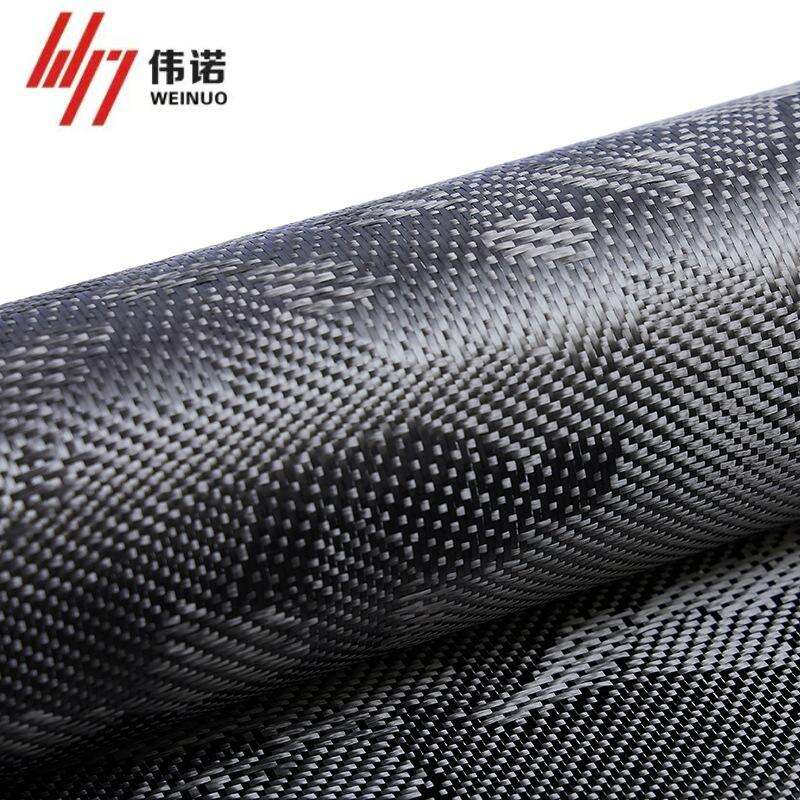

carbon fiber cloth price

Carbon fiber cloth price reflects the complex manufacturing process and superior qualities of this advanced material. The cost varies depending on factors such as weave pattern, fiber grade, and production volume. High-grade carbon fiber cloth typically ranges from $30 to $100 per square yard, with specialized aerospace grades commanding premium prices. The material's exceptional strength-to-weight ratio, thermal resistance, and durability justify its market positioning. Modern manufacturing techniques have helped optimize production costs while maintaining quality standards. The material finds extensive applications in automotive components, sporting goods, industrial reinforcement, and architectural elements. The price point also factors in the specialized equipment and expertise required for production, quality control measures, and raw material costs. Market dynamics, including supply chain conditions and technological advancements, influence pricing trends. Understanding carbon fiber cloth pricing is crucial for project planning and material selection, as it impacts overall project costs and ROI considerations.