The Revolutionary Impact of Advanced Composites in Modern Engineering

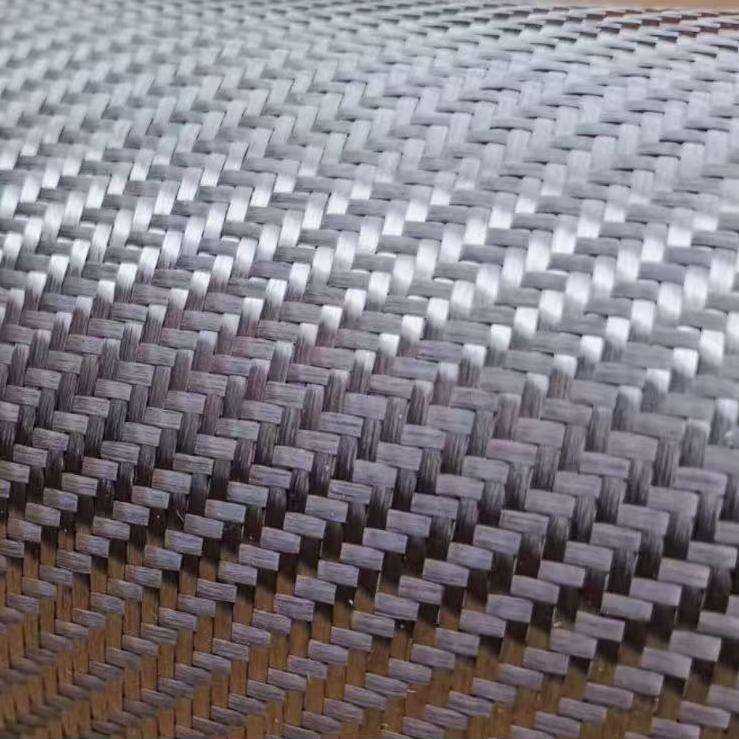

In the realm of high-performance materials, carbon fiber fabric has emerged as a game-changing innovation that continues to reshape the aerospace and automotive industries. This remarkable material combines exceptional strength with incredibly low weight, making it an invaluable resource for manufacturers who demand the utmost in performance and reliability. The unique properties of carbon fiber fabric have earned it an unshakeable position in the most demanding applications, from commercial aircraft to Formula 1 racing cars.

The aerospace and automotive sectors have embraced carbon fiber fabric as their material of choice due to its remarkable strength-to-weight ratio, which significantly outperforms traditional materials like steel and aluminum. This advanced composite material has become synonymous with innovation, enabling engineers to push the boundaries of design while maintaining the highest safety standards.

Engineering Excellence Through Advanced Material Science

Unprecedented Strength and Durability

The molecular structure of carbon fiber fabric creates a material that exhibits extraordinary tensile strength while remaining incredibly lightweight. When compared to steel, carbon fiber fabric can be up to five times stronger while weighing about one-fourth as much. This remarkable combination of properties makes it an ideal choice for critical components in both aircraft and high-performance vehicles.

Engineers have discovered that carbon fiber fabric's durability extends beyond mere strength. The material shows exceptional resistance to fatigue, meaning it can withstand repeated stress cycles without degradation. This characteristic is particularly valuable in aerospace applications, where components must maintain their integrity through thousands of pressurization cycles and varying atmospheric conditions.

Weight Reduction and Fuel Efficiency

The lightweight nature of carbon fiber fabric has revolutionized vehicle design across both industries. In aerospace, reducing aircraft weight directly translates to improved fuel efficiency and increased payload capacity. Commercial airlines have reported significant fuel savings after incorporating carbon fiber fabric components into their fleet, with modern aircraft like the Boeing 787 Dreamliner using the material for up to 50% of its structure.

In automotive applications, the weight reduction achieved through carbon fiber fabric usage has enabled manufacturers to create vehicles with enhanced performance characteristics while meeting increasingly stringent fuel efficiency standards. Sports car manufacturers have been particularly aggressive in adopting this technology, using carbon fiber fabric for everything from body panels to chassis components.

Manufacturing Innovation and Process Development

Advanced Production Techniques

The manufacturing processes for carbon fiber fabric have evolved significantly over the past decades. Modern production methods combine automated precision with carefully controlled environmental conditions to ensure consistent quality. The latest automated fiber placement technologies allow manufacturers to create complex shapes and structures that would be impossible with traditional materials.

Quality control in carbon fiber fabric production has reached unprecedented levels of sophistication. Manufacturers employ advanced testing methods, including ultrasonic inspection and computer tomography, to verify the structural integrity of components. This rigorous attention to detail ensures that every piece meets the exacting standards required for aerospace and automotive applications.

Cost-Effective Solutions and Scaling Production

While historically expensive, technological advances in carbon fiber fabric manufacturing have led to more cost-effective production methods. Automated processes and improved raw material synthesis have helped reduce costs while maintaining quality. This has made the material increasingly accessible to a broader range of applications in both industries.

The automotive industry, in particular, has benefited from these developments, with mass-market manufacturers now incorporating carbon fiber fabric components into their vehicles. This trend is expected to accelerate as production costs continue to decrease and environmental regulations drive demand for lighter, more efficient vehicles.

Environmental Impact and Sustainability Considerations

Lifecycle Analysis and Benefits

The environmental impact of carbon fiber fabric extends beyond its immediate application. While production requires significant energy input, the material's lightweight properties result in substantial fuel savings over the lifetime of a vehicle or aircraft. Studies have shown that the reduction in fuel consumption can offset the initial carbon footprint of production many times over.

Additionally, carbon fiber fabric components typically have a longer service life than their metal counterparts, reducing the need for replacement and minimizing waste. The aerospace industry has reported significant reductions in maintenance requirements for aircraft utilizing carbon fiber fabric structures, further contributing to their environmental benefits.

Recycling and Future Developments

Research into carbon fiber fabric recycling has made significant progress, with new technologies emerging to recover and repurpose the material. This advancement addresses one of the few remaining environmental concerns about carbon fiber fabric usage and promises to make the material even more sustainable in the future.

Innovation continues in the development of more environmentally friendly production methods and recycling techniques. These efforts are crucial as both industries strive to meet increasingly stringent environmental regulations while maintaining the performance advantages that carbon fiber fabric provides.

Frequently Asked Questions

What makes carbon fiber fabric superior to traditional materials?

Carbon fiber fabric offers an exceptional strength-to-weight ratio, superior fatigue resistance, and excellent durability compared to traditional materials like steel and aluminum. These properties make it ideal for applications where weight reduction is crucial while maintaining structural integrity.

How does carbon fiber fabric contribute to fuel efficiency?

The lightweight nature of carbon fiber fabric significantly reduces the overall weight of vehicles and aircraft. This weight reduction directly translates to improved fuel efficiency, lower emissions, and increased payload capacity in aerospace applications.

Is carbon fiber fabric environmentally sustainable?

While carbon fiber fabric production requires significant energy, its long-term environmental benefits through reduced fuel consumption and extended service life often outweigh the initial impact. Additionally, emerging recycling technologies are making the material increasingly sustainable.