ההתפתחות של חומרים מתקדמים משולבים בעיצוב מודרני

עולמה של חומרי הרכבה עלה על נס עם הופעת טכנולוגיית סיבי פחמן מודForge . חומר חדשני זה יצר מחדש את מה שאפשרי בעיצוב אסתטי ופונקציונלי, ודחף קדימה גבולות שהוגדרו על ידי חיבורים מסיבי פחמןتقليדיים לפני עשורים. ככל שתעשיות שונות – מן האוטומובילים ועד לאווירspace – מחפצות אחר חומרים קלים יותר, חזקים יותר ונראים מובהקים יותר, סיבי פחמן מתוחמים צצים כחלופה מהפכנית שזוכה לבחינה מדוקדקת.

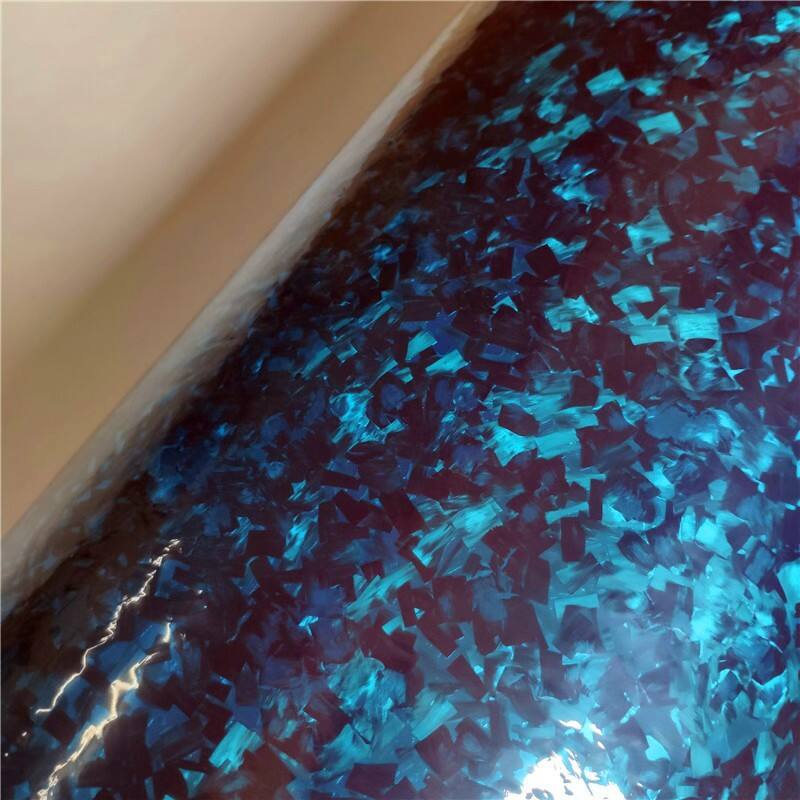

המראה המצופה השיש הייחודי והתכונות המכניות המעולות של סיבי פחמן מזויפים משכו את תשומת ליבם של מעצבים ומהנדסים כאחד. בניגוד לדפוסי האריגה הצפויים של סיבי פחמן מסורתיים, סיבי פחמן מזויפים מציגים אסתטיקה אורגנית ייחודית שהפכה מבוקשת יותר ויותר ביישומים יוקרתיים ובביצועים גבוהים. מוצרים .

תהליכי ייצור והבחנות טכניות

שיטות ייצור פיברגלאס קלאסיות

קומפוזיטי פיברגלאס טרדיציוניים מיוצרים בדרך כלל באמצעות תהליך של שיכבה, שבו ממקמים בזהירות דפים של פיברגלאס ארוג ומשחיזים אותם ברזין. התהליך המסודר הזה דורש יישור מדויק של הסיבים, ועשוי להימשך זמן רב. החומר שמתקבל מציג תכונות צפויות לאורך כיוון הסיבים, כאשר העוצמה והקשיחות נקבעות על פי דפוס האריגה וסדר השיכבות.

שיטת הייצור הקונבנציונלית כוללת מספר שלבים: אריג סיבים, יצירת פריפרג', עיצוב שיכבה ולבסוף עיבוד גמר. אף שהתהליך הזה שופר לאורך עשורים, עדיין קיימות מגבלות מבחינת מהירות ייצור ועושר גאומטרי.

