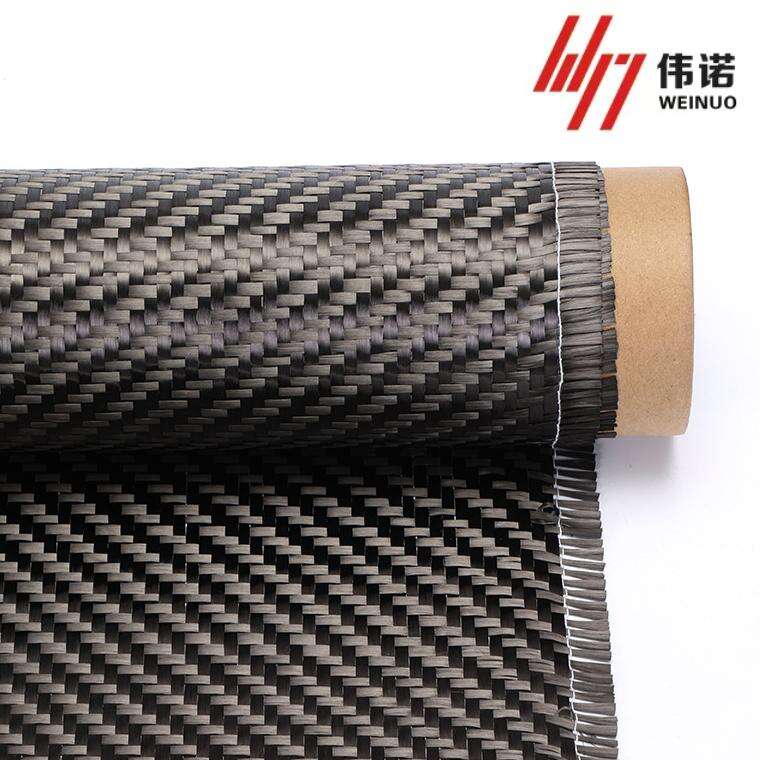

3k 200g carbon fiber fabric

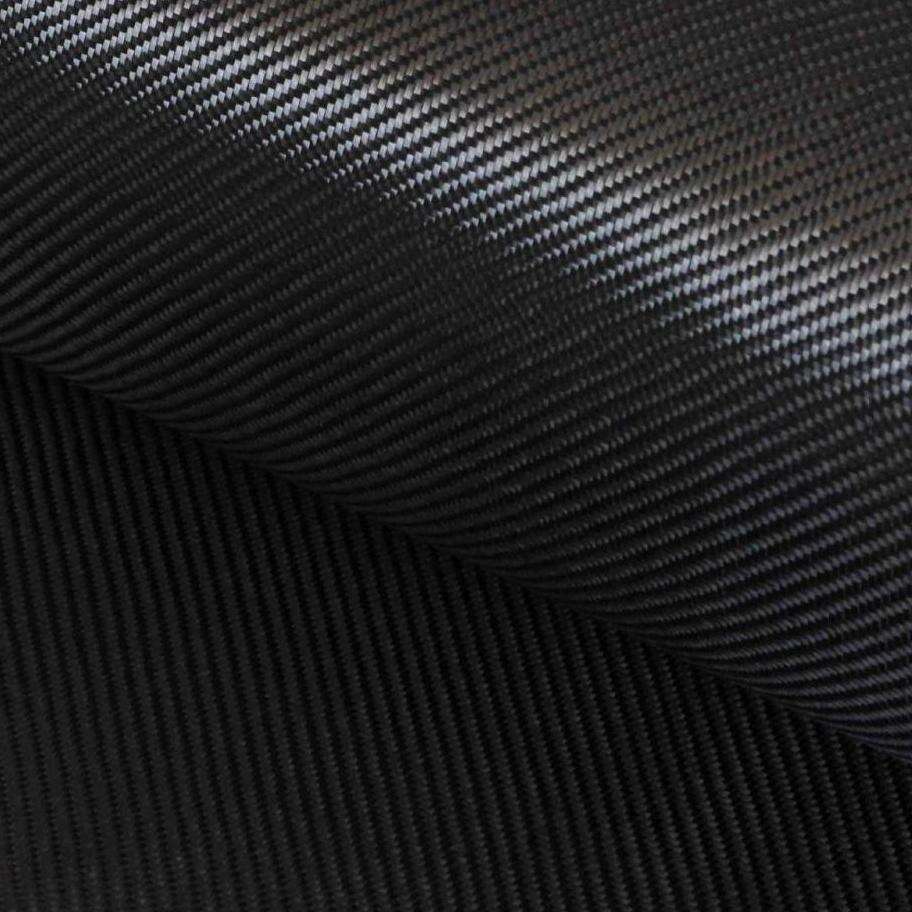

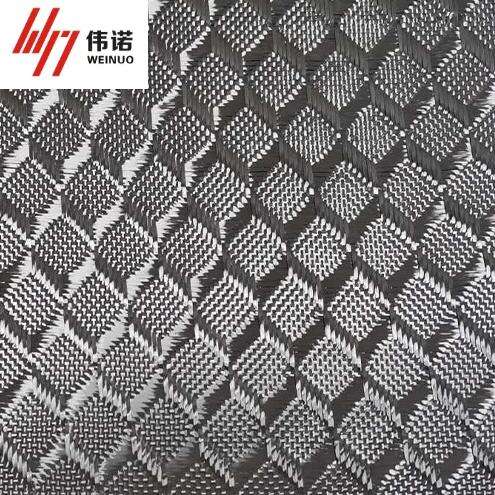

The 3k 200g carbon fiber fabric represents a cutting-edge composite material that combines lightweight properties with exceptional strength. This specialized fabric features a distinctive weave pattern utilizing 3000 carbon filaments per tow, creating a balanced and uniform structure that weighs 200 grams per square meter. The fabric's construction allows for optimal resin penetration during composite manufacturing processes, ensuring superior structural integrity in the final product. Its versatility makes it ideal for various applications across multiple industries, from automotive components to aerospace structures. The fabric exhibits remarkable tensile strength and modulus properties, while maintaining flexibility during the layup process. Engineers and manufacturers particularly value its consistent quality and predictable performance characteristics. The 3k weave pattern provides an attractive visual finish when used in visible applications, making it popular in both functional and decorative projects. The material's excellent fatigue resistance and dimensional stability contribute to its longevity and reliability in demanding environments. This fabric also demonstrates superior resistance to environmental factors, including UV exposure and chemical interactions, ensuring sustained performance throughout its service life.