The Revolutionary Impact of Advanced Composite Manufacturing

In the world of high-performance manufacturing, materials and processes that deliver exceptional results are constantly evolving. Among these innovations, prepreg carbon fiber has emerged as a game-changing technology that's reshaping industries from aerospace to automotive manufacturing. This advanced composite material represents a significant leap forward from traditional wet layup methods, offering unprecedented control, consistency, and performance characteristics that make it the preferred choice for demanding applications.

The evolution of composite manufacturing has led to increasingly sophisticated solutions, with prepreg carbon fiber standing at the forefront of this technological advancement. As industries push the boundaries of what's possible in terms of strength, weight reduction, and precision manufacturing, the advantages of prepreg systems become even more apparent.

The Science Behind Prepreg Carbon Fiber Systems

Chemical Composition and Material Structure

Prepreg carbon fiber consists of carefully engineered layers of carbon fiber reinforcement that have been pre-impregnated with a precisely measured amount of resin system. This resin is partially cured to a B-stage, creating a material that remains stable at room temperature while retaining the ability to flow and cure when exposed to heat and pressure. The molecular structure of the resin system is specifically designed to achieve optimal cross-linking during the final cure cycle.

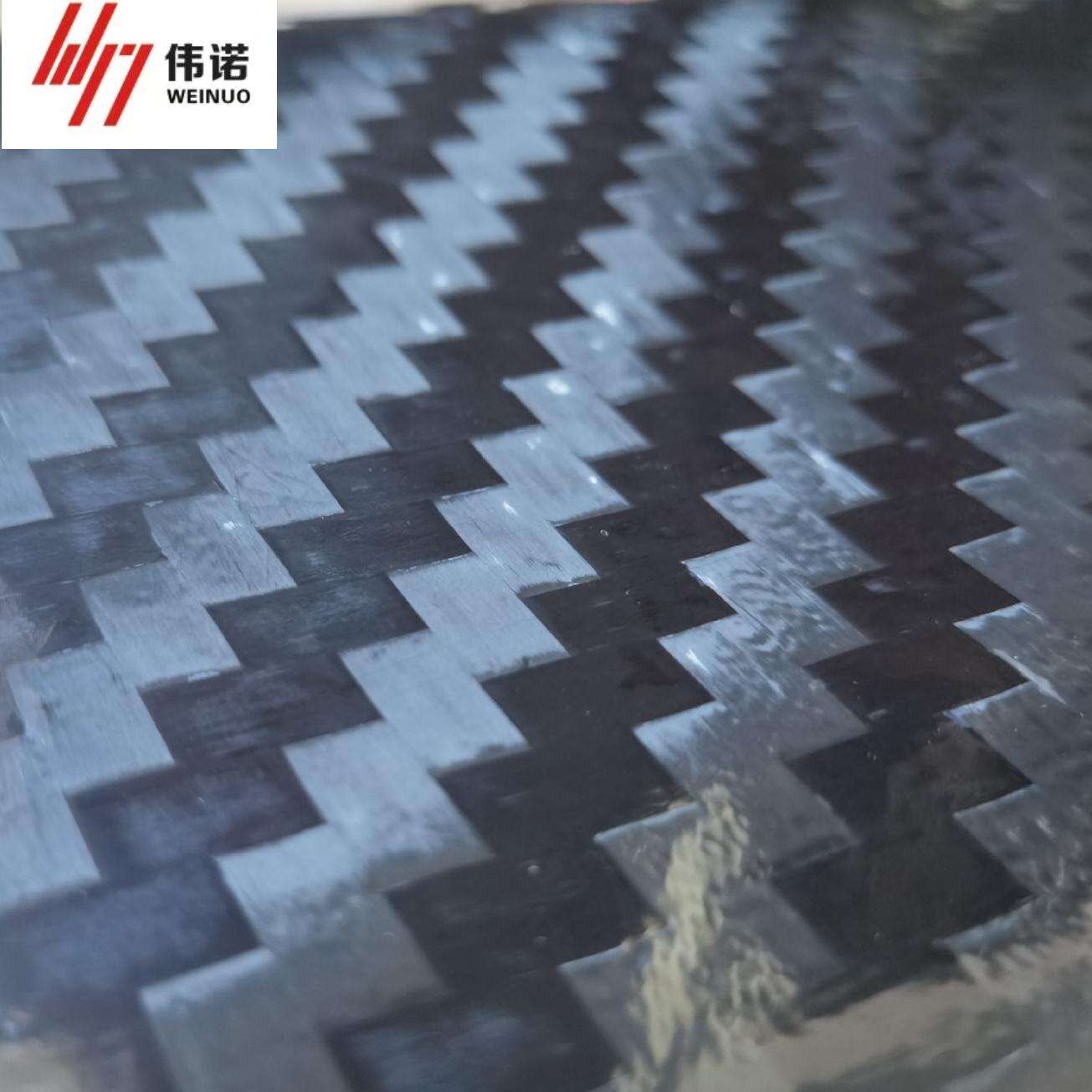

The fiber architecture within prepreg systems can be tailored to specific applications, with various weave patterns and fiber orientations available. This level of control over fiber placement and resin content simply isn't possible with wet layup methods, where resin distribution relies heavily on manual application techniques.

