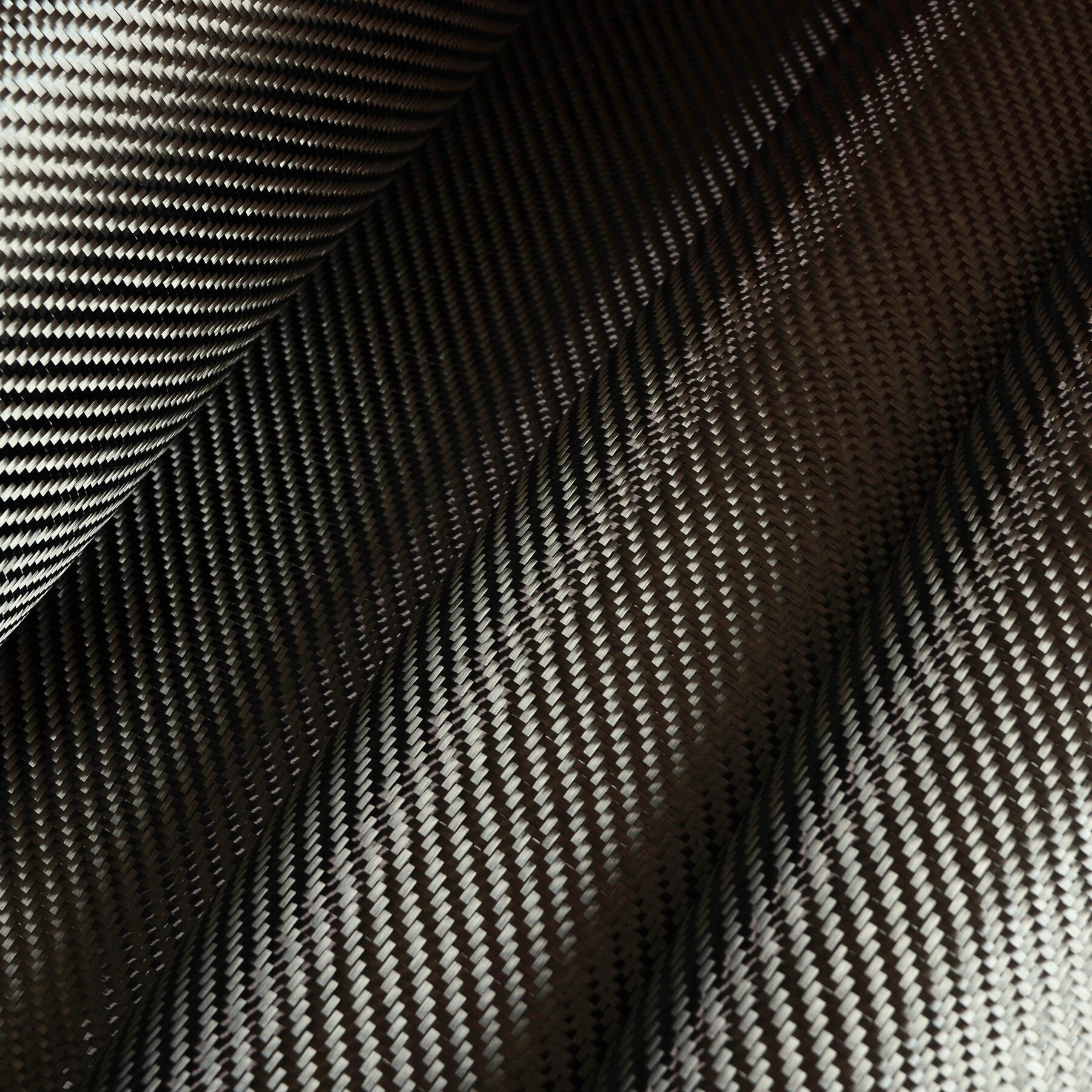

carbon fiber biaxial warp knitted fabrics

Carbon fiber biaxial warp knitted fabrics represent a sophisticated advancement in textile engineering, combining the exceptional strength of carbon fibers with the versatility of warp knitting technology. These specialized fabrics feature carbon fiber strands arranged in two distinct directions, typically at +45 and -45 degrees, creating a balanced and stable structure. The biaxial configuration ensures optimal load distribution and enhanced mechanical properties in multiple directions. The warp knitting process enables the creation of fabric with minimal fiber distortion, maintaining the inherent properties of carbon fibers while achieving excellent dimensional stability. These fabrics exhibit remarkable tensile strength, low weight, and superior resistance to fatigue and corrosion. The manufacturing process involves precision control of fiber orientation and tension, resulting in consistent quality and performance characteristics. The fabric's structure allows for excellent resin penetration during composite manufacturing, ensuring thorough wet-out and strong fiber-matrix bonding. This technical textile finds extensive applications in aerospace, automotive, wind energy, and high-performance sporting goods, where lightweight yet robust materials are essential.