prepreg carbon fiber suppliers

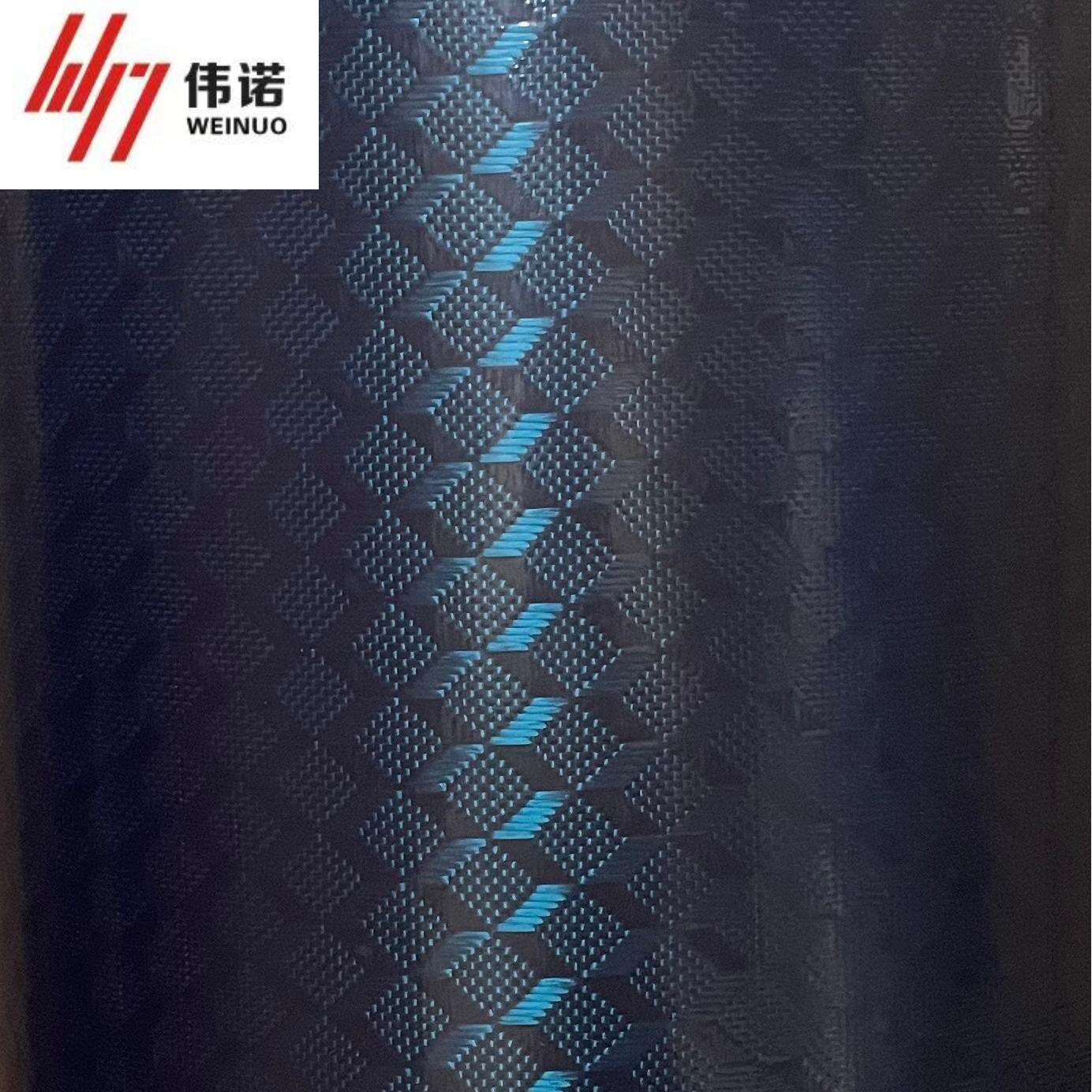

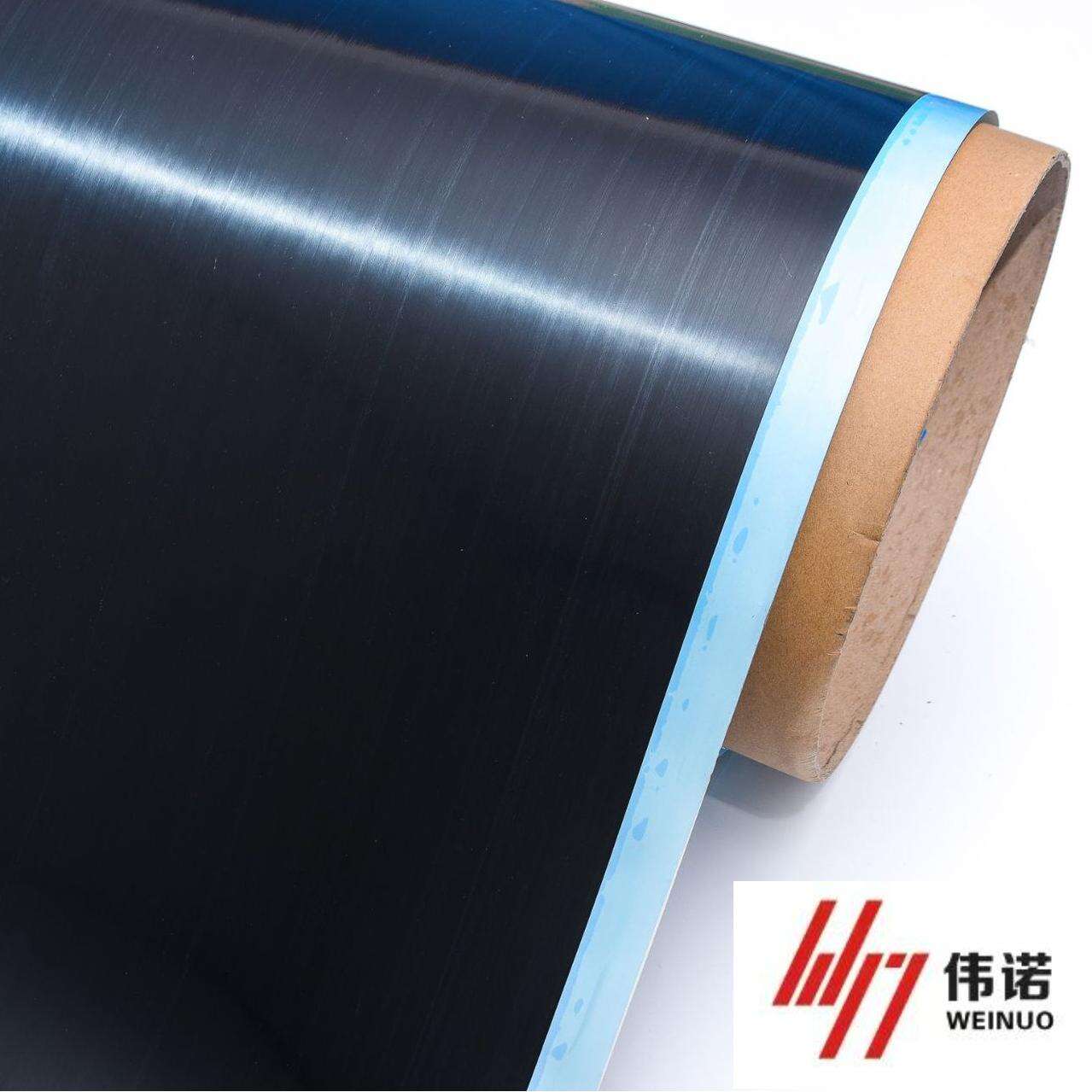

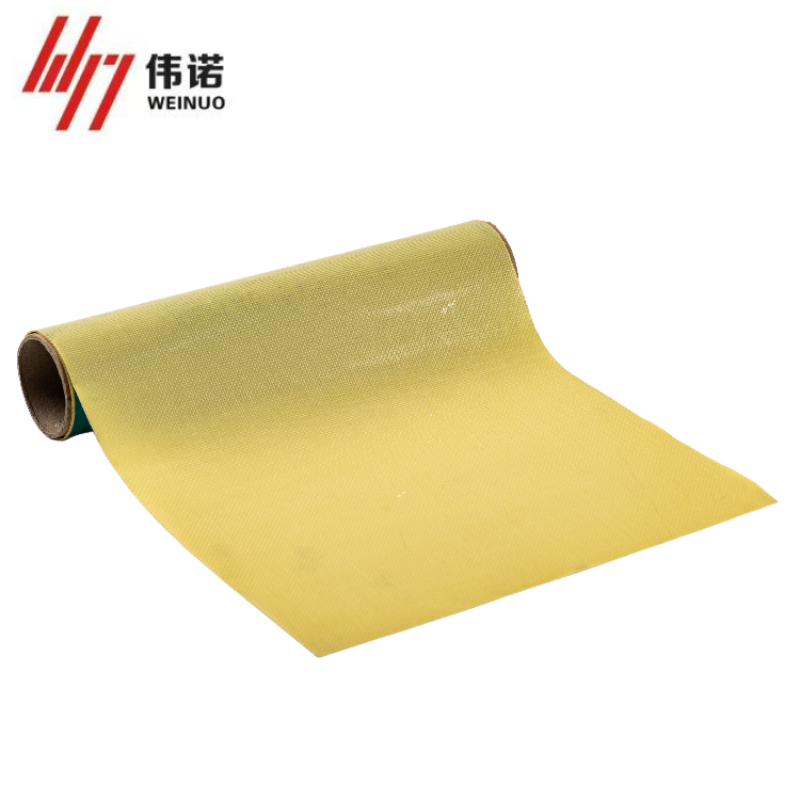

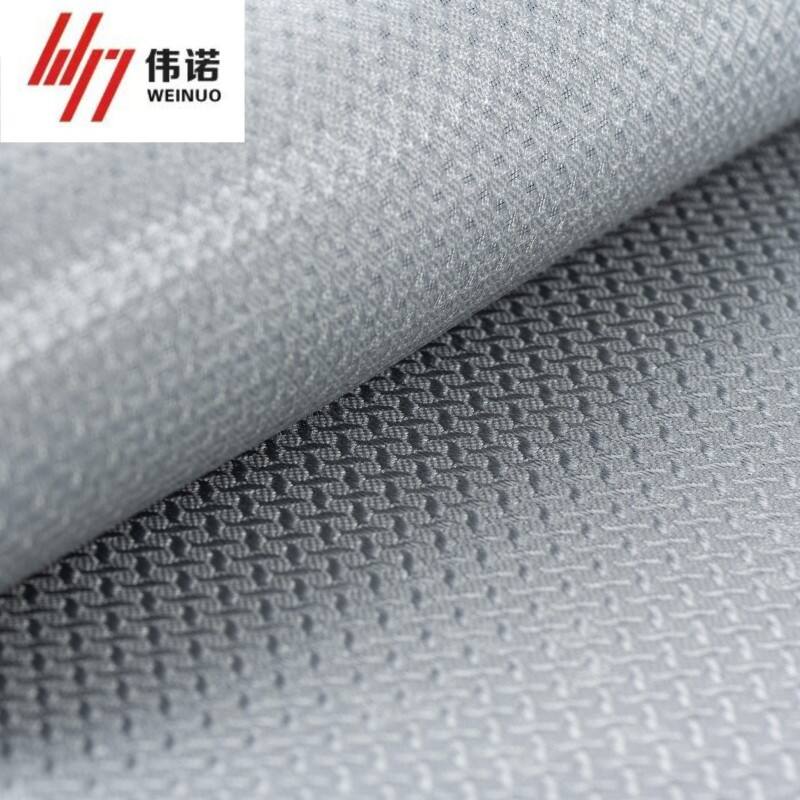

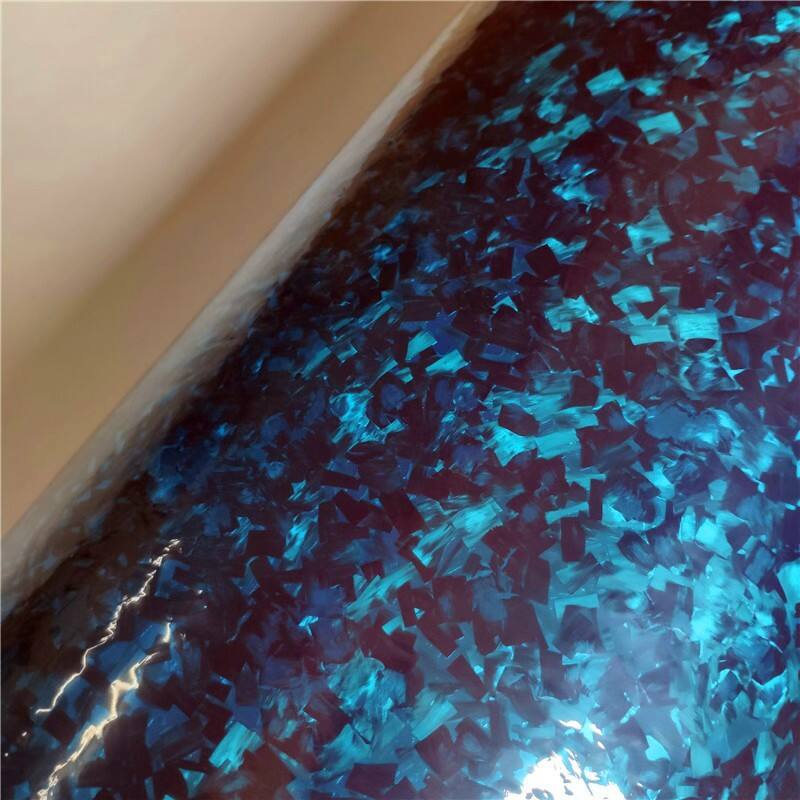

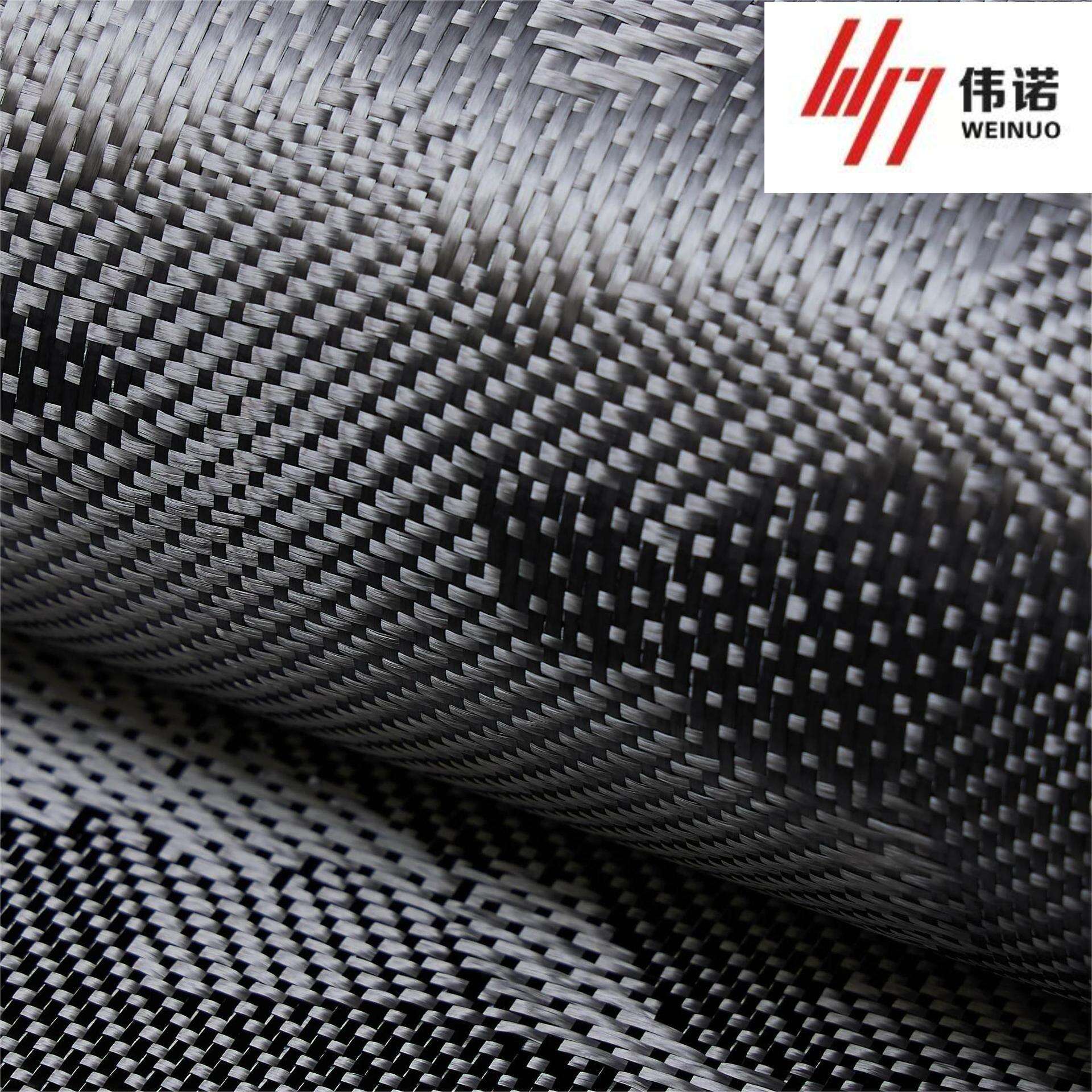

