Rruga e Changjiang Mingzhu nr. 80, Lagja Houcheng, Qyteti i Zhangjiagang, Provinca Jiangsu, Kina +86-15995540423 [email protected] +86 15995540423

Materiat e shumëakse prej karboni përdoren gjerësisht në shumë fusha si aero-hapësirorja, prodhimi i energjisë nga era, prodhimi i automjeteve, transporti hekurudhor, pajisje sportive, fortesimi i ndërtesave dhe pajisje mjekësore për shkak të pesha të vogël, fortësisë së lartë dhe vetive mekanike të shkelqyera shumëdrejtime, kryesisht të përdorura për prodhimin e pjesëve strukturore të lehta por me performancë të lartë për të përmirësuar qëndrueshmërinë dhe efikasitetin e pRODUKTET , dhe në të njëjtën kohë, me zhvillimin e teknologjisë dhe rritjen e nevojave për mbrojtje të ambientit, gjithashtu, me zhvillimin e teknologjisë dhe rritjen e kërkesës për mbrojtje të ambientit, zona e saj aplikimi po zgjerohet ende.

Koncepti bazë i materies shumëakse

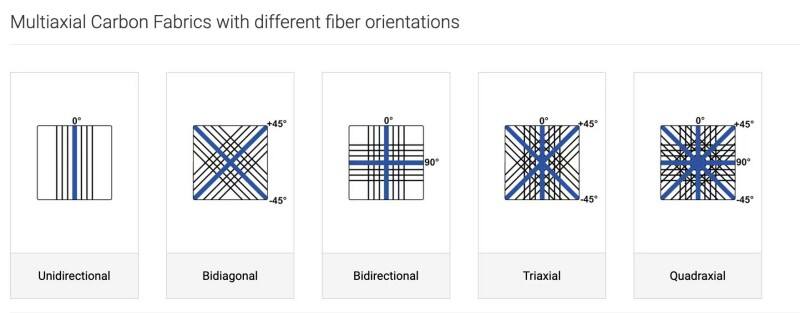

1. Fibra e karbonit multiaxiale i referohet një strukture në të cilën fibrat e karbonit janë të rregulluara në shtresa në shumë drejtime ose drejtime aksiale në një kompozit fibër karboni. Kjo strukturë mund të arrijë fortësi dhe ngurtësi kundër shumë drejtimeve, duke përmirësuar kështu performancën e përgjithshme të materialit kompozit.

2. Peshqirët e fibrës së karbonit multiaxialë janë peshqira të bëra prej filave të fibrës së karbonit që janë të rrëmbyer me basma poliestere përmes këndeve shumë-drejtimore 0°/+45°/-45°/90°.

| 0/90° | ±45° |

|

|

Peshqiri i fibrës së karbonit multiaxial përdor një strukturë shtresash me kënd shumëfishe 0°, ±45°, 90°, etj., dhe arrin pozicionimin e saktë përmes teknologjisë së rrëmbjes së varkës. Çdo shtresë fibërsh është e vendosur në një kënd specifik për të formuar një strukturë biomimike të ngjashme me skeletin biologjik. Kjo dizajnim i veçantë i lejon materialit të ruajë fortësinë e lartë në drejtime të ndryshme të tensionit, duke kapërcyer defektet e peshqirave tradicionale një-drejtimore me anizotropi të dukshme.

