Understanding the Revolutionary Impact of Advanced Composite Materials

In the realm of industrial engineering and manufacturing, carbon fiber cloth has emerged as a transformative material that's reshaping how we approach mechanical performance. This advanced composite material combines exceptional strength with remarkably low weight, making it an invaluable asset across numerous industrial applications. The unique properties of carbon fiber cloth have revolutionized everything from aerospace components to automotive structures, offering unprecedented improvements in mechanical efficiency and durability.

The Fundamental Properties of Carbon Fiber Cloth

Chemical Structure and Material Composition

Carbon fiber cloth consists of intricately woven strands of carbon fiber, each containing thousands of carbon filaments that are thinner than human hair. These filaments are created through a complex process called pyrolysis, where organic polymers like polyacrylonitrile undergo controlled heating and oxidation. The resulting material exhibits a unique crystalline structure that aligns carbon atoms in a pattern that maximizes strength while minimizing weight.

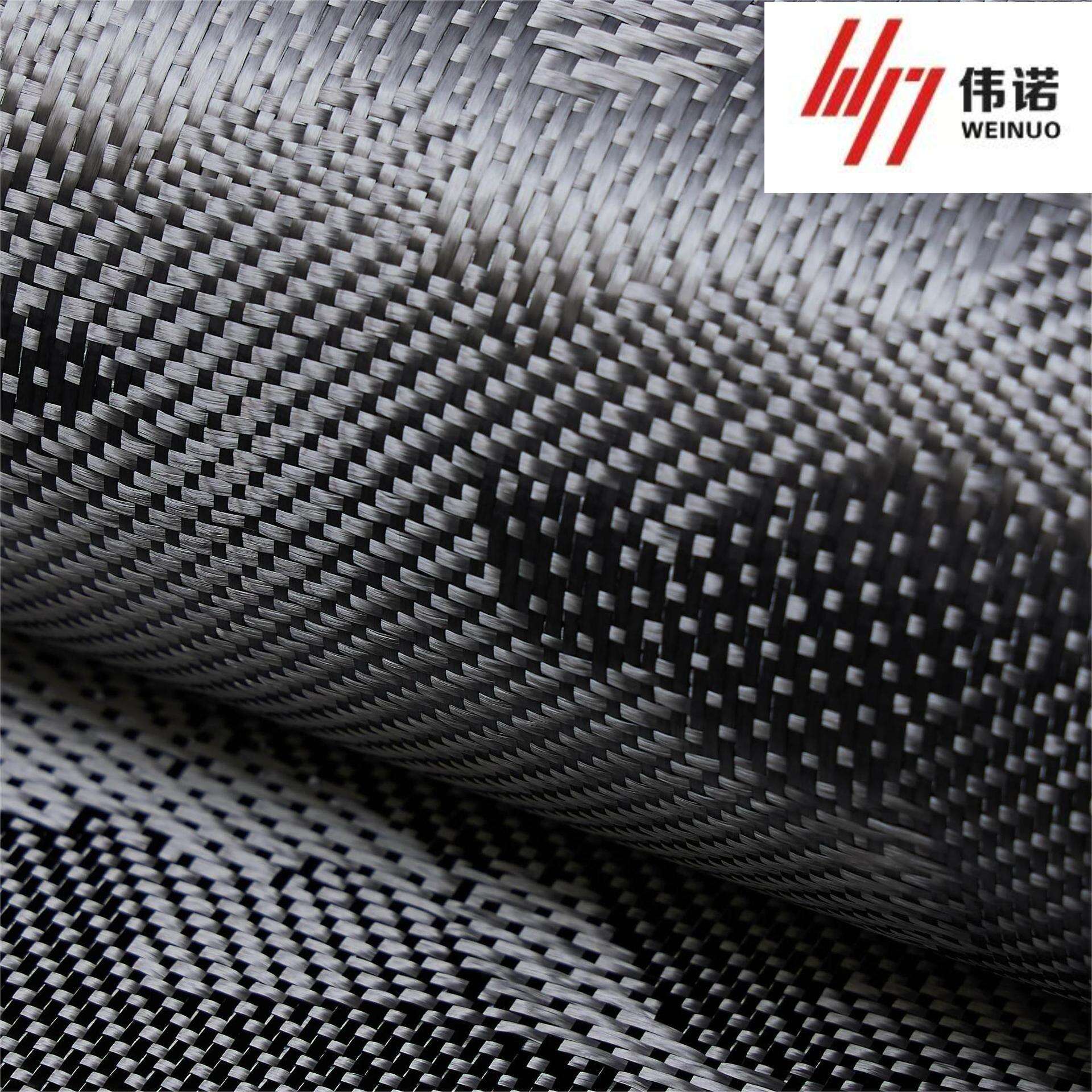

The weaving patterns used in carbon fiber cloth production play a crucial role in determining its final properties. Different weave styles, such as plain weave, twill weave, or satin weave, create varying degrees of strength, flexibility, and surface finish. This versatility in weaving patterns allows manufacturers to tailor carbon fiber cloth properties to specific application requirements.

