No.80 Changjiang Mingzhu Road, Houcheng Street, Zhangjiagang City, Jiangsu Province, China +86-15995540423 [email protected] +86 15995540423

When it comes to carbon fiber, you may have heard of it in the news - rocket arrows, high-speed rail bodies, drones, racing car shells, and even high-end badminton rackets have its figure. This sounds "black technology" full of materials, in the end what is it? Today with the most common words, to take you to recognize the "material world star".

Carbon fiber, essentially "super carbon filaments"

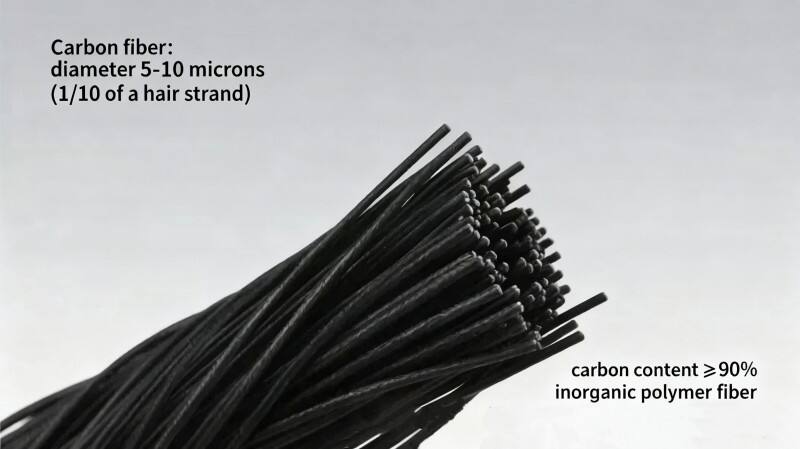

Simply put, carbon fiber is an inorganic polymer fiber containing up to 90% or more carbon. It is neither a metal nor a plastic, but a "crystal of carbon" --a black filament formed by a special process of carbonizing organic fibers (such as polyacrylonitrile and asphalt) at high temperatures to remove impurities.

Appearance: only 5-10 microns in diameter (about 1/10 of a hair strand), looks like black cotton thread or wool to the naked eye, but is more "rigid" to the touch than iron wire.

Characteristics: "Light, strong, resistant, stable".

(1) Strength is 7-9 times that of steel, toughness is far more than glass fiber;

(2) Density of only 1.7g/cm³, lighter than aluminum (aluminum density 2.7g/cm³)

(3) high temperature resistance (can not melt above 2000 ℃), corrosion resistance (not afraid of acids and alkalis), non-conductive (special treatment can be conductive).

Performance "on and off": ridiculously light and surprisingly hard

The greatness of carbon fiber is all "backed up" by three core advantages:

(1)Light as a feather, but stronger than steel:

Density is only 1.7-2.0g/cm³ (1/4 of steel, 2/3 of aluminum alloy), but the tensile strength can reach 3000-7000MPa (more than 10 times that of steel), and a finger-thick carbon fiber rope can lift several tons of cars.

(2)Rigidity explosion, stable as a rock:

Modulus of elasticity (a measure of rigidity) reaches 200-600GPa, almost no deformation when subjected to force, using it as a satellite support, can maintain a precise attitude in space.

(3)"anti-build" attributes pull full:

High temperature resistance (inert environment to carry 2000 ℃), acid and alkali resistance (the ocean with decades of non-corrosion), anti-fatigue (repeated force is not easy to break), the metal in front of it have to "concede defeat".

Why is carbon fiber a "national strategic material"?

Carbon fiber is extremely difficult to produce, and there are only a few countries in the world that can mass produce high-end carbon fiber (China, Japan, and the United States mainly). It is not only the "cornerstone" of high-end manufacturing, but also relates to core areas such as aerospace and defense security.

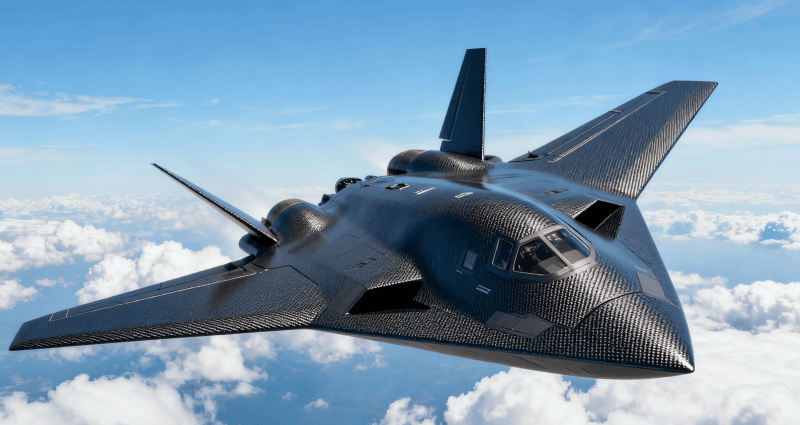

For example, in the military, carbon fiber can be used to manufacture the fuselage of stealth fighters (wave-absorbing), missile body (lightweight to enhance the range); in the field of new energy, the longer the wind turbine blade, the higher the efficiency of power generation, and only carbon fiber can support the 100-meter level of the giant blade.

In recent years, China's carbon fiber industry rapid breakthrough, from dependence on imports to achieve independent mass production, and even in some areas (such as wind power, sporting goods) to occupy a dominant position in the global market.

|

|

|

|

How is carbon fiber "made"?

The greatness of carbon fiber is all "backed up" by three core advantages:

(1)Primary filament preparation

Polyacrylonitrile (PAN), pitch and other raw materials, through the spinning process to make "raw silk" (similar to chemical fiber fiber). This step is the foundation, and the quality of the raw silk directly determines the performance of carbon fiber (China had been "stuck" in this step for a long time).

(2)Carbonization

The raw silk is gradually heated to 1,000-3,000 degrees Celsius in an inert gas (to prevent combustion), which removes elements such as hydrogen and oxygen, leaving only the carbon molecules. After this step, the carbon content of the fiber is raised from 50% to more than 90%, increasing its strength and hardness dramatically.

(3)Subsequent processing

Depending on the application, carbon fibers are woven into cloth, wound into tubes, or combined with resins, metals, etc., to make "carbon fiber composites" (such as what we often call "carbon fiber boards" and "carbon fiber tubes ").

【Carbon Fiber Cold Knowledge】

Q:Why is it black?

A:Graphite structures absorb almost all visible light.

Q:Afraid of fire?

A:Oxidation begins at 400°C in air, but the capsule uses it as a heat shield .

Q: Can it be recycled?

A:BMW has made it possible to recycle car parts from scrap carbon fiber.

Copyright © 2026 Zhangjiagang Weinuo Composites Co., Ltd. All rights reserved