No.80 Changjiang Mingzhu Road, Houcheng Street, Zhangjiagang City, Jiangsu Province, China +86-15995540423 [email protected] +86 15995540423

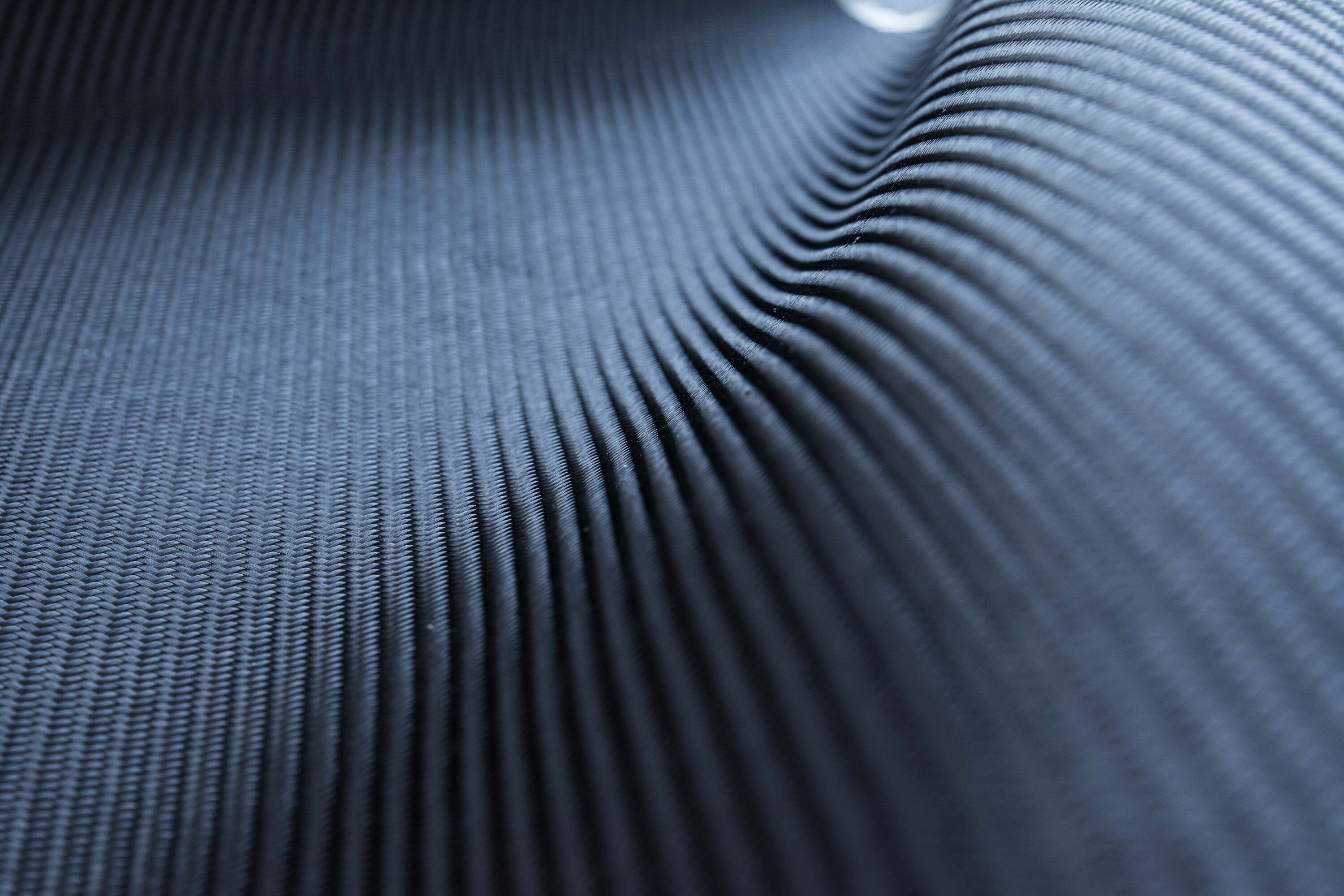

Against the backdrop of accelerating global energy transition toward low-carbon and clean solutions, materials are quietly emerging as the key driver of energy technology advancement. From wind turbine blades stretching over a hundred meters to high-pressure hydrogen storage tanks, carbon fiber is increasingly featured in core equipment for new energy sources, gradually evolving from a "high-end material" to an essential standard in the energy sector.