Mechanical Characteristics and Performance Metrics

The mechanical properties of carbon fiber cloth are truly remarkable. With a strength-to-weight ratio that far exceeds traditional materials like steel or aluminum, it delivers exceptional tensile strength while maintaining minimal mass. This material typically exhibits tensile strengths ranging from 3,000 to 7,000 MPa, while its density remains around 1.6 g/cm³ – significantly lower than steel's 7.8 g/cm³.

Moreover, carbon fiber cloth demonstrates outstanding fatigue resistance and minimal thermal expansion, making it ideal for applications requiring dimensional stability under varying temperature conditions. These properties, combined with its natural vibration damping capabilities, create a material that excels in dynamic mechanical environments.

Industrial Applications and Performance Enhancement

Aerospace and Aviation Implementations

The aerospace industry has been at the forefront of carbon fiber cloth adoption. Modern aircraft utilize this material extensively in their structural components, from fuselage panels to wing structures. By incorporating carbon fiber cloth, manufacturers have achieved significant weight reductions while maintaining or even improving structural integrity. This translates directly into improved fuel efficiency and enhanced flight performance.

In spacecraft and satellite construction, carbon fiber cloth plays an equally crucial role. The material's ability to maintain stability under extreme temperature variations and its exceptional strength-to-weight ratio make it indispensable for space applications where every gram matters and structural reliability is paramount.

Automotive Engineering Advancements

The automotive sector has embraced carbon fiber cloth to enhance vehicle performance and efficiency. High-performance cars utilize this material in chassis components, body panels, and structural reinforcements. The reduced weight directly contributes to improved acceleration, better fuel economy, and enhanced handling characteristics.

Racing teams particularly benefit from carbon fiber cloth applications, where every weight reduction translates into competitive advantage. The material's ability to absorb impact energy while maintaining structural integrity also makes it valuable in safety applications, such as crash structures and protective components.

Manufacturing Processes and Integration

Production Techniques and Quality Control

Manufacturing with carbon fiber cloth requires precise control and specialized techniques. The material typically undergoes a resin infusion process, where epoxy or other polymer matrices are introduced to create a composite structure. Advanced manufacturing methods like autoclave curing ensure optimal fiber-to-resin ratios and eliminate voids or defects that could compromise performance.

Quality control in carbon fiber cloth production involves sophisticated testing methods, including ultrasonic inspection, x-ray analysis, and mechanical testing. These procedures ensure consistency in material properties and identify any potential structural anomalies before final application.

Integration Challenges and Solutions

While carbon fiber cloth offers exceptional benefits, its integration into existing manufacturing processes presents unique challenges. The material requires specialized handling techniques and specific tools for cutting, shaping, and joining. Advanced computer-aided design and manufacturing systems help optimize material usage and ensure precise component fabrication.

Engineers have developed innovative solutions for joining carbon fiber cloth components with traditional materials, including specialized adhesives and mechanical fastening systems. These developments have expanded the material's applicability across diverse industrial sectors.

Future Developments and Industry Trends

Emerging Technologies and Innovations

The future of carbon fiber cloth technology looks promising with ongoing research into enhanced manufacturing processes and material properties. Scientists are exploring nanotechnology applications to further improve strength and conductivity characteristics. New weaving techniques and hybrid materials are being developed to create even more versatile composite solutions.

Automation and artificial intelligence are revolutionizing carbon fiber cloth production, leading to more efficient manufacturing processes and reduced costs. These advancements are making the material more accessible to a broader range of industrial applications.

Sustainability and Environmental Considerations

As industry focus shifts toward sustainability, researchers are developing eco-friendly alternatives for carbon fiber cloth production. New recycling methods are emerging to recover and reuse carbon fibers, reducing environmental impact. Manufacturers are also exploring bio-based precursor materials to create more sustainable production processes.

The long-term durability and lightweight properties of carbon fiber cloth contribute to reduced energy consumption throughout product lifecycles, aligning with global sustainability goals.

Frequently Asked Questions

What makes carbon fiber cloth superior to traditional materials?

Carbon fiber cloth offers an exceptional combination of high strength, low weight, and durability that surpasses traditional materials like steel and aluminum. Its superior strength-to-weight ratio, corrosion resistance, and thermal stability make it ideal for demanding industrial applications.

How long does carbon fiber cloth typically last in industrial applications?

When properly manufactured and maintained, carbon fiber cloth components can last for decades. The material shows minimal fatigue and degradation under normal operating conditions, often outlasting traditional materials in similar applications.

Is carbon fiber cloth cost-effective for industrial use?

While initial costs may be higher than traditional materials, carbon fiber cloth often proves cost-effective over its lifecycle due to reduced maintenance requirements, longer service life, and operational benefits such as improved energy efficiency and reduced wear on related components.