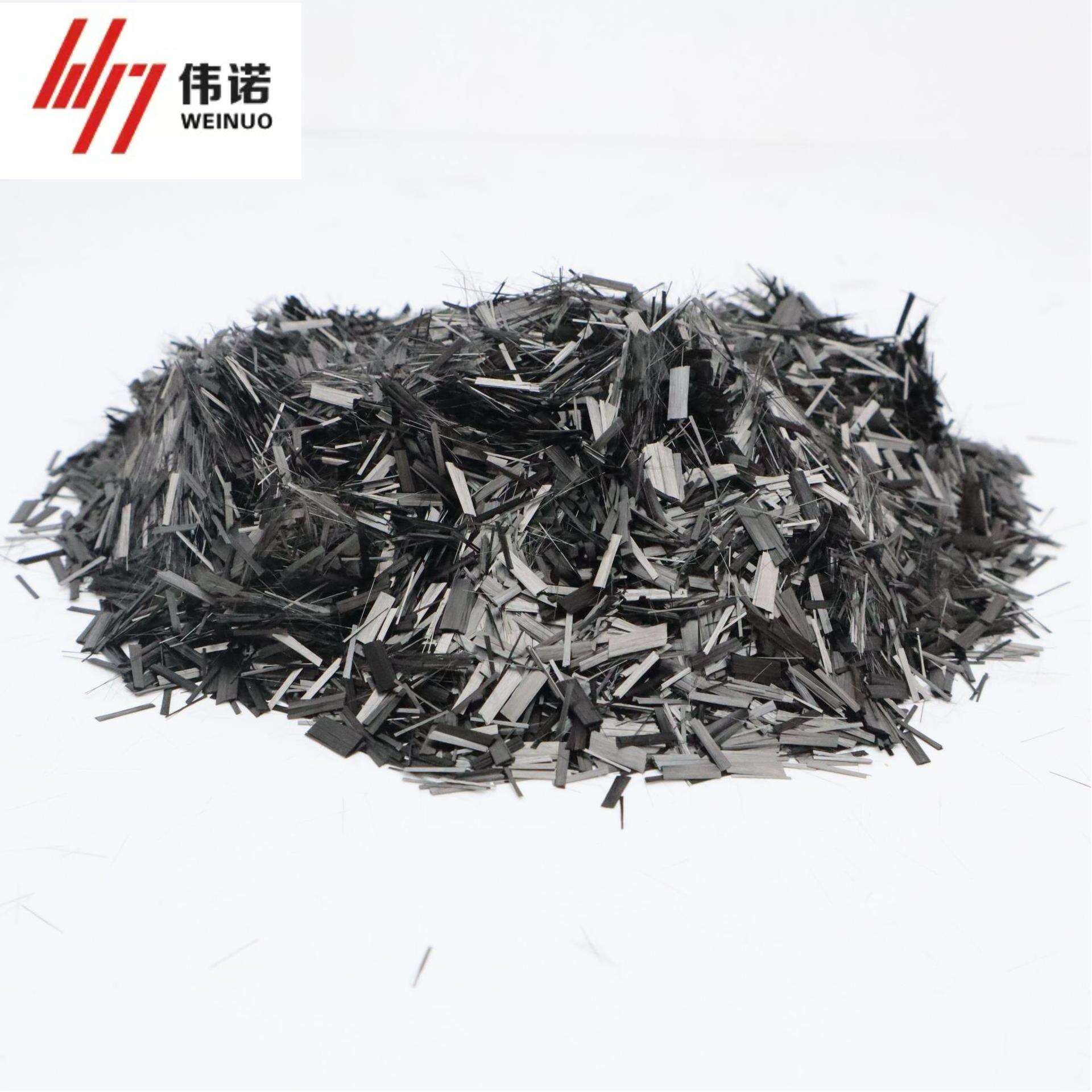

The manufacturing industry increasingly relies on advanced composite materials to meet demanding performance requirements across aerospace, automotive, and industrial applications. Among these materials, chopped carbon fiber stands out as a critical component that delivers exceptional strength-to-weight ratios while maintaining cost-effectiveness in mass production processes. Understanding the factors that influence the consistency and quality of chopped carbon fiber supply has become essential for manufacturers seeking reliable material sourcing and optimal end-product performance.

Modern supply chains face numerous challenges when maintaining consistent quality standards for composite materials. Market volatility, raw material sourcing complexities, and manufacturing process variations all contribute to potential inconsistencies in chopped carbon fiber properties. These fluctuations can significantly impact downstream manufacturing operations, affecting everything from molding cycle times to final product mechanical properties.