What capabilities enable this seemingly ordinary black fiber to occupy an irreplaceable position in critical sectors like wind power and hydrogen energy?

Wind turbine blades impose extreme demands on materials.

Wind power, as one of the most mature forms of clean energy today, continues to evolve toward larger megawatt capacities and longer blades. Longer blades increase the swept area, theoretically boosting power generation efficiency. However, this trend poses extreme challenges to material performance.

Traditional glass fiber blades often suffer from structural and fatigue issues due to excessive self-weight as blade lengths increase. Carbon fiber, with its outstanding specific strength and specific modulus advantages, offers a superior solution for achieving "weight reduction and efficiency enhancement" in wind turbine blades.

The incorporation of carbon fiber-reinforced composites in critical load-bearing areas like the main spar and reinforcement zones significantly reduces overall blade weight while substantially enhancing stiffness and fatigue life. This not only facilitates further breakthroughs in blade length but also reduces transportation, installation, and operational loads for the entire turbine, paving the way for the development of offshore wind power and wind farms in low-wind-speed regions.

Hydrogen Storage Tanks: The Core Support for Lightweighting and Safety

If wind power represents the "generation side" of new energy, then hydrogen energy is a crucial direction for energy storage and utilization. Within the hydrogen energy system, the safe and efficient storage of high-pressure hydrogen remains an unavoidable key challenge.

Current mainstream Type III and Type IV high-pressure hydrogen storage tanks almost exclusively utilize carbon fiber composite winding structures. Compared to traditional metal storage tanks, carbon fiber hydrogen tanks demonstrate significant advantages across multiple dimensions:

(1) Lighter weight: Significantly reduced weight for equivalent hydrogen storage capacity, enhancing overall vehicle or system efficiency.

(2) Superior pressure resistance: Capable of meeting high-pressure storage demands at 35MPa, 70MPa, and beyond.

(3) Corrosion and fatigue resistance: Resistant to hydrogen embrittlement, ensuring long-term safety and reliability.

Consequently, carbon fiber has become an indispensable core material in fuel cell vehicles and hydrogen storage/transportation systems.

Why is carbon fiber so "special"?

The performance advantages of carbon fiber stem from its unique microstructure.

Carbon atoms are arranged in a highly oriented manner, forming a graphite-like crystalline structure; despite fiber diameters typically only 5–10 micrometers, they can withstand extremely high tensile loads. Simultaneously, through surface treatment and fabric structure design, carbon fiber can form stable bonds with resin systems, meeting the structural demands of various energy equipment.

It is precisely this structural and process design flexibility that enables carbon fiber composites to achieve an unparalleled balance between strength, stiffness, weight, and durability.

Historically, the high cost of carbon fiber significantly limited its application expansion. However, in recent years, technological advancements and increased application scale have gradually altered this landscape:

(1) Mature large-tow carbon fiber technology has driven continuous unit cost reductions.

(2) Continuous optimization of precursor materials and manufacturing processes has boosted production efficiency.

(3) Recycling and reuse technologies are steadily improving.

(4) Growing demand in the energy sector is driving large-scale industrial development.

Considering both comprehensive performance and total lifecycle costs, the application of carbon fiber in energy equipment is becoming increasingly economically viable.

Beyond wind power and hydrogen energy, the scope of energy applications continues to expand.

Beyond wind turbine blades and hydrogen storage tanks, the application boundaries of carbon fiber in the energy sector continue to expand, such as:

(1) Photovoltaic mounting structures and structural components

(2) Structural and protective components in nuclear power equipment

(3) Corrosion-resistant components in ocean energy equipment

(4) Transmission and grid reinforcement structures

It is foreseeable that as new energy technologies continue to advance, carbon fiber will play a role in more critical areas.

From wind turbine blades spinning against the wind to hydrogen storage tanks operating under pressure, carbon fiber is reshaping the material logic of energy equipment. It represents not only a lighter, stronger material choice but also embodies the shared pursuit of efficiency, safety, and reliability in the new energy era.

As carbon fiber transitions from a "premium option" to an "energy industry standard," this shift reflects not only advances in materials science but also an inevitable choice within the energy transition process.

In future energy systems, carbon fiber may become as ubiquitous as steel is today—yet lighter, more resilient, and better aligned with sustainable development goals.

Copyright © 2026 Zhangjiagang Weinuo Composites Co., Ltd. All rights reserved