No.80 Changjiang Mingzhu Road, Houcheng Street, Zhangjiagang City, Jiangsu Province, China +86-15995540423 [email protected] +86 15995540423

In the world of carbon fiber composites, "chopped carbon fiber" and "continuous carbon fiber" are two indispensable keywords. Both serve as carbon fiber reinforcement materials, yet they exhibit distinctly different "personalities" in terms of structural morphology, mechanical properties, processing methods, and application scenarios.

So, what are the key performance differences between the two? And how should one choose between them in practical applications? This article will help you understand them clearly at a glance.

Different fiber morphologies

Chopped Carbon Fiber

This process involves cutting continuous carbon fibers into short fibers ranging from several millimeters to tens of millimeters in length, typically 0.1–12 mm. These fibers appear as short segments or fragments, resembling rice grains or columnar bundles.

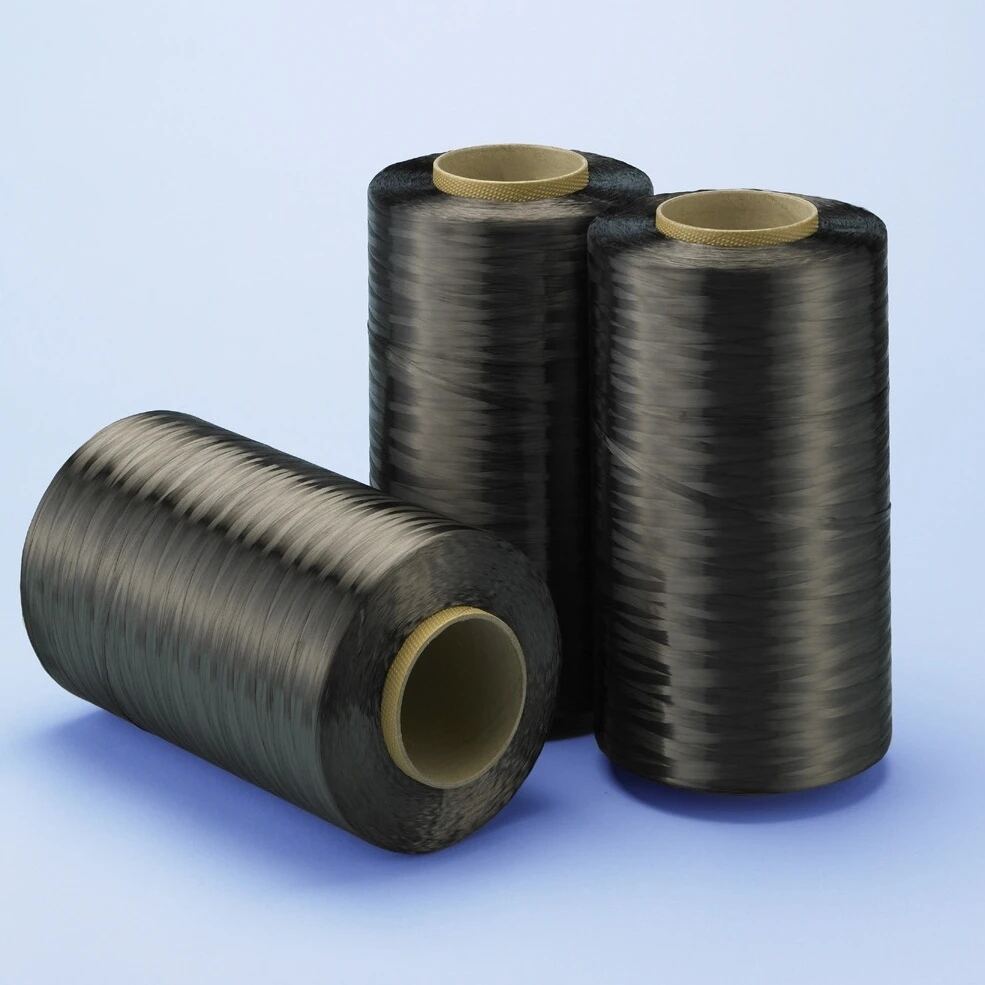

Continuous Carbon Fiber

Maintaining the full length of the fibers and arranging them in an orderly manner—whether unidirectional, fabric-like, or multi-axial—enables precise load-bearing and transmission. Filament lengths can exceed several kilometers, wound onto bobbins as yarns or filament bundles. A single bundle may contain as many as 1,000 (1k), 3,000 (3k), 12,000 (12k), or even more individual filaments.

Differences in mechanical properties

From the perspective of reinforcement effectiveness:

Chopped Carbon Fiber

(1) Limited fiber length requires frequent load transfer through interfaces

(2) Significant strength enhancement, but far below continuous reinforcement systems

(3) More suited for "performance improvement" rather than "structural load-bearing"

Continuous Carbon Fiber

(1) Continuous fibers with uninterrupted stress pathways

(2) Fully leverages carbon fiber's high strength and modulus properties

(3) Significantly superior tensile, flexural, and fatigue performance compared to chopped carbon fiber

Continuous carbon fiber is suited for "load-bearing structures," while chopped carbon fiber functions more as a "performance enhancer."

Anisotropic Variation: Controllable vs. Balanced

Chopped Carbon Fiber Composites

(1) Random fiber distribution

(2) Relatively balanced isotropic properties

(3) More suitable for complex stress or multi-directional loading environments

Continuous Carbon Fiber Composites

(1) Exhibits pronounced anisotropy

(2) Exceptional performance in the design direction, relatively weaker in non-load-bearing directions

(3) Requires "directional reinforcement" through layup design

This is also a key reason for the widespread use of chopped carbon fibers in injection-molded parts.

Processing Method Differences: Trade-offs Between Efficiency and Performance

Chopped Carbon Fiber

(1) Suitable for injection molding, extrusion, compression molding, and other processes

(2) Hiforming efficiency, ideal for mass production

(3) Easily compatible with thermoplastic resin systems

Continuous Carbon Fiber

(1) Primarily used in lay-up, winding, pultrusion, RTM, and prepreg processes

(2) Complex manufacturing requiring advanced equipment and process control

(3) Better suited for high-performance, customized structural components

If you prioritize production capacity and cost control, chopped fibers offer greater advantages.

If you pursue ultimate performance, continuous fibers are virtually the only choice.

Comparison of Typical Application Scenarios

Common Applications of Chopped Carbon Fiber

Reinforcement of Engineering Plastics (PA, PP, PEEK, etc.)

Automotive Functional Components, Electronic Enclosures

Lightweight Upgrades for Industrial Structural Components

Conductive Coatings/Inks

Concrete Reinforcement and Other Fields

Typical Applications of Continuous Carbon Fiber

Aerospace structural components

Wind turbine blade main spars

High-end sports equipment

High-performance industrial load-bearing components

Copyright © 2026 Zhangjiagang Weinuo Composites Co., Ltd. All rights reserved