Raw Material Quality and Sourcing Considerations

Precursor Fiber Selection and Properties

The foundation of high-quality chopped carbon fiber begins with the selection of appropriate precursor materials. Polyacrylonitrile (PAN) based precursors remain the most common choice for industrial applications due to their excellent conversion efficiency and resulting fiber properties. The molecular weight distribution, spinning conditions, and stabilization parameters of these precursor fibers directly influence the final characteristics of the chopped carbon fiber product.

Variations in precursor quality can manifest as inconsistencies in tensile strength, modulus values, and surface characteristics of the finished chopped fibers. Suppliers must maintain strict quality control protocols during precursor selection and processing to ensure batch-to-batch consistency. Temperature profiles during oxidation and carbonization processes require precise control to achieve uniform fiber properties throughout the production run.

Geographic sourcing of precursor materials also plays a crucial role in supply consistency. Political stability, transportation infrastructure, and regional quality standards all impact the reliability of raw material supply chains. Diversified sourcing strategies help mitigate risks associated with single-source dependencies while maintaining quality standards across multiple supplier relationships.

Carbonization Process Variables

The carbonization stage represents a critical control point where process parameters directly affect the structural integrity and mechanical properties of the resulting carbon fibers. Temperature ramping rates, atmosphere composition, and tension control during carbonization all influence fiber crystallinity and defect formation. Inconsistencies in these parameters can lead to variations in fiber strength and surface morphology that propagate through to the final chopped product.

Advanced process monitoring systems enable real-time adjustment of carbonization parameters to maintain optimal conditions throughout production cycles. However, equipment aging, maintenance schedules, and operator training levels all contribute to potential process drift that can affect product consistency. Regular calibration of monitoring equipment and implementation of statistical process control methods help identify and correct deviations before they impact product quality.

Manufacturing Process Control and Equipment Considerations

Chopping Equipment Performance and Maintenance

The mechanical chopping process itself introduces several variables that can affect the final product consistency. Blade sharpness, cutting speed, and fiber tension during the chopping operation all influence the quality of individual fiber ends and the overall length distribution of the chopped product. Dull or improperly aligned cutting blades can cause fiber end damage, including splitting or crushing that reduces the effectiveness of fiber-matrix bonding in composite applications.

Regular maintenance schedules for chopping equipment ensure consistent cutting performance and minimize variations in fiber length distribution. Automated monitoring systems can track blade wear patterns and cutting force requirements to optimize maintenance intervals. Additionally, proper lubrication and cooling systems prevent thermal effects that could alter fiber properties during the cutting process.

Quality chopped carbon fiber production requires precise control of fiber handling systems to prevent contamination and minimize fiber breakage during processing. Static electricity management, dust collection systems, and controlled environment conditions all contribute to maintaining product integrity throughout the manufacturing workflow.

Length Control and Distribution Management

Achieving consistent fiber length distributions requires careful attention to cutting parameters and downstream handling processes. Variations in cutting speed, feed rate, and fiber bundle tension can result in uneven length distributions that affect the flow characteristics and mechanical properties of the final composite materials. Statistical sampling and measurement protocols help maintain tight control over length specifications across production batches.

Automated sorting and classification systems can remove out-of-specification fibers and ensure consistent length distributions in the final product. These systems utilize advanced optical measurement techniques to rapidly assess individual fiber dimensions and remove non-conforming materials. Integration with production control systems enables real-time feedback for process optimization and quality assurance.

Storage and Handling Impact on Product Consistency

Environmental Control Requirements

Proper storage conditions play a vital role in maintaining the consistency and quality of chopped carbon fiber over time. Humidity control represents one of the most critical factors, as moisture absorption can affect fiber-matrix adhesion and lead to processing difficulties in downstream applications. Temperature fluctuations can also contribute to thermal cycling effects that may impact fiber surface properties and handling characteristics.

Contamination prevention during storage requires careful attention to packaging materials, storage area cleanliness, and handling procedures. Electrostatic discharge protection prevents fiber agglomeration and ensures consistent flow properties during processing. Proper inventory rotation practices help maintain product freshness and prevent aging-related property changes that could affect performance consistency.

Packaging and Transportation Factors

The packaging design and transportation methods used for chopped carbon fiber significantly influence product quality upon delivery to end users. Vibration during shipping can cause fiber settlement and compaction that affects bulk density and flow characteristics. Proper cushioning and container design minimize these effects while protecting against moisture ingress and contamination during transit.

Temperature control during transportation prevents thermal shock effects that could alter fiber properties or cause packaging degradation. Tracking systems enable monitoring of environmental conditions throughout the shipping process, providing valuable data for quality assurance and process improvement initiatives. Clear handling instructions and training for logistics personnel help maintain product integrity from manufacturing facility to end user.

