No.80 Changjiang Mingzhu Road, Houcheng Street, Zhangjiagang City, Jiangsu Province, China +86-15995540423 [email protected] +86 15995540423

When people discuss the "material revolution," carbon fiber is often a hot topic. This feather-light yet steel-strong marvel has transformed manufacturing in aerospace, automotive, and sports equipment industries. Now, a more advanced form of carbon fiber—multi-axial carbon fiber fabric—is quietly rewriting the rules for high-end structural component production.

Why does traditional carbon fiber have limitations?

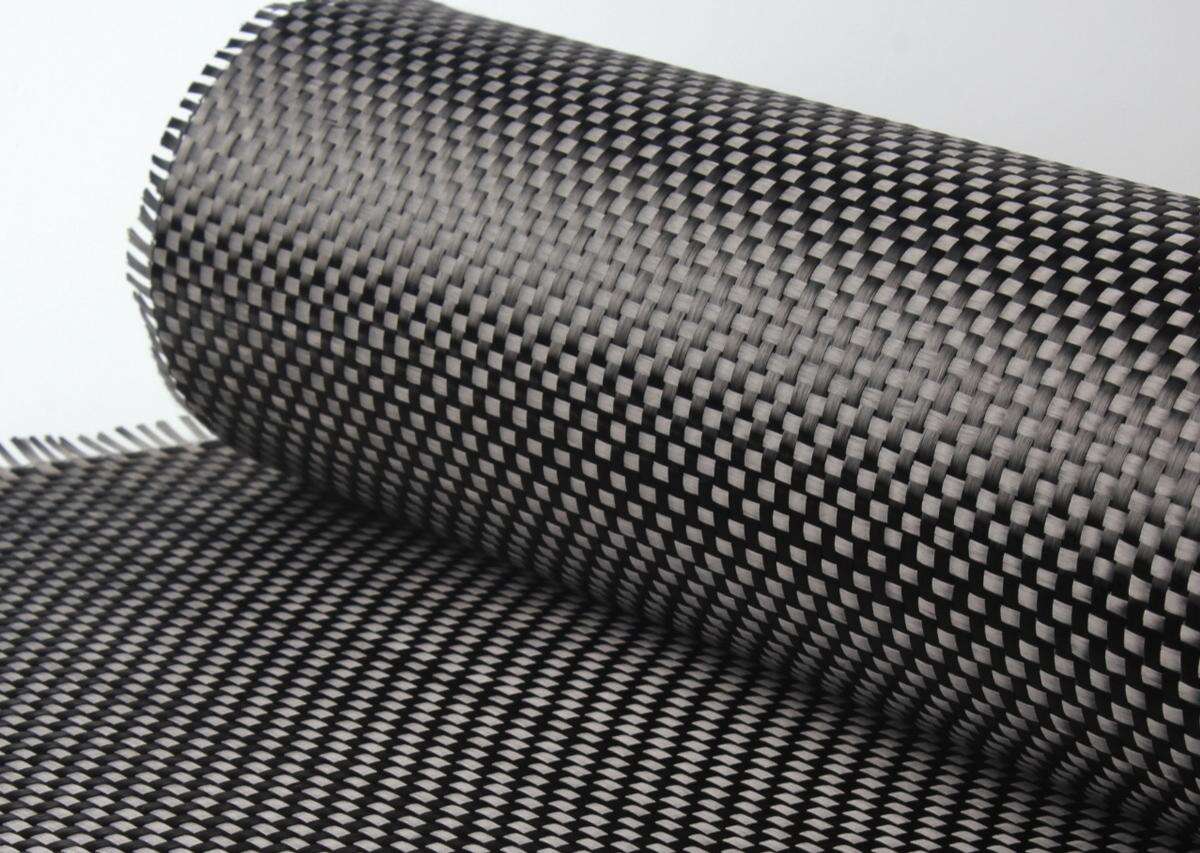

Traditional unidirectional carbon fiber fabrics or simple plain-weave carbon fiber fabrics, while possessing high strength, exhibit significant shortcomings when subjected to multidirectional forces. This is akin to a sheet of paper—it tears easily along its grain, but when pulled from multiple angles, it demonstrates distinct strength characteristics. In the real world, structural components rarely endure forces from a single direction alone.

