorsports.

Cost Considerations and ROI

Initial Investment Analysis

While industrial-grade carbon fiber fabric typically requires a higher initial investment compared to traditional materials, the long-term benefits often justify the cost. The material's durability and minimal maintenance requirements contribute to reduced lifecycle costs, making it an economically viable choice for many applications.

Buyers should consider the complete cost picture, including installation, maintenance, and replacement expenses, when evaluating the material's financial impact. The extended service life and performance advantages frequently result in substantial long-term savings.

Performance Benefits and Value

The superior performance characteristics of industrial-grade carbon fiber fabric often translate into significant operational benefits. Reduced weight leads to lower energy consumption, while enhanced durability minimizes maintenance and replacement costs. These advantages can provide substantial returns on investment, particularly in high-performance applications.

Additionally, the material's resistance to corrosion and environmental degradation eliminates many traditional maintenance requirements, further improving its long-term value proposition.

Frequently Asked Questions

How does weather affect industrial-grade carbon fiber fabric?

Industrial-grade carbon fiber fabric demonstrates excellent resistance to environmental factors, including UV radiation, temperature extremes, and moisture. The material maintains its structural integrity and performance characteristics across a wide range of weather conditions, making it suitable for outdoor applications. However, proper coating and protection systems may be recommended for specific environmental exposures.

What maintenance does industrial-grade carbon fiber fabric require?

The material typically requires minimal maintenance compared to traditional materials. Regular visual inspections for damage or wear are recommended, but the inherent durability and corrosion resistance of industrial-grade carbon fiber fabric eliminate many conventional maintenance needs. When maintenance is necessary, it should be performed by qualified technicians following manufacturer specifications.

How long does industrial-grade carbon fiber fabric last?

When properly specified and installed, industrial-grade carbon fiber fabric can maintain its performance characteristics for decades. The actual service life depends on application conditions and environmental exposure, but many installations exceed 20-30 years with minimal degradation. This longevity contributes significantly to the material's overall value proposition and return on investment.