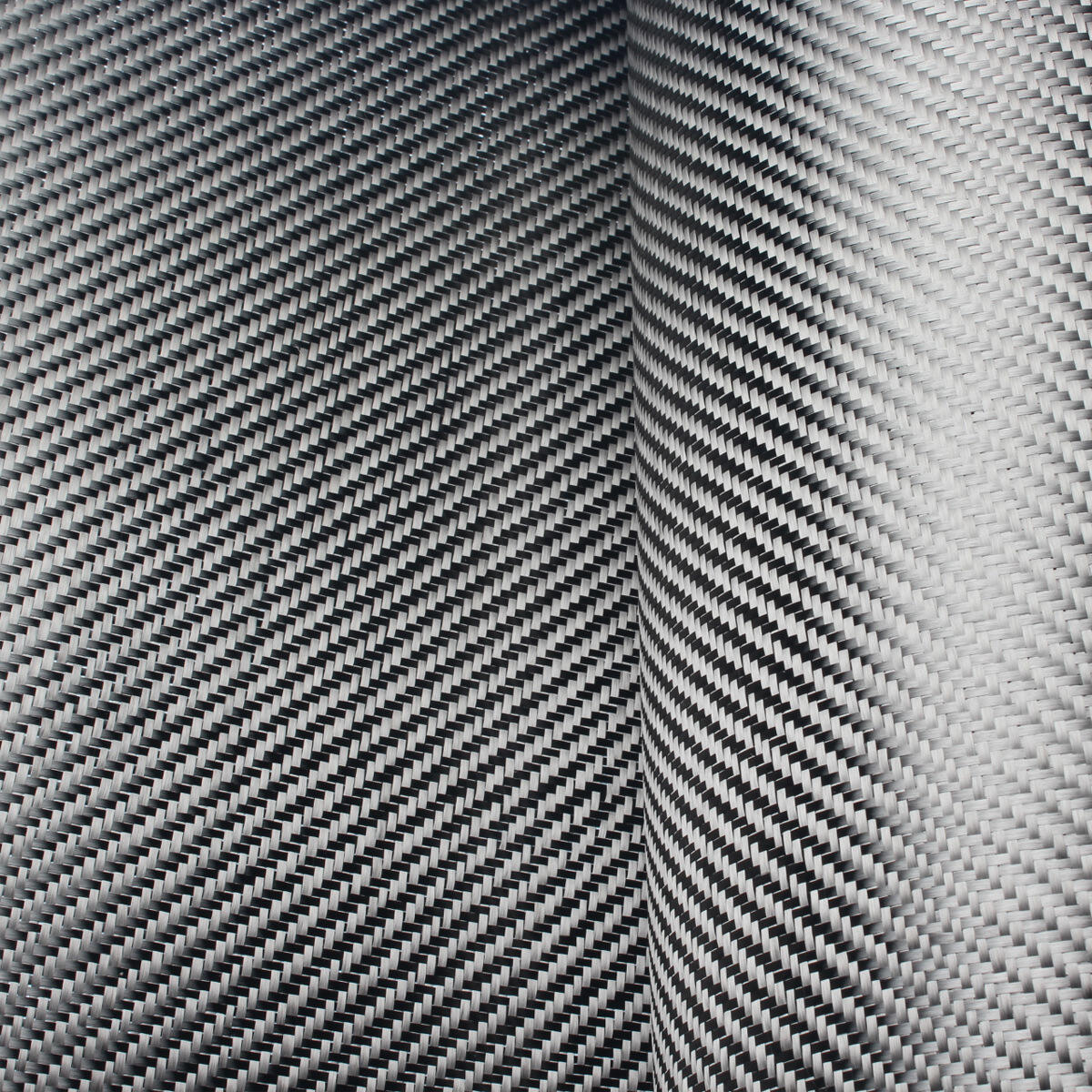

4x4 twill carbon fiber fabric

4x4 twill carbon fiber fabric represents a sophisticated textile engineered for superior performance and durability. This advanced material features a distinctive weave pattern where each carbon fiber strand passes over four strands before going under four strands, creating a balanced and symmetrical diagonal pattern. This specific construction method results in a material that offers exceptional strength-to-weight ratios while maintaining flexibility and handling characteristics. The fabric's unique structure provides enhanced draping capabilities, making it ideal for complex geometric shapes and curved surfaces. With a typical weight range of 3K to 12K, this fabric delivers consistent performance across various applications. The material exhibits outstanding resistance to temperature variations, chemical exposure, and mechanical stress, making it a premier choice for high-performance applications. Its balanced weave pattern ensures uniform strength distribution in both warp and weft directions, while the surface texture provides an aesthetically pleasing appearance that's particularly valued in visible applications. The fabric's structure allows for optimal resin penetration during composite manufacturing, ensuring thorough wet-out and strong interlaminar bonds.