Peshqir i Ftohur VS. Peshqir Multi-Axial

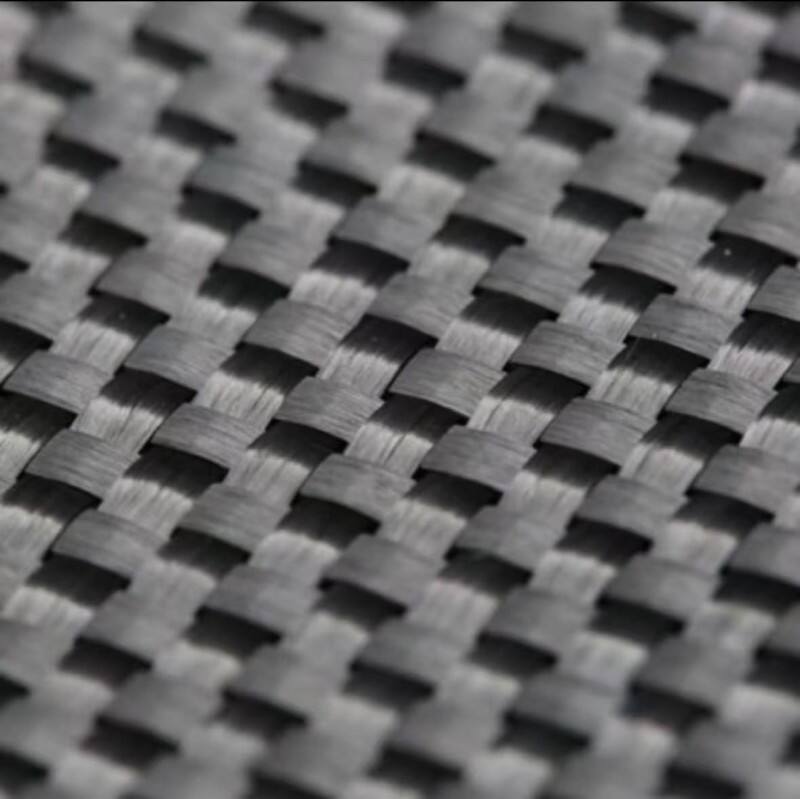

【PLAIN】

(1) Stabilitet i tepruar: Për shkak të distancës së shkurtër midis pikave të ndërprerë, qepset me prerje të thjeshtë kanë një shkallë të lartë stabiliteti, gjë që i bën të papërshtatshme për përdorim në mbulesa me profile komplekse, pasi nuk janë kaq të fleksibël si disa qepse të tjera.

(2) Përqendrimi i tensionit: Për shkak të kryqëzimit të tepërt (këndi i formuar nga fibrat gjatë pembitjes) në telash, kryqëzimi i rough krijon një përqendrim tensioni që mund të dobësojë pjesën me kalimin e kohës

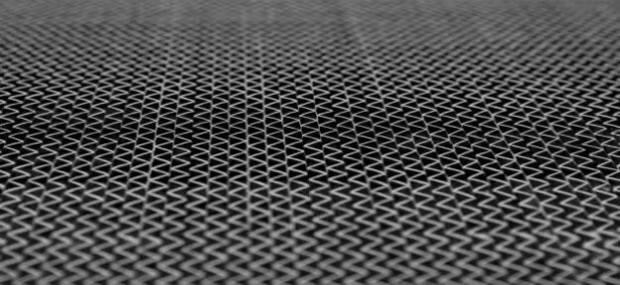

【TWILL】

(1)Ekuilibri i fleksibilitetit dhe stabilitetit: Qepset twill nuk janë aq të mira sa qepset e thjeshta megjithëse kanë fleksibilitet të mirë dhe mund të formojnë konture komplekse.

(2)Ndryshimi i fortësisë: Qepset twill janë më pak të forta se qepset e thjeshta, gjë që mund të ndikojë në përdorimin e tyre në disa aplikime që kërkojnë fortësi të lartë tërheqëse.