חדשנות בתהליך ייצור סיבי פחמן מתוחמים

לעומת זאת, פיברגלאס מתוכנן משתמש בטכניקת ייצור מהפכנית בה חוטי סיבים קצרים ממוזגים עם רזין ומדוחסים תחת לחץ וטמפרטורה גבוהים. תהליך זה, הידוע בשם יציקה בלחיצה, יוצר אוריינטציה אקראית של הסיבים שתרומה לתכונות איזוטרופיות יותר. זמן הייצור מופחת בצורה משמעותית, וקצר לרוב למספר דקות לעומת שעות או ימים בחומרי גלם מסורתיים.

תהליך היציקה בלחיצה מאפשר צורות מורכבות וגאומטריות שיאושרו כקשות או בלתי אפשריות עם פיברגלאס מסורתי. גמישות הייצור הזו פתחה אפשרויות חדשות בעיצוב ו שימוש במגוון תעשיות.

מאפייני ביצועים ותכונות החומר

שלמות מבנית וניתוח חוזק

בעוד בוחנים את הביצועים המבניים, פיברגלאס מוכתך מציג מאפיינים ייחודיים שغالבהן עולין על חומרי הרכיבה המסונפנים. האוריינטציה האקראית של הסיבים יוצרת התפלגות אחידה יותר של הכוחות בכל חומר, מה שמוביל להתנגדות מ удар טובה יותר ופחת בסיכון להתקלפות. החומר מציג חוזק דחיסה מעולה ומסוגל לעמוד בתרחישי עומס מורכבים בצורה יעילה.

בדיקות הראו שרכיבים מפיברגלאס מוכתך יכולים להשיג עד 20% עוצמה סגולית גבוהה יותר ביישומים מסוימים, תוך שמירה על עמידות דומה או טובה יותר בפני עייפות בהשוואה לחומרי פיברגלאס מסורתיים. תצורת הביצועים המשופרת הזו הופכת אותם למשיכים במיוחד ליישומים של מתח גבוה.

שקולות משקל וצפיפות

אחת מהיתרונות החשובים ביותר של פיברגלאס מתכתי היא הפוטנציאל לצמצום משקל תוך שמירה על שלמות המבנית. תהליך הזרקה תחת לחץ מאפשר שבריר נפח סיבים אופטימלי ותכולה מינימלית של חללים, מה שיוצר רכיבים שיכולים להיות עד 15% קלים יותר מקולגותיהם מסיבי פחמן טרדיציוניים.

ניתן לשלוט בצורה מדויקת בצפיפות החומר במהלך הייצור, מהמאפשר לעצבי תכניות ליצור חלקים עם תכונות משתנות בתוך אותו רכיב. גמישות זו בשליטת הצפיפות מציעה אפשרויות חדשות לאופטימיזציה של התפלגות המשקל והתכונות המכניות.

יישומי עיצוב והיבטים אסתטיים

מראה חזותי וסיום פני השטח

האסתטיקה הייחודית של פיברגלאס מודגש יוצרת חוסר בשוק העיצוב. הדפוסים המורכבים והאורגניים שלו יוצרים חותם חזותי ייחודי שמעצבי תעשייה וצרכנים רבים מוצאים אותו אטרקטיבי יותר מהדפוסים הקשיחים של פיברגלאס קונבנציונלי. השונות הטבעית במראה הופכת כל פריט לייחודי במהותו, מה שמגדיל את ערכו ביישומים של יוקרה והתאמה אישית.

אפשרויות גימור פני השטח של פיברגלאס מודגש הן רבות-משמעיות יותר, שכן ניתן להבריק, לטקסטיר או לשלב את החומר עם חומרים אחרים בקלות רבה יותר בהשוואה לקומפוזיטים מסורתיים. הפיזור האקראי של הסיבים מבטל את הצורך לקחת בחשבון את כיוון הת weave בחלקים גלויים, מה שמקל על תהליך העיצוב.

