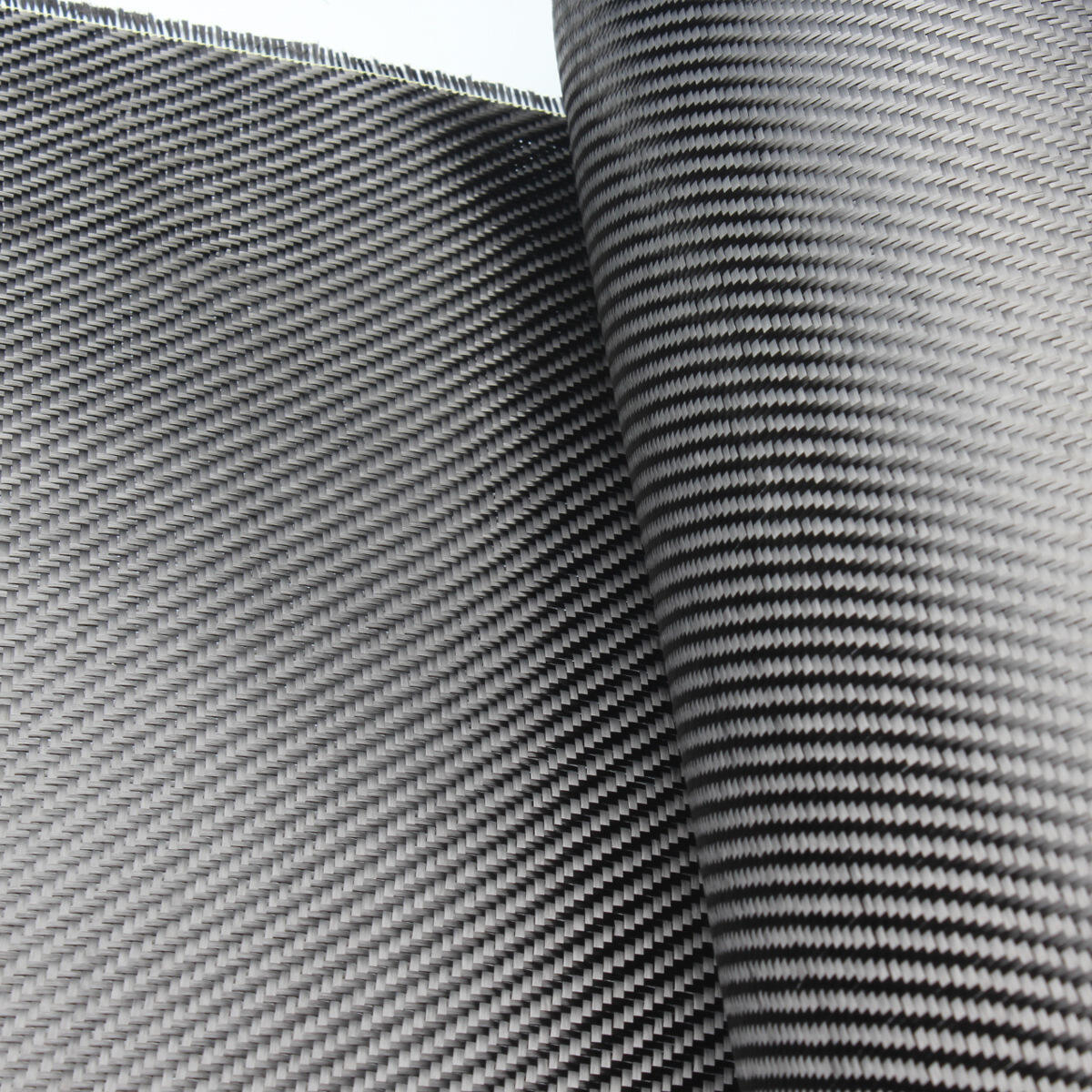

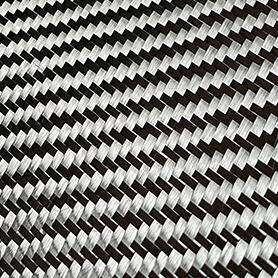

custom twill weave carbon fiber fabric

Custom twill weave carbon fiber fabric represents a pinnacle achievement in advanced composite materials, offering an exceptional combination of strength, durability, and aesthetic appeal. This specialized material features carbon fiber tows woven in a distinctive 2x2 pattern, creating a characteristic diagonal rib on the surface that provides both structural integrity and visual distinction. The customization aspect allows manufacturers to specify various parameters including fiber weight, weave density, and surface finish to meet specific application requirements. The fabric's inherent properties include superior tensile strength, remarkable resistance to fatigue, and excellent dimensional stability across diverse environmental conditions. Its lightweight nature, typically 40% lighter than aluminum while offering five times the strength, makes it an ideal choice for applications where weight reduction is crucial. The material's versatility extends to its finishing options, with the ability to be treated with different resins and coating systems to enhance specific performance characteristics. In industrial applications, this fabric excels in producing high-performance components for aerospace, automotive, and marine sectors, while also finding increasing use in consumer products where premium quality and performance are paramount. The material's adaptability to various forming processes, including autoclave curing, vacuum bagging, and compression molding, further enhances its manufacturing versatility.