Quality Control and Testing Methodologies

Statistical Process Control Implementation

Effective quality control for chopped carbon fiber requires comprehensive testing protocols that evaluate both individual fiber properties and bulk material characteristics. Tensile testing, length distribution analysis, and surface quality assessment provide critical data for process control and customer specification compliance. Statistical analysis techniques help identify trends and potential issues before they impact product consistency.

Implementation of control charts and process capability studies enables proactive management of quality variations and supports continuous improvement initiatives. Regular correlation studies between process parameters and product properties help optimize manufacturing conditions and reduce variability. Documentation and traceability systems ensure complete quality records for customer requirements and regulatory compliance.

Customer Application Testing and Feedback

End-use application testing provides valuable feedback on the performance consistency of chopped carbon fiber in real-world manufacturing environments. Composite processing trials, mechanical property evaluations, and long-term durability assessments help validate material consistency across different applications and processing conditions. This feedback loop enables suppliers to refine their quality control processes and address specific customer requirements.

Collaboration with customers on application-specific testing protocols helps identify critical quality parameters and establish appropriate specification limits. Regular communication regarding processing experiences and product performance enables rapid response to quality issues and supports continuous improvement efforts throughout the supply chain.

Supply Chain Management and Vendor Relations

Supplier Qualification and Auditing

Maintaining consistent chopped carbon fiber quality requires careful evaluation and ongoing monitoring of supplier capabilities and quality systems. Comprehensive supplier audits assess manufacturing processes, quality control procedures, and technical capabilities to ensure alignment with quality requirements. Regular performance reviews and corrective action protocols help maintain supplier accountability and drive continuous improvement.

Supplier development programs support capability enhancement and technology transfer initiatives that benefit overall supply chain performance. Technical collaboration and knowledge sharing help suppliers optimize their processes while maintaining competitive positioning. Long-term partnership approaches foster stability and encourage investment in quality improvement initiatives.

Risk Management and Contingency Planning

Effective supply chain risk management requires identification of potential disruption sources and development of appropriate mitigation strategies. Natural disasters, equipment failures, and market volatility all pose threats to supply consistency that must be addressed through comprehensive contingency planning. Diversified supplier bases and strategic inventory management help maintain supply continuity during disruption events.

Regular risk assessments and scenario planning exercises help identify vulnerabilities and develop response protocols. Communication systems and emergency contact procedures ensure rapid coordination during crisis situations. Financial risk management tools, including supply contracts and insurance coverage, provide additional protection against supply disruption impacts.

FAQ

How does precursor fiber quality affect chopped carbon fiber consistency?

Precursor fiber quality directly impacts the mechanical properties, surface characteristics, and processing behavior of chopped carbon fiber. Variations in molecular weight distribution, spinning conditions, and stabilization parameters during precursor production can lead to inconsistencies in tensile strength, modulus values, and fiber-matrix adhesion properties. Maintaining strict quality control over precursor selection and processing parameters is essential for achieving consistent chopped fiber performance.

What role does chopping equipment maintenance play in product quality?

Regular maintenance of chopping equipment ensures consistent cutting performance and prevents quality degradation over time. Dull or misaligned cutting blades can cause fiber end damage, leading to reduced composite performance and inconsistent length distributions. Proper maintenance schedules, blade replacement protocols, and cutting parameter optimization help maintain product quality and minimize batch-to-batch variations in chopped carbon fiber characteristics.

How do storage and handling conditions impact chopped carbon fiber quality?

Storage and handling conditions significantly influence chopped carbon fiber quality through moisture absorption, contamination, and physical damage mechanisms. Humidity control prevents moisture-related processing issues, while proper packaging and handling procedures minimize fiber breakage and contamination. Temperature control during storage and transportation prevents thermal effects that could alter fiber properties or cause handling difficulties during downstream processing operations.

What testing methods are most effective for ensuring chopped carbon fiber consistency?

Effective quality control requires comprehensive testing protocols including tensile property evaluation, length distribution analysis, and surface quality assessment. Statistical process control methods help identify trends and variations before they impact customer applications. End-use application testing provides valuable feedback on real-world performance consistency, while correlation studies between process parameters and product properties enable optimization of manufacturing conditions for improved quality control.

Table of Contents

- Raw Material Quality and Sourcing Considerations

- Manufacturing Process Control and Equipment Considerations

- Storage and Handling Impact on Product Consistency

- Quality Control and Testing Methodologies

- Supply Chain Management and Vendor Relations

-

FAQ

- How does precursor fiber quality affect chopped carbon fiber consistency?

- What role does chopping equipment maintenance play in product quality?

- How do storage and handling conditions impact chopped carbon fiber quality?

- What testing methods are most effective for ensuring chopped carbon fiber consistency?