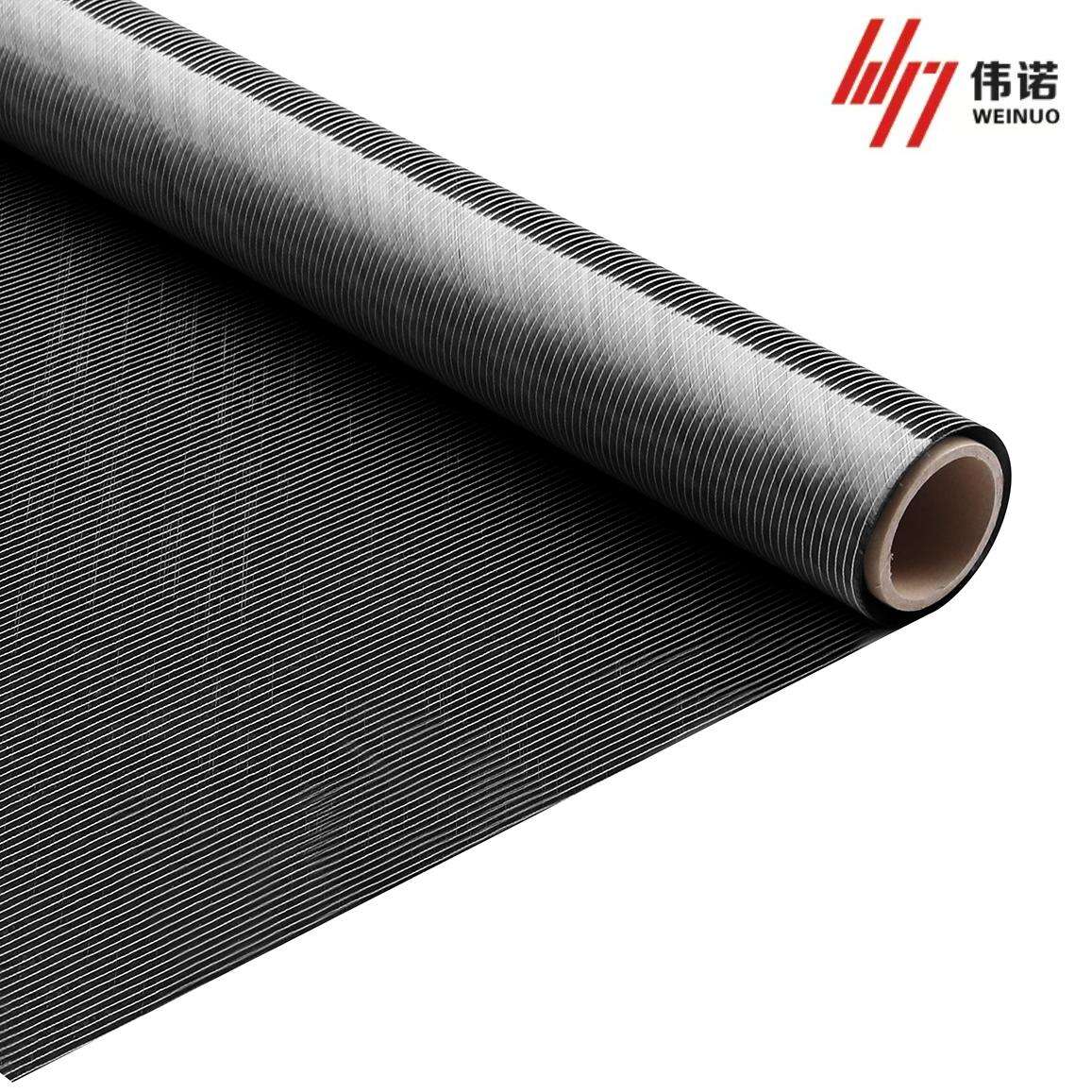

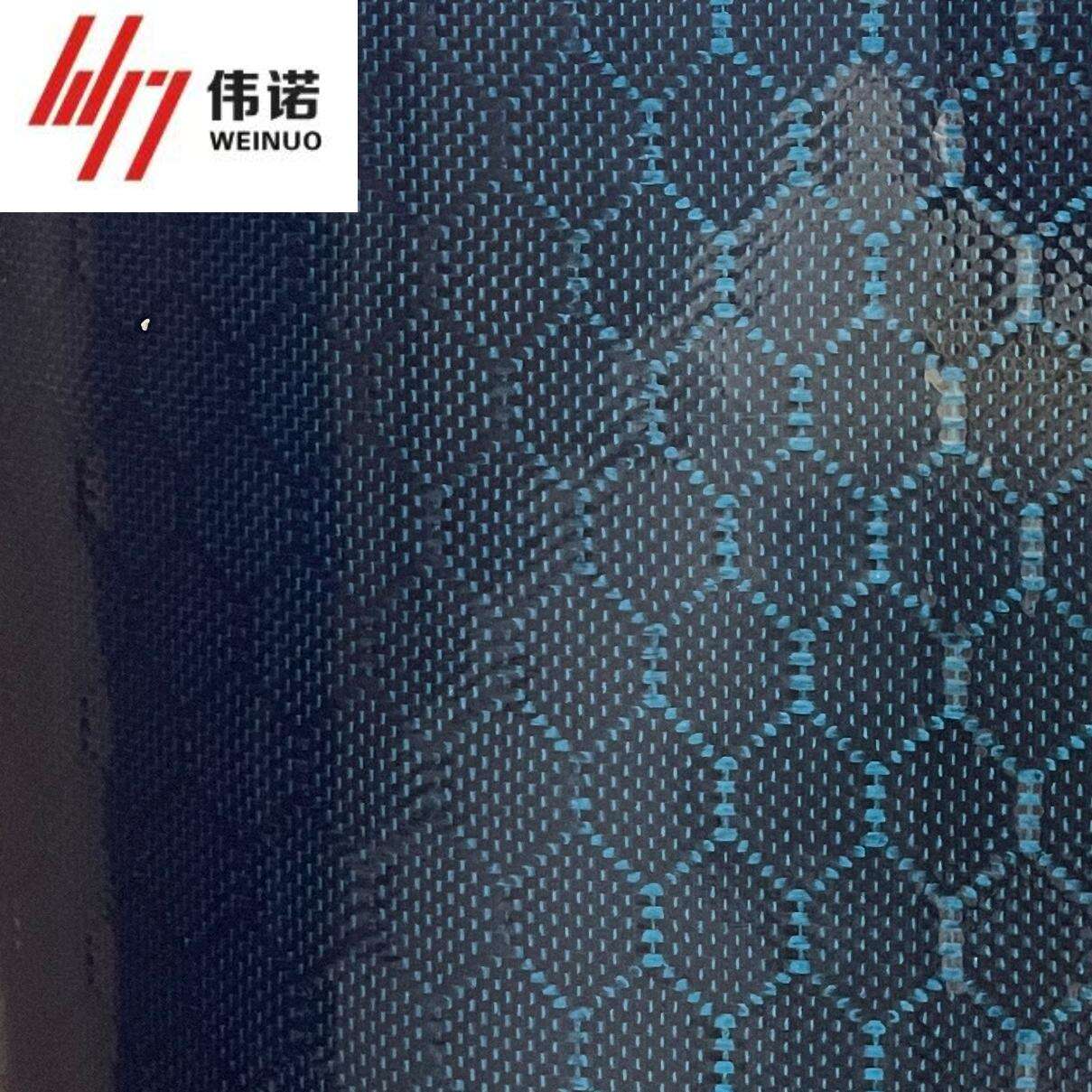

prepreg carbon fiber roll

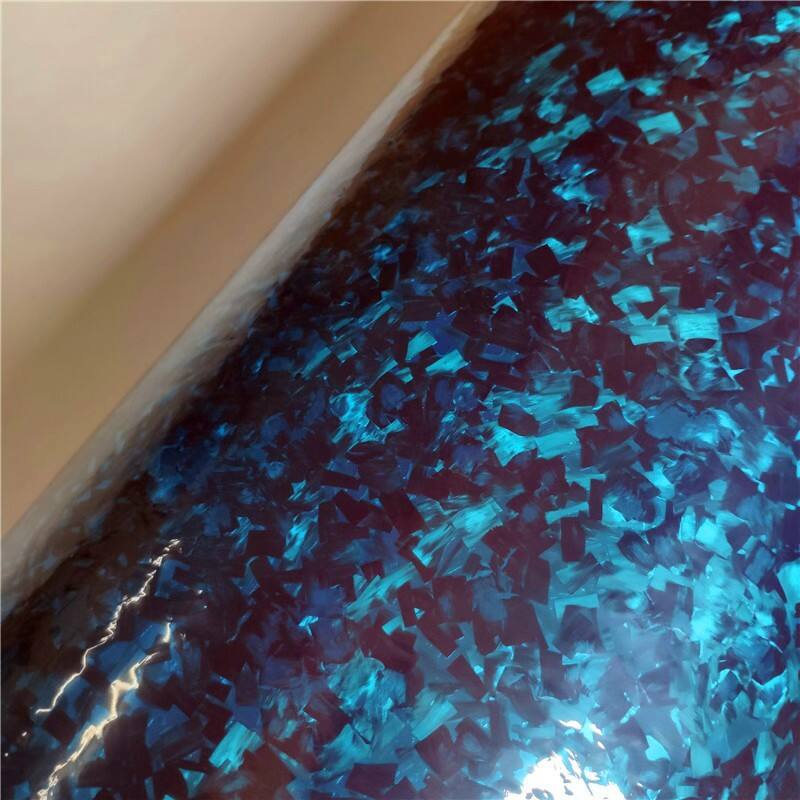

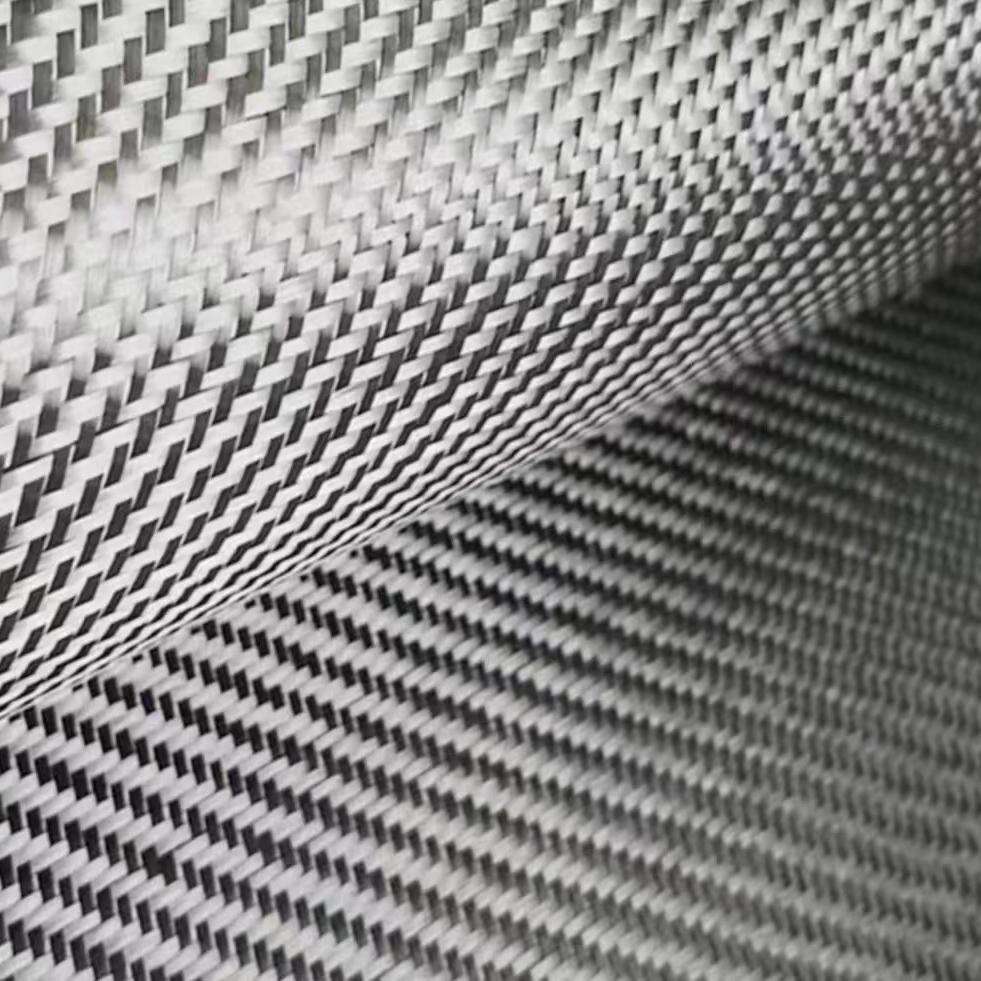

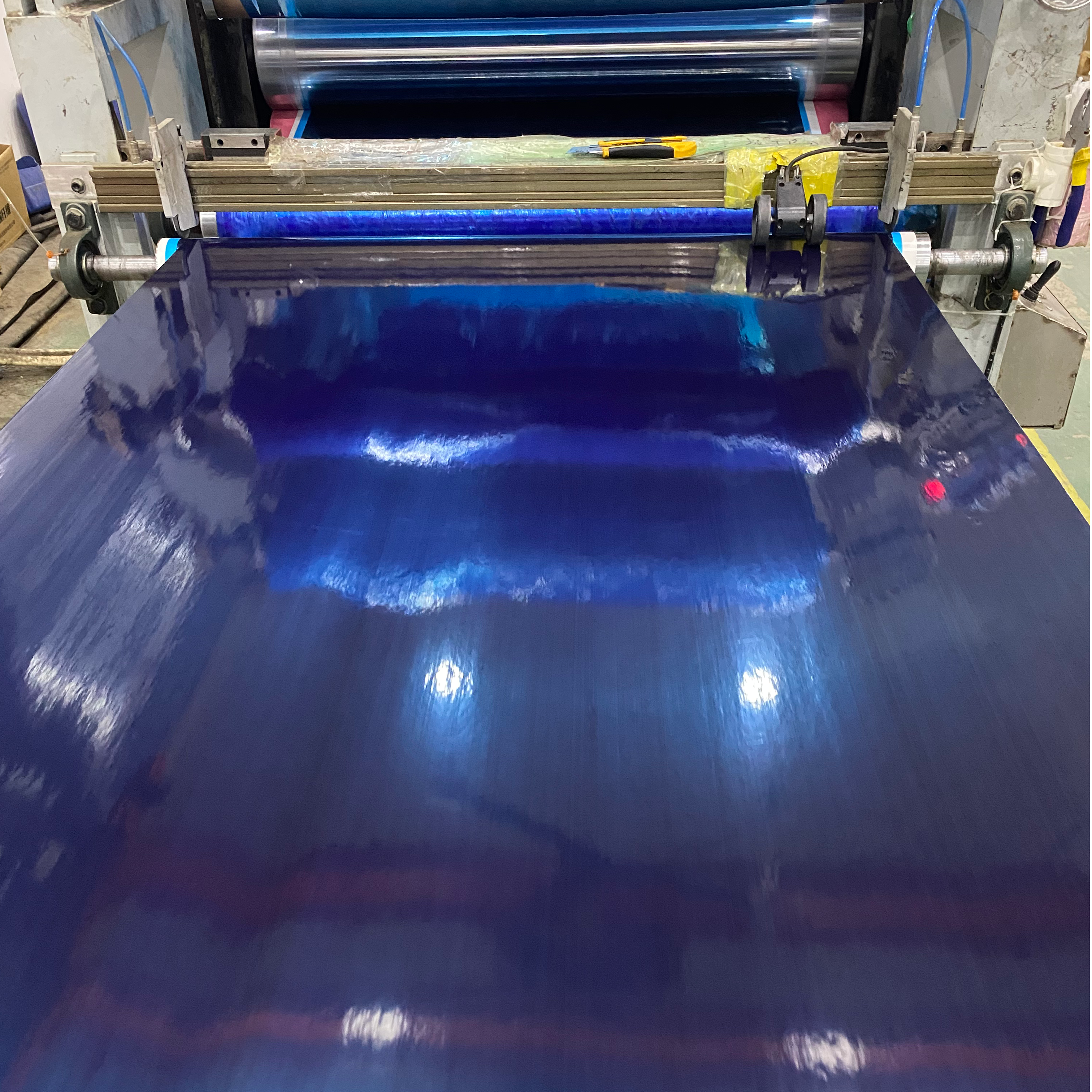

Prepreg carbon fiber rolls represent a significant advancement in composite materials technology, offering a pre-impregnated combination of carbon fiber reinforcement and matrix resin systems. These specialized materials are manufactured under precisely controlled conditions, where high-quality carbon fibers are carefully impregnated with a precise amount of resin matrix. The resulting material is partially cured and delivered in roll form, maintaining a specific fiber-to-resin ratio that ensures optimal performance. These rolls are stored in temperature-controlled environments to prevent premature curing and typically require refrigeration to maintain their shelf life. The material offers exceptional strength-to-weight ratios, consistent quality, and reliable performance across various applications. When heated and pressed during the final manufacturing process, the resin flows and cures, creating an extremely strong, lightweight composite structure. The controlled resin content eliminates the variability and mess associated with wet layup processes, while also ensuring uniform material properties throughout the finished product. These rolls find extensive use in aerospace, automotive, sporting goods, and industrial applications where high performance and reliability are paramount.