חופש בעיצוב וגמישות בייצור

תהליך הזרקת דחיסה המשמש בייצור פיברגלס מודפס מאפשר חופש עיצוב גדול בהשוואה לשיטות שכבתיות מסורתיות. ניתן להשיג גאומטריות מורכבות, זוויות חדים ופרטים מתוחכמים בפעולת ייצור אחת, מה שמפחית את דרישות ההרכבה ומשפר את החוזק המבני.

גמישות הייצור הזו אפשרה לעיצובים ליצור פתרונות חדשניים בתעשיות שונות, החל מרכיבי רכב ועד לאלקטרוניקה לצרכן. היכולת לייצר צורות מורכבות בצורה יעילה תרמה גם להנחות עלות בApplications מסוימות, במיוחד בסצnenarios של ייצור בכמויות בינוניות עד גבוהות.

מגמות עתידיות ויישומים תעשייתיים

טכנולוגיות חדשות וחדשנות

פיתוח טכנולוגיית הפיברגלאס המודרסת ממשיך להתקדם, עם חדשנות חדשה בתחומי תהליכי הייצור ונוסחאות החומרים. המחקר נמשך לחומרים היברידיים שמשלבים פיברגלאס מודרסת עם חומרים מרוכבים או מתכות אחרים, ויוצרים אפשרויות חדשות לאופטימיזציה של מאפייני ביצועים.

תהליכי ייצור אוטומטיים וכלים מתקדמים לדימות עושים את ייצור הפיברגלאס המודרסת יעיל וצפו יותר. צפוי שההתפתחות הזו תקדם אימוץ רחב יותר בין התעשיות ותאפשר יישומים חדשים שעד כה נחשבו לא מעשיים עם חומרים מרוכבים מסורתיים.

תקינות ותפוקה סביבתית

ההשלכות הסביבתיות של ייצור פיברגלאס מתכתי חשובות באופן גובר בהחלטות בחירת חומרים. זמן עיבוד קצר יותר ופסולת מופחתת בהשוואה לייצור פיברגלאס מסורתי יכולים להוביל להשפעה סביבתית כוללת נמוכה יותר. בנוסף, מחקר ברזינתי ניתנים לחזרה בשימוש וממקורות סיבים בר-קייימא הופך את החומר ליותר ידידותי לסביבה

ההתפתחות העתידית בתחום זה תתמקד ככל הנראה בשיפור הפוטנציאל של החומר להחזרה בסוף מחזור החיים שלו ובהפחתת עוצמת האנרגיה בתהליך הייצור, מה שעושה מהפיברגלאס המתכתי בחירה ברת קיימא יותר ליישומים מודרניים

שאלות נפוצות

מה גורם לפיברגלאס מודForge להיות שונה מסיבי פחמן מסורתיים?

סיבי פחמן מודרסיים משתמשים בתהליך עיבוד של דפוס קומפרסיה עם חוטי סיבים חתוכים, מה שמייצר אוריינטציה אקראית של הסיבים ודפוסים אסתטיים ייחודיים. זה שונה מבניית הפחמן המסורתי השזור, ומייצר תכונות איזוטרופיות יותר וזמני ייצור קצרים יותר.

איך עלות סיבי הפחמן המודרסיים משתווה לחומרים מרוכבים מסורתיים?

בעוד עלות הכלים הראשונית עבור סיבי פחמן מודרסיים עשויה להיות גבוהה יותר, זמני הייצור הקצרים יותר ודרישות העבודה הנמוכות יותר לרוב מייצרים עלות כוללת נמוכה יותר בשרשראות ייצור בינוניות ועד גדולות בהשוואה לחומרים מרוכבים מסורתיים של פחמן.

האם ניתן לתקן סיבי פחמן מודרסיים כמו סיבי פחמן מסורתיים?

ניתן לתקן רכיבי פיברגלאס מודForge, אם כי התהליך שונה מתיקון פיברגלאס קלאסי. האוריינטציה האקראית של הסיבים הופכת את התיקונים המקומיים לפחות נראים, כיוון שאין צורך להתאים דגמי ארוג מסוימים. עם זאת, התיקונים תמיד צריכים להתבצע על ידי טכנאים מוסמכים תוך שימוש בחומרים ושיטות מתאימים.