buy twill weave carbon fiber

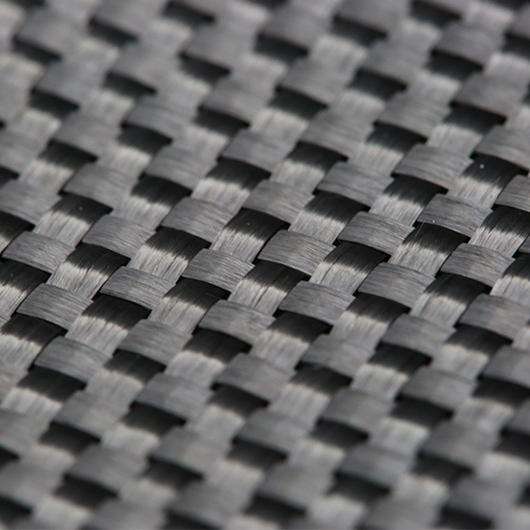

Twill weave carbon fiber represents a sophisticated advancement in composite materials, characterized by its distinctive diagonal pattern created through the weaving process. This premium material consists of carbon fiber tows woven in a repeated pattern where each warp fiber passes over two or more weft fibers. The resulting 2x2 twill pattern creates a smoother, more aesthetically pleasing surface compared to plain weave carbon fiber. When purchasing twill weave carbon fiber, customers gain access to a material that offers exceptional strength-to-weight ratios, superior flexibility, and enhanced draping capabilities. The material's unique weave pattern distributes stress more evenly across the fabric, making it ideal for complex curved surfaces and demanding applications. Available in various weights and widths, twill weave carbon fiber can be purchased in both dry fabric form and pre-impregnated with resin systems. This versatility makes it suitable for automotive components, aerospace applications, sporting goods, and high-end consumer products. The material's distinctive appearance, combined with its structural properties, has made it increasingly popular in both functional and decorative applications.