carbon fiber cloth tube

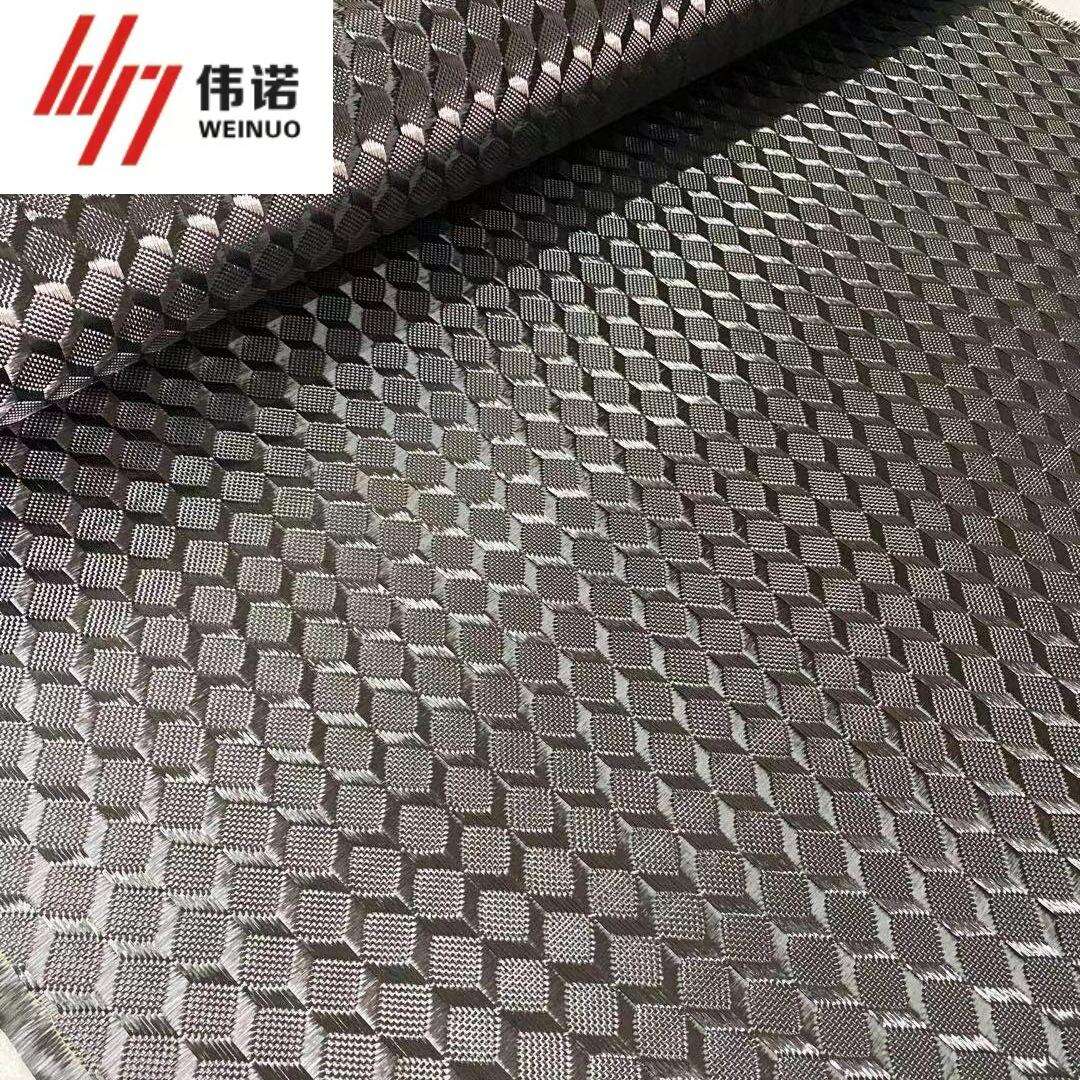

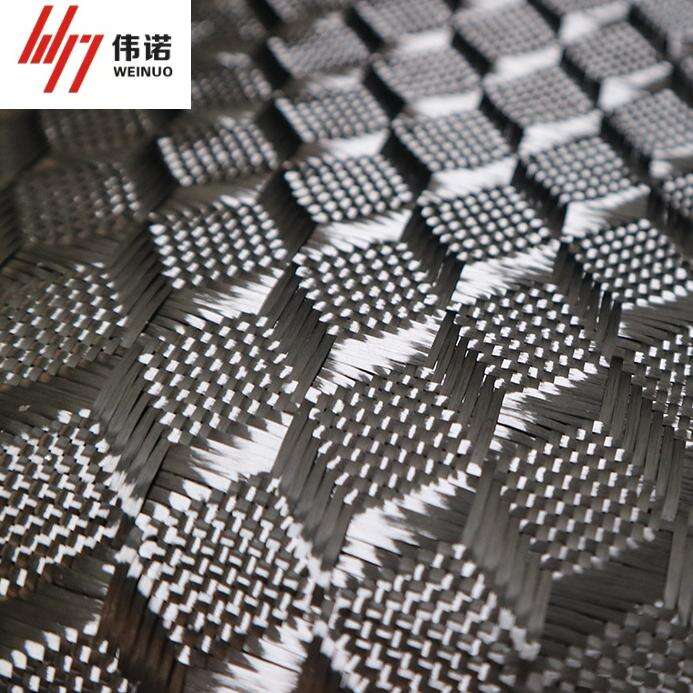

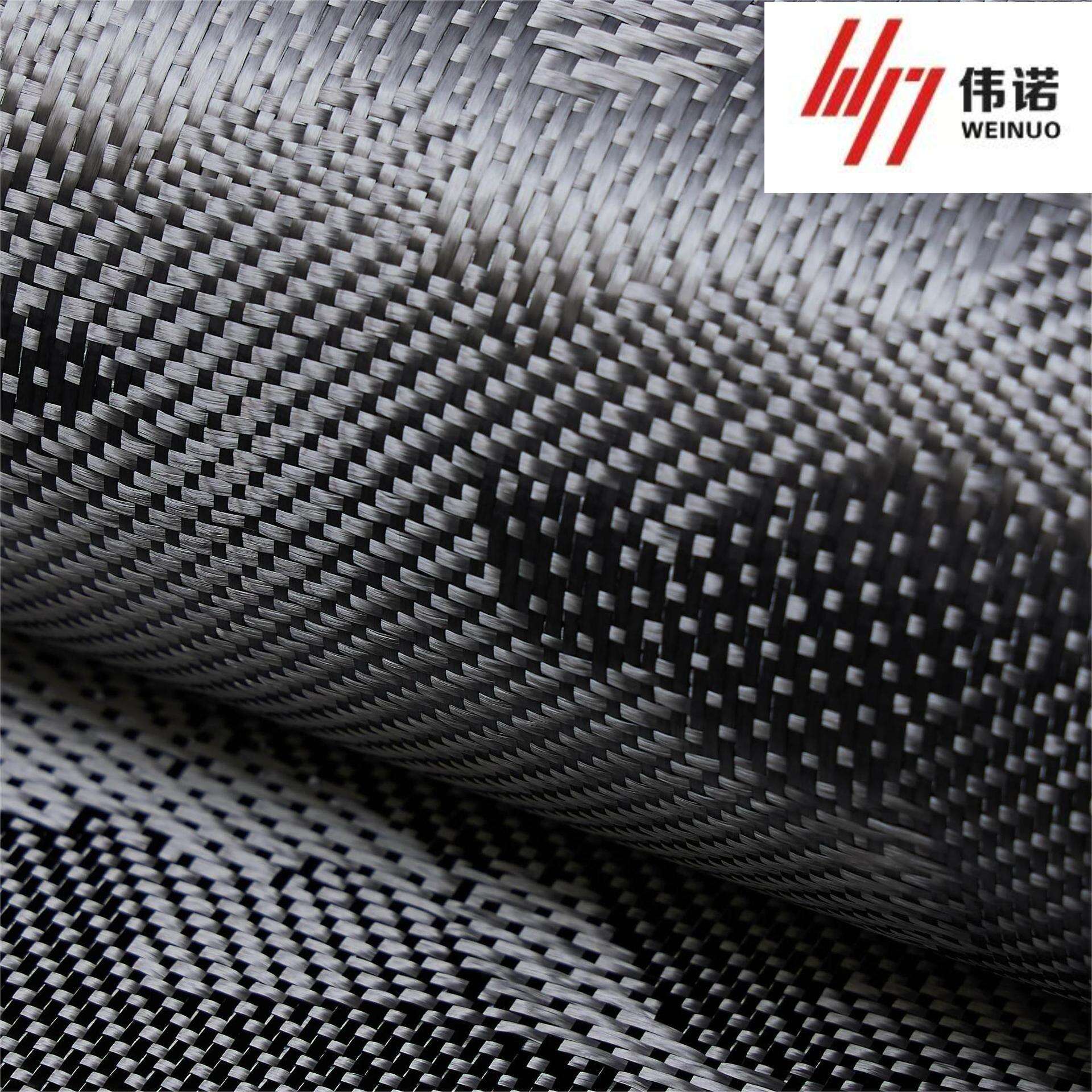

Carbon fiber cloth tubes represent a cutting-edge advancement in composite materials technology, combining exceptional strength with remarkably low weight. These innovative structures consist of woven carbon fiber fabric that has been carefully shaped into tubular forms and impregnated with high-performance resins. The resulting components offer an impressive strength-to-weight ratio that surpasses traditional materials like steel or aluminum. The manufacturing process involves precise layering of carbon fiber cloth, which is then shaped and cured under controlled conditions to create seamless tubes with consistent wall thickness and structural integrity. These tubes find extensive applications across various industries, from aerospace and automotive to sporting goods and industrial equipment. Their inherent resistance to corrosion, fatigue, and environmental factors makes them ideal for demanding applications where durability is paramount. The tubes can be customized in terms of diameter, wall thickness, and length to meet specific engineering requirements, while their surface finish can be tailored to achieve different aesthetic and functional properties. The versatility of carbon fiber cloth tubes extends to their ability to be integrated into complex structural designs, offering engineers and designers unprecedented freedom in creating lightweight yet robust solutions for modern engineering challenges.