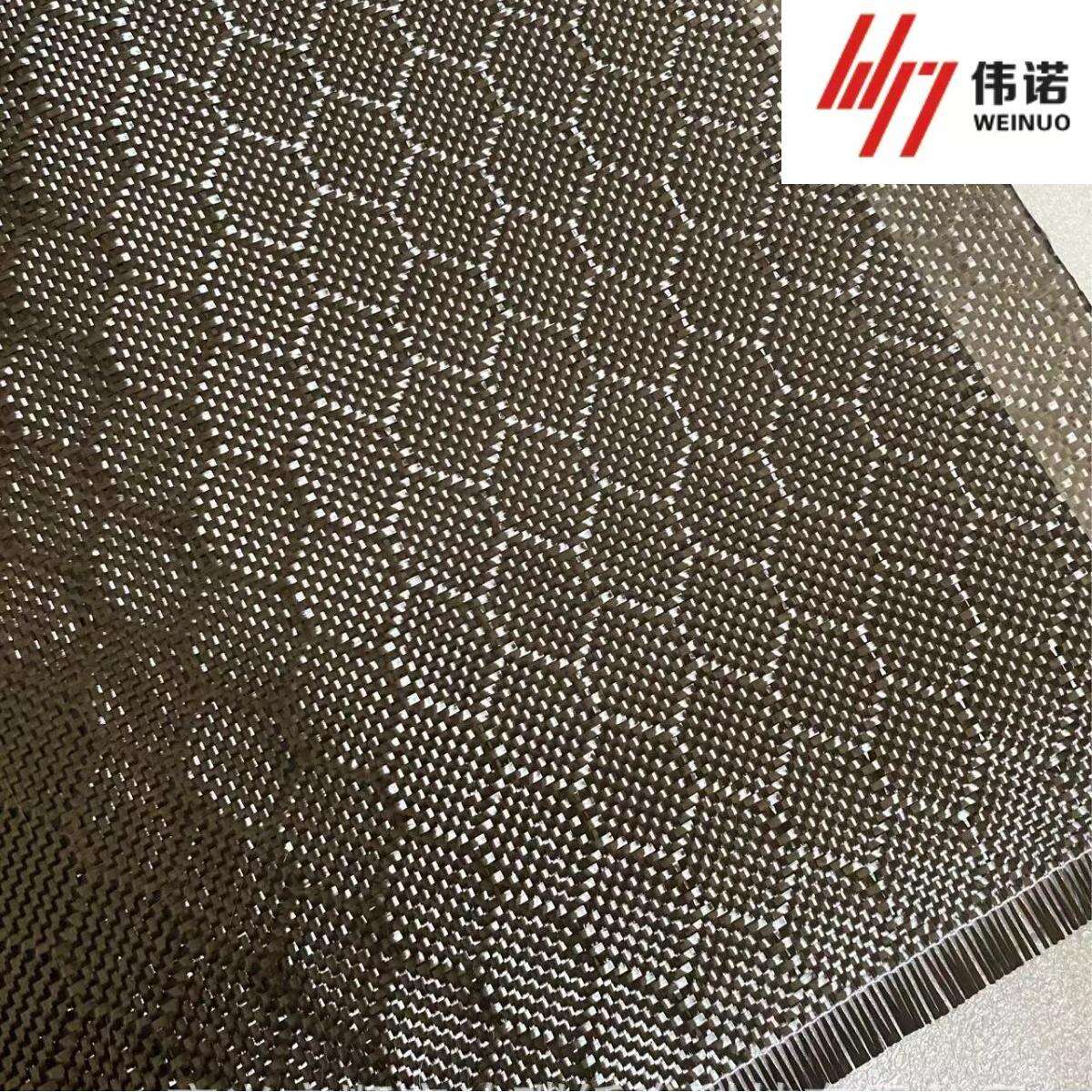

carbon fiber cloth

Carbon fiber cloth represents a revolutionary advancement in material science, combining exceptional strength with remarkably light weight. This versatile material consists of thousands of carbon filaments woven together to create a durable, flexible fabric that maintains superior structural integrity. The manufacturing process involves carefully aligning carbon atoms in a crystalline formation, resulting in a material that exhibits extraordinary tensile strength while remaining incredibly lightweight. Carbon fiber cloth features excellent resistance to environmental factors, including corrosion, UV radiation, and extreme temperatures, making it ideal for both indoor and outdoor applications. The material's unique properties allow it to maintain stability under varying conditions while providing outstanding thermal conductivity and electrical properties. In industrial applications, carbon fiber cloth serves as a crucial component in composite manufacturing, where it's often combined with resins to create high-performance materials used in aerospace, automotive, and construction sectors. Its adaptability enables it to be molded into complex shapes while maintaining its structural properties, making it an invaluable material for modern engineering solutions.