Om Die Omgewingsimpak Van Gevorderde Saamgestelde Materiaal te Begryp

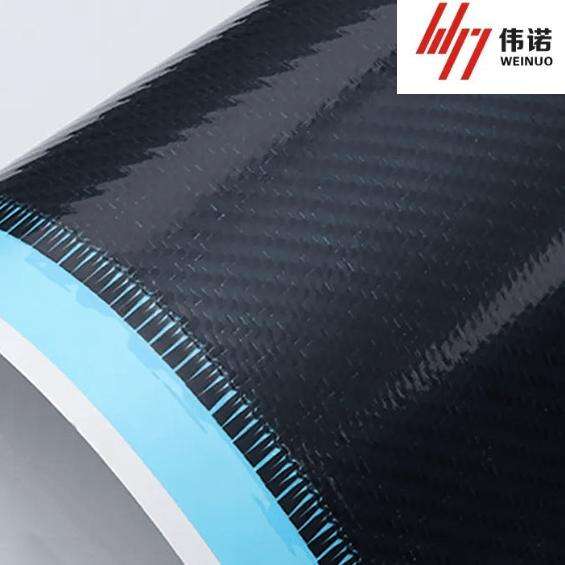

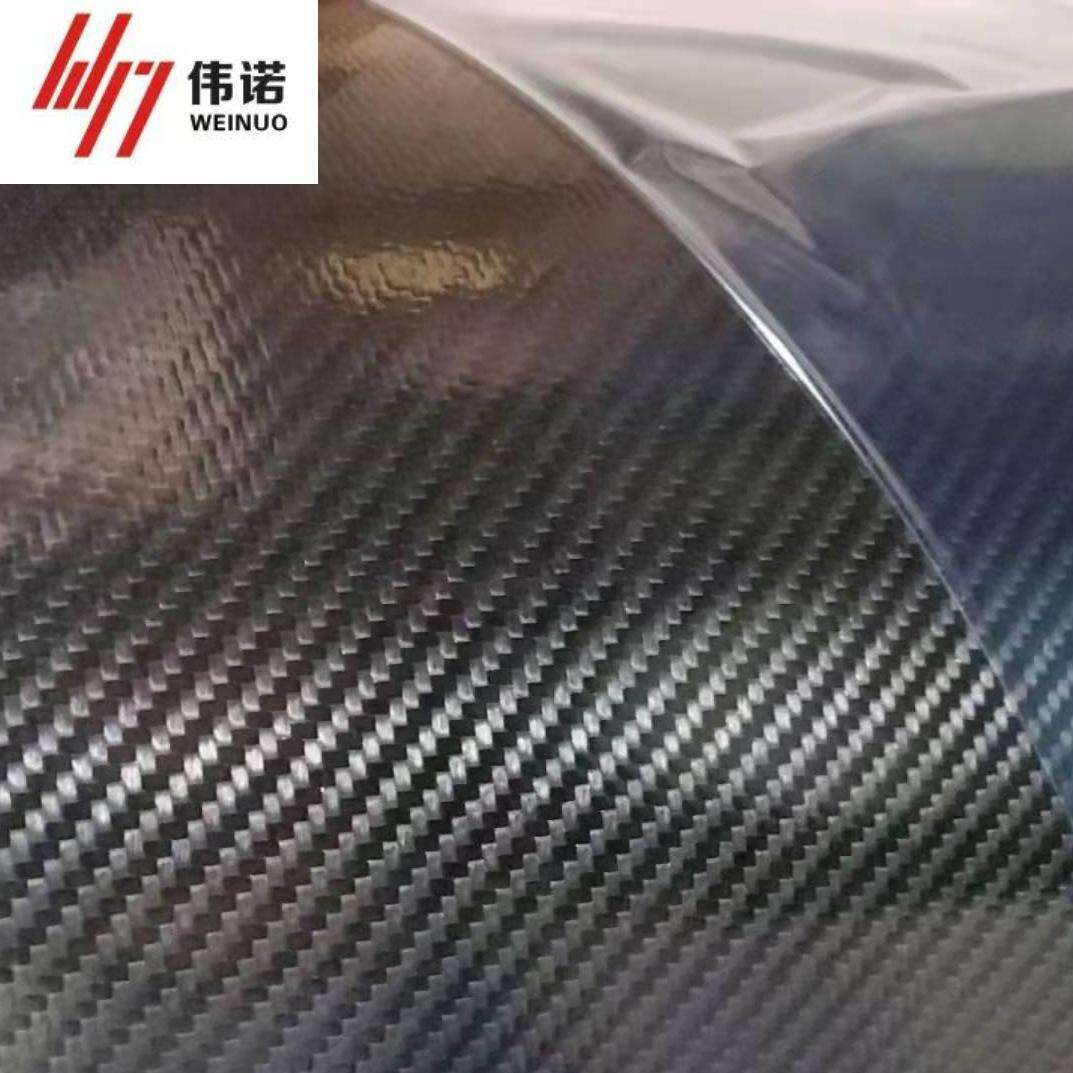

Die lugvaart- en motorindustrieë het toenemend na prepreg koolstofvezel as 'n revolusionêre materiaal vir liggewig, hoë-prestasie toepassings. Alhoewel die tegniese voordele goed gedokumenteer is, verdien die omgewingsimplikasies van voorgedrenkte koolstofvesel sorgvuldige oorweging. Hierdie deeglike ontleding ondersoek die ekologiese aspekte van hierdie gevorderde saamgestelde materiaal regdeur sy lewensiklus, vanaf produksie tot verwydering.

Produksieproses en Omgewingsvoetspoor

Energie-intensiewe Vervaardiging

Die vervaardiging van voorgedrenkte koolstofvesel vereis beduidende energie-inset, hoofsaaklik weens die hoë temperature wat tydens die karboniseringsproses benodig word. Die koolstofvesels moet verhit word tot temperature wat 1 000°C oorskry in 'n suurstofvrye omgewing, wat groot hoeveelhede elektrisiteit verbruik. Hierdie energie-intensiewe proses dra by tot die materiaal se algehele koolstofvoetspoor, wat dit noodsaaklik maak dat vervaardigers hernubare energiebronne soek en produksiëdoeltreffendheid optimeer.

Chemiese Gebruik en Emissies