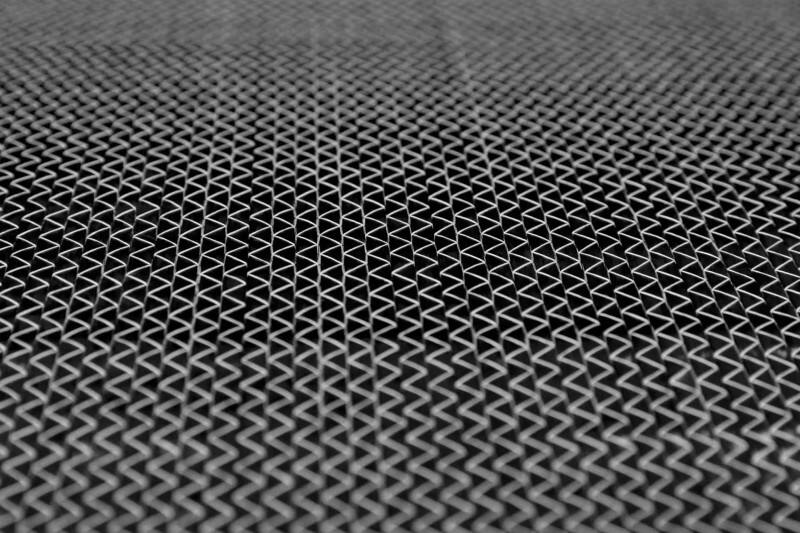

【Multi-Aksial Qendra】

Në kundërshtim me qendrat tradicionale të pemës:

(1)Fortësi dhe ngurtësi shumëkahe: ctional strength and stiffness: Kjo është një përmirësim i rëndësishëm për pëlhurat e thjeshta, të cilat nuk janë të përshtatshme për laminime komplekse të konturit për shkak të stabilitetit të tepërt.

(2)Rritja e shtrembërimit të fibrave: Bërja e thjerrëzimit rrit shumë forcën e prerjes ndërlaminar, tolerancën ndaj dëmtimit, forcën e goditjes dhe vetitë e kompresimit pas goditjes së kompozitëve, e cila është më e favorshme për forcën e fibrave.

Fushat e aplikimit për pëlhura shumëaksiale

aero-hapësinore:T f22 dhe udhëtimi „e hollë“ i Boeing 787】

Në krahët e aeroplanit, kuadrot strukturorë dhe pjesë të tjera, kërkohen materiale që janë njëkohësisht të lehtë dhe me veti mekanike shumë-drejcionëse për të rezistuar ngarkesave ajroaerodinamike dhe stresit shumëdimensional. Përdorimi i qepave multi-aksi të fibër karboni nëpërmjet një dizajni të arsyeshëm të vendosjes së fibrave bën që struktura e pjesës të jetë më e qëndrueshme, me forcë dhe ngurtësi të rritur

Trupi i Boeing 787, fletët e ventilatorit, etj., qepja multi-aksiale e fibër karboni zvogëlon në mënyrë të konsiderueshme peshën dhe rrit qëndrueshmërinë ndaj stresit në shumë drejtime, gjë që materiali tradicional i fibër karboni nuk mund ta përballojë efektivisht dhe që shpesh çon në tharje të vazhdueshme

【Transporti hekurudhor: CETROVO, gjenerata e re e mjeteve metropolitane me fibër karboni nga CSR Qingdao Sifang Rolling Stock Co.】

Trup më i lehtë, funksionim më i efikshëm në përdorimin e energjisë. Peshën e trupit të metronit prej fibër karboni e zvogloni me 25%, kuadri i rrotave (kuadër me shumë boshte prej fibër karboni) e ka peshën e zvogëluar me 50%, peshën totale të veturës e zvogloni rreth 11%, konsumin e energjisë gjatë funksionimit me 7%, çdo tren mund të reduktojë emetimet e dioksidit të karbonit rreth 130 tonë në vit, që është ekuivalent me 101 akra pylltizim.

Kosto më të ulëta të mirëmbajtjes gjatë ciklit të jetës. Falë materialeve të vogla nga fibra karboni dhe aplikimit të teknologjive të reja, fërkimi i rrotës dhe binarit të trenit të metros me fibër karboni është zvogëluar ndjeshëm, duke ulur kështu sasinhtë e mirëmbajtjes së veturës dhe binarit, duke zvogëluar kostot e mirëmbajtjes gjatë ciklit të jetës me 22%.

