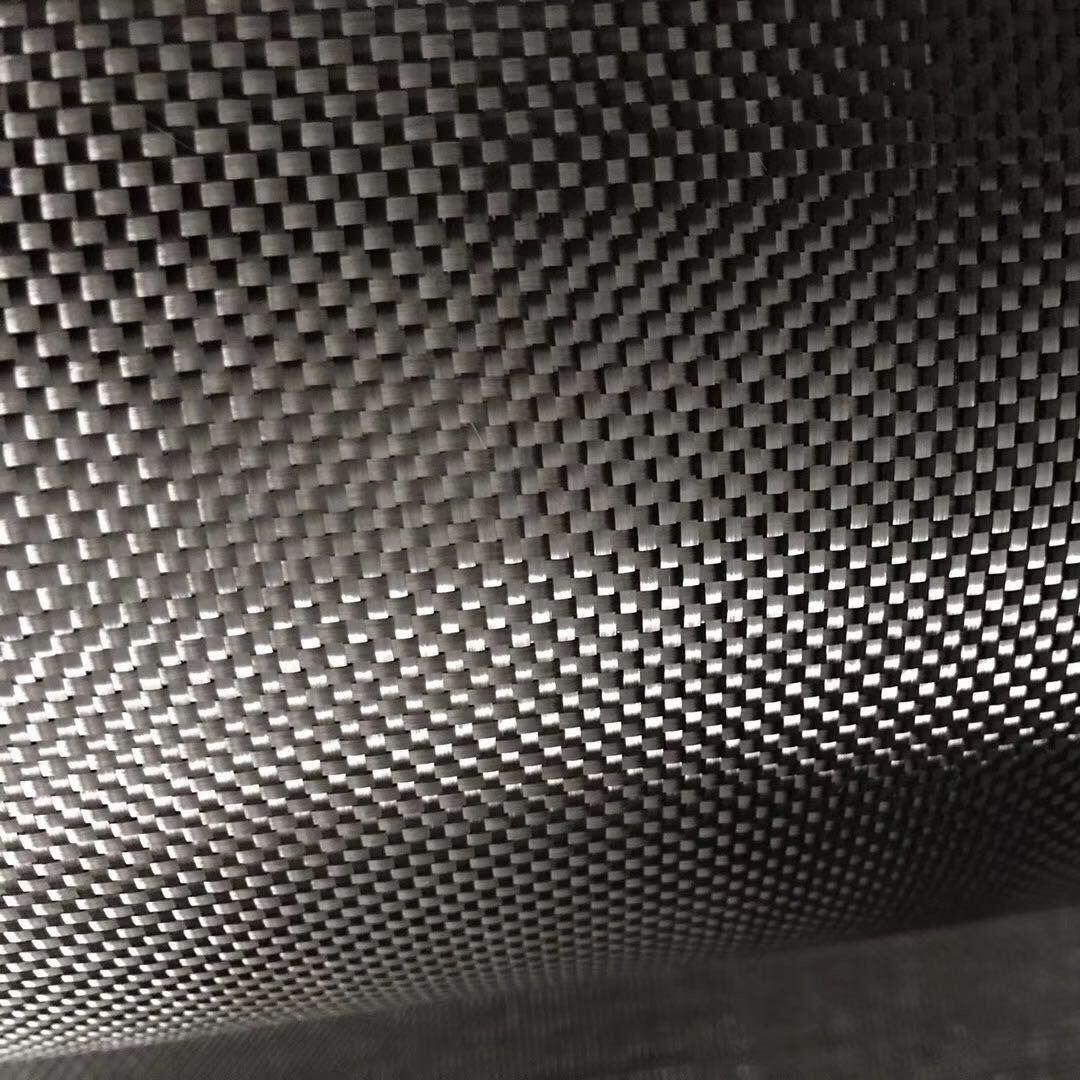

biaxial carbon fiber cloth

Biaxial carbon fiber cloth represents a sophisticated engineered material that features carbon fiber strands woven in two perpendicular directions, typically at 0 and 90 degrees. This specialized arrangement creates a balanced and stable fabric structure that offers exceptional strength and stiffness in both longitudinal and transverse directions. The material's unique construction allows for optimal load distribution and superior mechanical properties, making it an invaluable choice for various high-performance applications. The fabric's balanced weave pattern ensures consistent strength properties across both axes, while its lightweight nature provides an excellent strength-to-weight ratio. The material exhibits remarkable resistance to fatigue, corrosion, and temperature variations, making it ideal for demanding environments. In industrial applications, biaxial carbon fiber cloth serves as a crucial reinforcement material in composite manufacturing, particularly in aerospace, automotive, and marine industries. The fabric's ability to maintain structural integrity while providing design flexibility has made it a preferred choice for engineers and manufacturers seeking to enhance product performance and durability. Additionally, its uniform properties facilitate easier handling and processing during composite layup procedures, resulting in more consistent and reliable end products.