Die vervaardiging van prepreg-koolstofvesel behels verskeie chemiese prosesse, veral in die voorbereiding van die vooraf-geïmpregneerde harsstelsel. Die poliakrilonitriel (PAN) voorloper wat in koolstofveselproduksie gebruik word, stel vlugtige organiese verbindings (VOS'e) en ander potensieel skadelike emissies vry. Moderne fasiliteite gebruik gevorderde filtrasie- en herwinningstelsels om hierdie omgewingsimpakte te verminder, maar die chemiese voetspoor bly 'n belangrike oorweging.

Waterhulpbronbestuur

Water speel 'n cruciale rol in verskeie fases van die produksieproses van voorgedrenkte koolstofvesel, vanaf koelsisteme tot chemiese verwerking. Vervaardigers moet omvattende waterbestuurstategieë implementeer om verbruik te verminder en besoedeling te voorkom. Geslote-siklusstelsels en waterbehandelingsfasiliteite het standaardkenmerke geword in gevorderde produksiefasiliteite, wat help om die omgewingsimpak op plaaslike water te verminder hulpbronne .

Lewenssiklusassessering en Volhoubaarheid

Materiaalduursaamheid en Lewensduur

ʼN Een beduidende omgewingsvoordeel van prepreg-koolstofvesel is die uitstekende duursaamheid en weerstand teen afbreek. Komponente vervaardig uit hierdie materiaal het gewoonlik ʼn langer nuttige lewensduur as tradisionele alternatiewe, wat die behoefte aan vervanging en die geassosieerde omgewingskoste van die vervaardiging van nuwe dele verminder. Hierdie verlengde lewensduur help om die aanvanklike omgewingsimpak van produksie te kompenseer.