Manufacturing Process Control

The manufacturing process for prepreg carbon fiber involves sophisticated quality control measures at every step. Temperature, pressure, and cure cycles are precisely monitored and controlled in automated systems. This level of control ensures consistent resin content and fiber-to-resin ratios throughout the entire component, eliminating the variability inherent in wet layup processes.

Advanced manufacturing facilities utilize specialized equipment for handling and processing prepreg materials, including temperature-controlled storage systems, automated cutting tables, and precision layup equipment. These systems work together to maintain material integrity and ensure optimal processing conditions.

Performance Advantages in Critical Applications

Mechanical Properties and Structural Integrity

Prepreg carbon fiber systems consistently deliver superior mechanical properties compared to wet layup methods. The precisely controlled resin content results in higher fiber volume fractions, leading to better strength-to-weight ratios and improved stiffness. These enhanced mechanical properties are particularly crucial in aerospace applications, where every gram of weight savings translates to improved fuel efficiency and performance.

The uniformity of prepreg systems also results in better fatigue resistance and long-term durability. Components manufactured using prepreg carbon fiber show more predictable behavior under stress and demonstrate better resistance to environmental factors such as moisture and temperature variations.

Quality Consistency and Reliability

One of the most significant advantages of prepreg carbon fiber is the exceptional consistency it offers from batch to batch. The factory-controlled resin impregnation process eliminates variations in resin content and distribution that are common in wet layup procedures. This consistency is crucial for industries where part reliability and repeatability are essential, such as in medical equipment manufacturing or aerospace components.

Quality control documentation and traceability are also enhanced with prepreg systems, as material properties are verified and documented before the manufacturing process begins. This level of quality assurance is particularly valuable in industries subject to strict regulatory requirements.

Economic Considerations and Production Efficiency

Manufacturing Cost Analysis

While the initial material costs for prepreg carbon fiber may be higher than those for wet layup materials, the total manufacturing costs often prove more favorable when considering the entire production process. Reduced labor requirements, lower scrap rates, and fewer quality control issues contribute to better overall economics in high-volume production environments.

The automated nature of prepreg processing also leads to faster production cycles and more efficient use of manufacturing resources. These efficiency gains become particularly significant in large-scale production scenarios where consistent quality and rapid throughput are essential.

Long-term Value Proposition

The investment in prepreg carbon fiber technology often delivers substantial returns through improved product performance and reduced warranty claims. The superior quality and consistency of prepreg-based components result in longer service life and better customer satisfaction, contributing to stronger brand value and market position.

Additionally, the ability to achieve complex geometries and integrated structures with prepreg systems can lead to part consolidation opportunities, reducing assembly costs and improving overall product reliability.

Environmental and Sustainability Impact

Waste Reduction and Material Efficiency

Prepreg carbon fiber systems typically generate less waste than wet layup processes, as the precise resin content eliminates excess resin usage and associated disposal issues. The ability to optimize material utilization through automated cutting and kitting processes further reduces waste and improves sustainability metrics.

The controlled manufacturing environment required for prepreg processing also results in lower volatile organic compound (VOC) emissions compared to open molding processes used in wet layup applications. This environmental advantage is becoming increasingly important as industries face stricter environmental regulations.

Lifecycle Considerations

The durability and longevity of prepreg carbon fiber components contribute to better lifecycle environmental performance. The extended service life of these components reduces the need for replacement parts and associated manufacturing impacts. Additionally, ongoing research into recycling technologies for prepreg carbon fiber materials is opening new possibilities for end-of-life material recovery.

Frequently Asked Questions

What storage conditions are required for prepreg carbon fiber materials?

Prepreg carbon fiber materials typically require storage at low temperatures (usually around -18°C) to prevent premature curing. Once removed from cold storage, the material must be allowed to warm to room temperature before use to prevent moisture condensation issues. Proper material management and tracking of out-time is essential for maintaining optimal material properties.

How does the cure cycle affect the final properties of prepreg carbon fiber parts?

The cure cycle, including temperature ramps, dwell times, and pressure application, is critical for achieving optimal mechanical properties in prepreg carbon fiber components. Precise control of these parameters ensures proper resin flow, complete cure, and minimal void content in the finished part. Deviations from recommended cure cycles can result in reduced mechanical properties or quality issues.

What are the key considerations for transitioning from wet layup to prepreg processes?

Transitioning to prepreg carbon fiber processing requires investment in appropriate equipment, including freezer storage, automated cutting systems, and suitable curing equipment. Staff training in proper material handling and processing techniques is essential. Additionally, facility modifications may be necessary to maintain the required environmental conditions for prepreg processing.