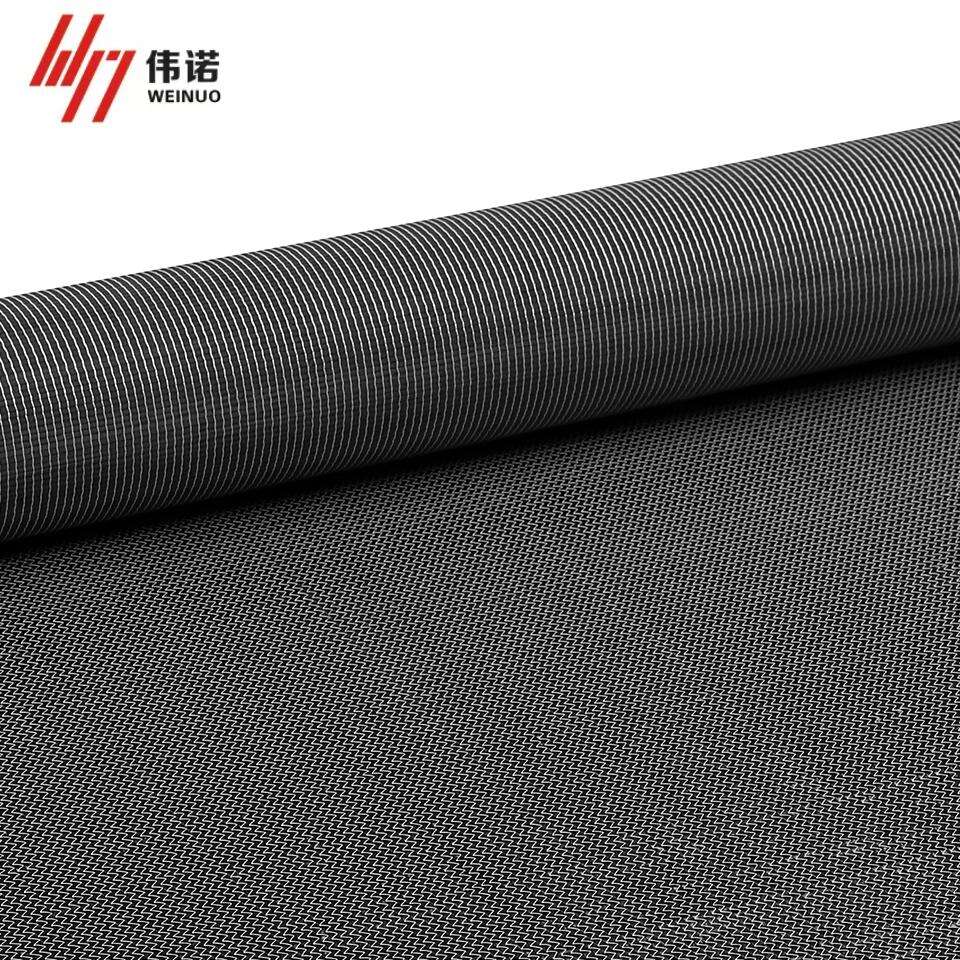

kevlar carbon fabric

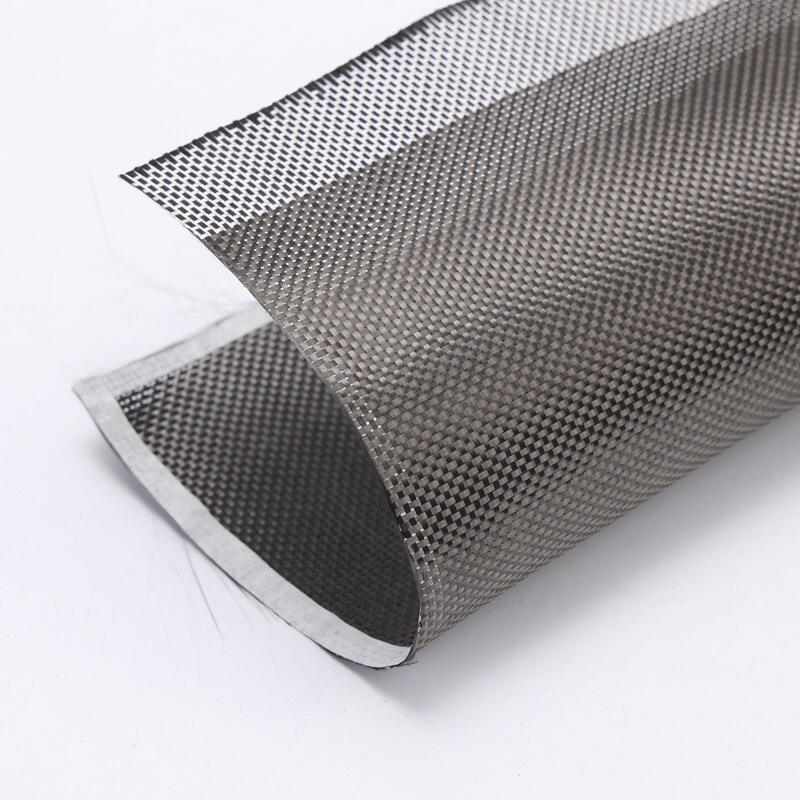

Kevlar carbon fabric represents a revolutionary composite material that combines the exceptional strength of Kevlar fibers with the lightweight properties of carbon fiber. This innovative hybrid material delivers outstanding mechanical performance while maintaining minimal weight characteristics. The fabric consists of interwoven Kevlar and carbon fibers, creating a unique structure that maximizes the benefits of both materials. Kevlar provides superior impact resistance and tensile strength, while carbon fiber contributes exceptional stiffness and thermal stability. This combination results in a versatile material widely used in aerospace, automotive, and protective equipment industries. The fabric's distinctive yellow-black appearance comes from the natural color of Kevlar fibers interwoven with black carbon strands. Manufacturing involves a precise weaving process that ensures optimal fiber orientation for maximum strength. The material exhibits remarkable resistance to environmental factors, including UV radiation and chemical exposure, making it suitable for both indoor and outdoor applications. Engineers and designers particularly value this fabric for its ability to maintain structural integrity under extreme conditions while offering significant weight savings compared to traditional materials. The fabric can be customized in various weave patterns and thicknesses to meet specific application requirements, from lightweight sports equipment to heavy-duty protective gear.