【Industria ushtarake: Armë e fshehtë e avionit luftarak amerikan F22-Raptor】

Avioni luftarak i SHBA-së F-22 "Raptor" përmes përdorimit të një varieteti të materialeve kompozite të forcuara me fibra karboni, duke përfshirë materiale kompozite prej fijeje karboni me ndërtim shumëbosht me prerje, ka arritur që përqindja e përdorimit të këtyre materialeve në pjesët kryesore si krahët, bishtin e pasëm, bishtin horizontal, dhe mbulesën e trupit të jetë aq e lartë sa 35%, duke ulur në mënyrë të konsiderueshme peshën e trupit të avionit, duke përmirësuar fleksibilitetin manovrier, si dhe vetitë kundër lodhjes dhe korrozionit. Pesha e trupit është zvogëluar në mënyrë të konsiderueshme, ndërsa manovrimi, rezistenca ndaj lodhjes dhe korrozionit janë përmirësuar.

【Sektori civil: Revolucioni i Materialeve të Gjeneratës së Re】

Në fushën civile, stofat shumëboshtore prej fibër karboni janë përdorur gjerësisht në shumë industri si ndërtimi, kujdesja mjekësore, transporti dhe pajisjet sportive, dhe produktet e tyre janë integruar thellësisht në jetën e përditshme. Në fushën e ndërtimit, materiali është adoptuar gjerësisht për riparimin dhe forcimin e strukturave inxhinierike ekzistuese për shkak të avantazheve të tij të konstruksionit të lehtë dhe efektit të besueshëm, gjë që ka nxitur në mënyrë të konsiderueshme zgjerimin e aplikimit të tij në industrinë e ndërtimit. Në fushën mjekësore, me zhvillimin e teknologjisë mjekësore dhe përmirësimin e vetëdijes së shëndetit, kërkesa e tregut për pajisje mjekësore me performancë të lartë vazhdon të rritet, dhe funksionimi i pajisjeve në ngarkesë të lartë paraqet kërkesa të ashpra për qëndrueshmërinë e tyre. Materialët prej fibër karboni kanë treguar se posedojnë inertesie kimike të shkëlqyeshme (rezistencë ndaj korrozionit, acidit dhe alkalive) dhe stabilitet dimensional, duke bërë që ata të jenë një zgjedhje ideale materiale për prodhimin e pajisjeve mjekësore. Mjetet e transportit përfitojnë nga karakteristikat e lehta dhe të forta të stofave shumëboshtore (rezistencë e shkëlqyer ndaj terheqjes dhe prerjes), të cilat zvogëlojnë në mënyrë të konsiderueshme peshën e pavetë të karrocerisë dhe ulin konsumin e energjisë, ndërkohë që vetitë e shkëlqyera mekanike përmirësojnë efikasisht sigurinë pasive të mjetit. Në industrinë e pajisjeve sportive, kompozitet e fibër karboni plotësojnë kërkesën e konsumatorëve për pajisje me performancë të lartë dhe garantojnë cilësinë dhe qëndrueshmërinë e produktit me peshën e tyre të lehtë, zhvorësinë e lartë, rezistencën e shkëlqyer ndaj lodhjes dhe karakteristikat me deformim të ulët.

Perspektiva për të ardhmen

Me përmirësimin e vazhdueshëm të kërkesës për aplikimin e materialeve kompozite, stofrat shumëboshtë prej fibër karboni do të hyjnë në një hapësirë më të gjerë zhvillimi në shumë fusha, falë këndit të personalizuar të vendosjes, lirisë së lartë projektuese dhe vetive mekanike të shkëlqyera. Në të ardhmen, me përparimin e teknologjisë së prodhimit automatik dhe i sistemeve të reja të rësinës, efikasiteti i prodhimit të stofrave shumëboshtë do të përmirësohet më tej, kostoja do të vazhdojë të optimizohet dhe do të promovohet aplikimi i tij në masë në fusha të larta si palete turbinash erë, automjete energjie të reja, ajrohapesirë dhe të tjera. Në të njëjtën kohë, rezistenca e shkëlqyeshme ndaj goditjeve dhe vetia anti-lodhje të stofit shumëboshtë do të luajnë një vlerë edhe më të madhe në fushën civile të forcimit të ndërtesave, pajisjeve sportive dhe pajisjeve mjekësore, duke kontribuar në përhapjen e produkteve të lehta dhe me performancë të lartë.

Të drejtat e rezervuara © 2026 Zhangjiagang Weinuo Composites Co., Ltd.