Innovations in Multi-Axis Fabrics

Multi-axial carbon fiber fabrics create truly "three-dimensional" material properties by layering and stitching fiber layers at specific angles—typically 0°, 90°, and ±45°. This design delivers exceptional strength and stiffness in all directions. Key advantages include:

→Comprehensive Mechanical Properties

Multi-axial fabrics deliver balanced strength whether subjected to longitudinal tension, transverse shear, or torsion.

→Reduced Laminate Layers

Traditional carbon fiber requires multiple stacked layers to achieve multi-directional strength, whereas multi-axial fabrics integrate multi-directional fibers within a single layer.

→Greater Design Freedom

Engineers can customize fiber angles to specific load paths, enabling true "design-on-demand."

→Superior Impact Resistance

The multidirectional fiber distribution better absorbs and disperses impact energy.

Industry Application Examples

→Wind Power Generation

Extra-long wind turbine blades must withstand complex aerodynamic loads. Multi-axial carbon fiber fabrics offer an ideal solution, reducing weight while ensuring structural integrity.

→Aerospace

The use of multi-axial carbon fiber in aircraft fuselage and wing skins not only reduces weight but also enhances fatigue life and damage tolerance.

→High-End Automotive

From Formula 1 race cars to supercars, multi-axial carbon fiber enables lighter, safer body structures while meeting complex surface forming requirements.

→Sports Equipment

High-performance bicycle frames, rowing oars, and skis utilize multi-axial fabrics to significantly enhance durability while maintaining lightweight construction.

Future Outlook

With continuous advancements in manufacturing technology and further reductions in costs, multi-axial carbon fiber fabrics will see increasingly widespread application. We may witness:

(1) Smarter "adaptive" composites capable of adjusting performance based on real-time loads

(2) Integration with 3D printing technology to achieve more complex integrated structures

(3) Large-scale adoption in emerging fields like renewable energy and sustainable construction

In modern engineering, where the pursuit of ultimate performance and efficiency reigns supreme, multi-axial carbon fiber fabrics represent a fundamental shift in material design philosophy—from "using existing materials" to "designing required materials." This is not merely an evolution of materials but a revolution in engineering thinking.

For designers and engineers seeking to push performance boundaries, multi-axial carbon fiber fabrics are not merely an option—they are becoming the "new standard" for high-end structural component design. In this era of lightweight, high-strength, multifunctional materials, mastery of this technology grants a decisive competitive edge.

About Us (Weinuo)