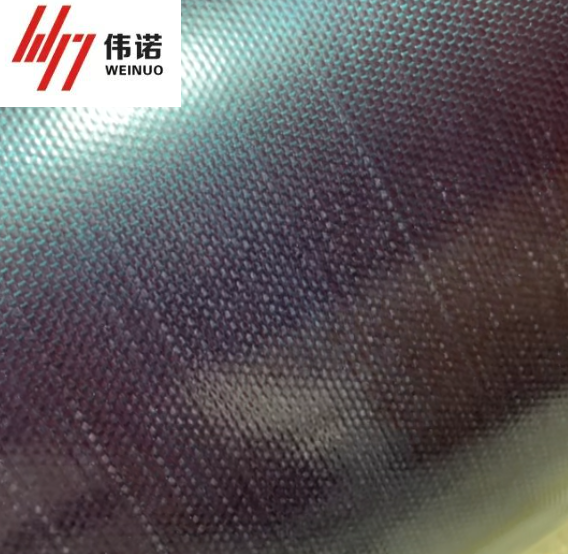

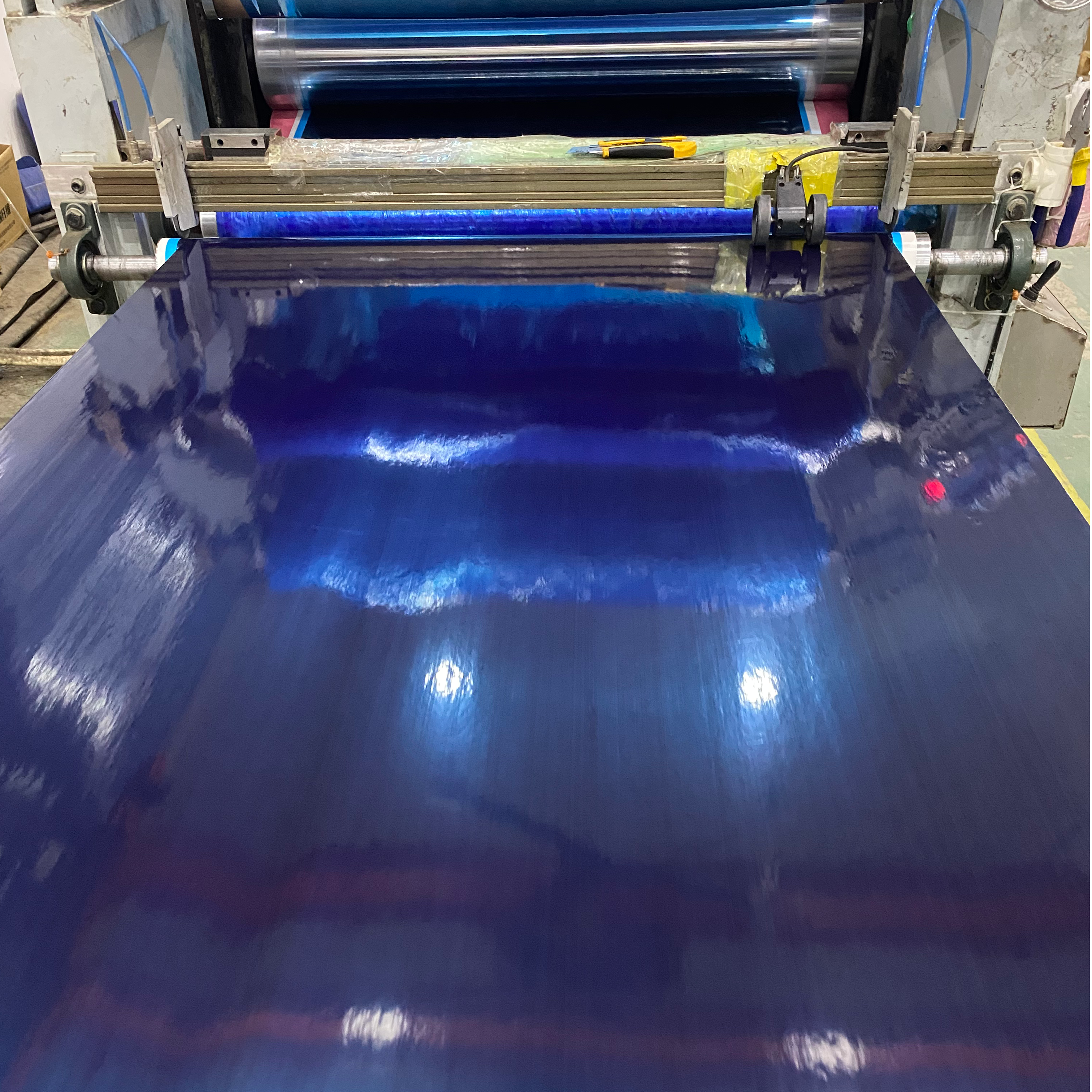

Prepreg carbon fiber suppliers play a crucial role in modern manufacturing by providing advanced composite materials that combine carbon fiber reinforcement with pre-impregnated resin systems. These specialized manufacturers ensure consistent quality and precise fiber-to-resin ratios, delivering materials that offer exceptional strength-to-weight properties. The suppliers maintain strict temperature-controlled environments during production and storage, ensuring the prepreg materials retain their optimal characteristics until use. They typically offer various fiber styles, weave patterns, and resin systems tailored to specific application requirements. Leading suppliers provide comprehensive technical support, including material selection guidance, processing parameters, and quality certification documentation. Their manufacturing processes incorporate advanced automation and quality control systems, ensuring uniform material properties and minimizing variation between production batches. Many suppliers also offer custom solutions, allowing customers to specify particular fiber types, resin systems, and physical properties to meet their unique manufacturing needs. These companies maintain extensive testing facilities to verify material properties and compliance with industry standards, providing customers with detailed material characterization data and processing guidelines.