Gewigvermindering Voordelle

Die liggaamsgewig aard van prepreg-koolstofvesel dra by tot beduidende omgewingsvoordele in vervoertoepassings. Wanneer dit in vliegtuie of voertuie gebruik word, lei die verminderde gewig tot laer brandstofverbruik en verminderde emissies gedurende die bedryfslewe van die komponent. Studie het getoon dat vir elke kilogram wat in ʼn vliegtuig verlig word, ongeveer 1 500 liter brandstof oor sy lewensduur bespaar kan word.

Bestuur van einde-lewe en herwinlingsuitdagings

Huidige Herwinnings tegnologieë

Die herwinning van prepreg koolstofvesel bied unieke uitdagings weens sy termosetterharsmatriks. Tradisionele meganiese herwinningsmetodes lei dikwels tot verswakte materiaaleienskappe, wat die toepassings vir herwonne materiaal beperk. Toch toon nuwe tegnologieë soos pirolise en solvolise belofte in die herwinning van hoë-kwaliteit koolstofvesels terwyl die harsmatriks afgebreek word. Hierdie gevorderde herwinningsprosesse word geleidelik meer kommersieel lewensvatbaar.

Afvalreduseringsstrategieë

Vervaardigers implementeer verskillende strategieë om afval tydens die produksie van prepreg koolstofveselkomponente te verminder. Rekenaargesteunde ontwerp en geoutomatiseerde snystelsels help om materiaalgebruik te optimaliseer, terwyl inboesem- en herverwerkingsinisiatiewe verseker dat produksie-afval behoorlik bestuur word. Sekere fasiliteite het byna-nul-afval bereik deur volledige materiaalherwinningsprogramme.

Toekomstige Ontwikkelinge en Groen Innovasies

Bio-gebaseerde Alternatiewe

Navorsing na bio-gebaseerde voorlopers en harsse vir prepreg koolstofvesel toon belowende potensiaal vir die vermindering van omgewingsimpak. Natuurlike materiale soos lignien en sellulose word ondersoek as volhoubare alternatiewe vir tradisionele PAN-voorlopers. Hierdie bio-gebaseerde opsies kan die koolstofvoetspoor van produksie aansienlik verlaag terwyl die materiaal se hoë prestasie-eienskappe behou bly.

Verbeteringe in Energieeffektiwiteit

Tegnologiese vooruitgang in vervaardigingsprosesse bring voortdurend 'n vermindering in die energieverbruik vir prepreg koolstofveselproduksie mee. Mikrogolf-geassisteerde karbonisering en ander innoverende tegnologieë word ontwikkel om energieverbruik te verminder terwyl materiaalkwaliteit behou of verbeter word. Hierdie ontwikkelinge stel belangrike stappe voor na meer volhoubare produksiemetodes.

Gereelde vrae

Hoe vergelyk prepreg koolstofvesel op omgewingsvlak met tradisionele materiale?

Al het voorgedrenkte koolstofvesel 'n hoër aanvanklike omgewingsimpak tydens produksie, lei sy ligte eienskappe en lang bedryfslewe dikwels tot netto omgewingsvoordele in vergelyking met tradisionele materiale, veral in vervoertoepassings waar brandstofdoeltreffendheid krities is.

Wat gebeur met voorgedrenkte koolstofvesel aan die einde van sy lewensiklus?

Tans beland die meeste voorgedrenkte koolstofveselkomponente in vullisstorte, maar gevorderde herwinningstegnologieë word ontwikkel en toegepas om die waardevolle koolstofvesels terug te wen en te hergebruik. Dit sluit termiese ontbinding (pirolise), solvolise en meganiese herwinningmetodes in.

Is daar omgewingsvriendelike alternatiewe vir tradisionele voorgedrenkte koolstofvesel?

Navorsing word tans gedoen na biobasiese voorlopers en hars wat meer volhoubare alternatiewe kan bied. Daarbenewens ontwikkel vervaardigers hibriede materiale wat koolstofvesel met natuurlike vesels kombineer om die omgewingsimpak te verminder terwyl prestasie-eienskappe behou word.