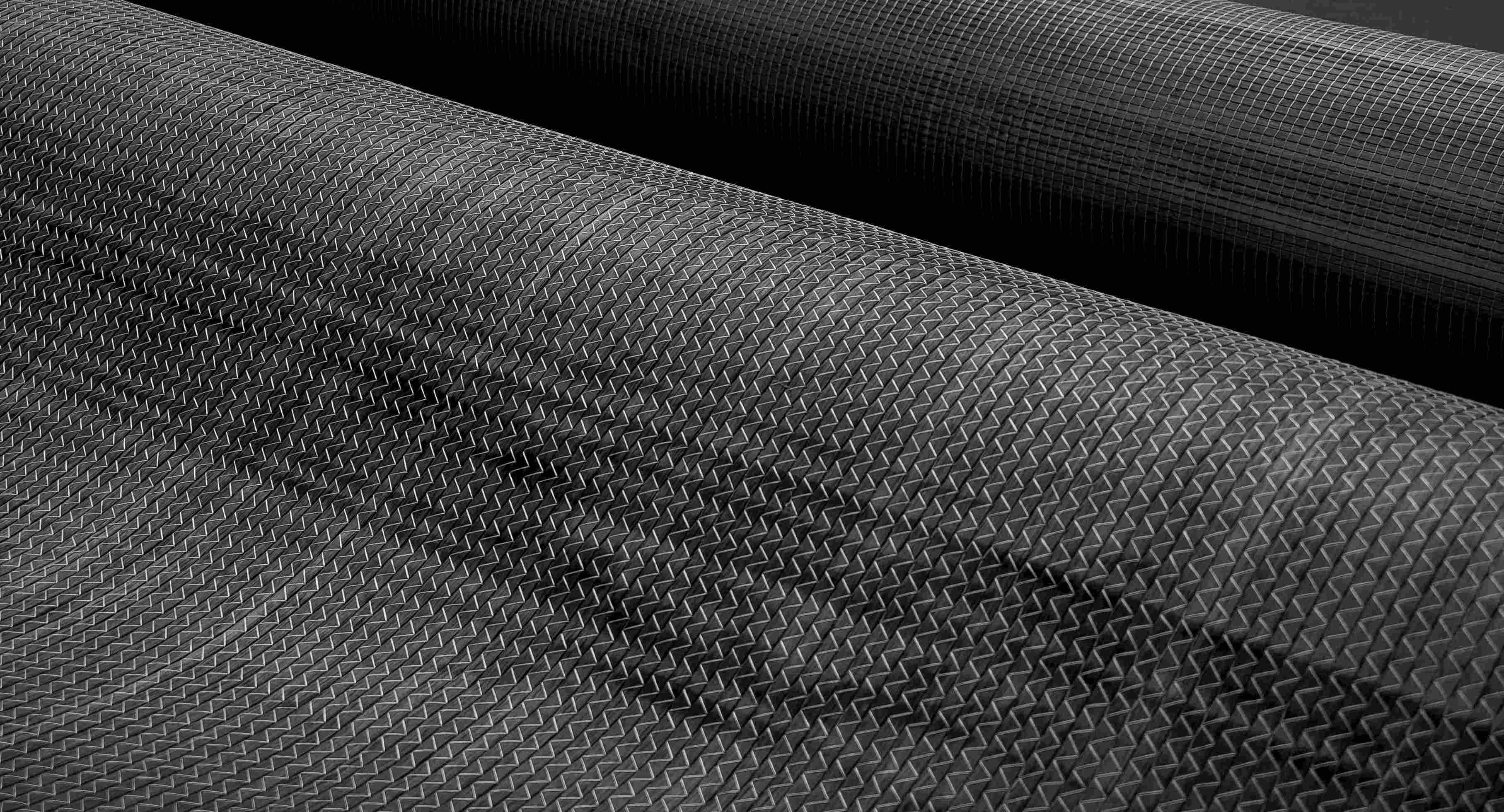

As carbon fiber increasingly becomes the standard configuration for energy equipment, the stable supply capability and engineering level of the material itself are equally critical. As one of the few privately-owned carbon fiber fabric manufacturers in China equipped with multi-axis warp knitting machines, our company (Zhangjiagang Weinuo Composite Materials Co., Ltd.) has long specialized in the R&D and production of multi-axis carbon fiber fabrics and related composites. We consistently produce multi-axis structural fabrics in configurations such as 0° / ±45° / 90°, meeting the practical demands for multi-directional load reinforcement in wind power, hydrogen energy, and various structural components.

Leveraging mature equipment configurations and continuously optimized production processes, we achieve a balanced approach to large-scale production and cost control while ensuring consistent product performance and reliability. This enables our high-performance carbon fiber materials to deliver competitive engineering value. We aim to provide long-term, sustainable material support for the structural upgrading of energy equipment through stable production capacity, reliable quality, and pragmatic solutions.

Copyright © 2026 Zhangjiagang Weinuo Composites Co., Ltd. All rights reserved