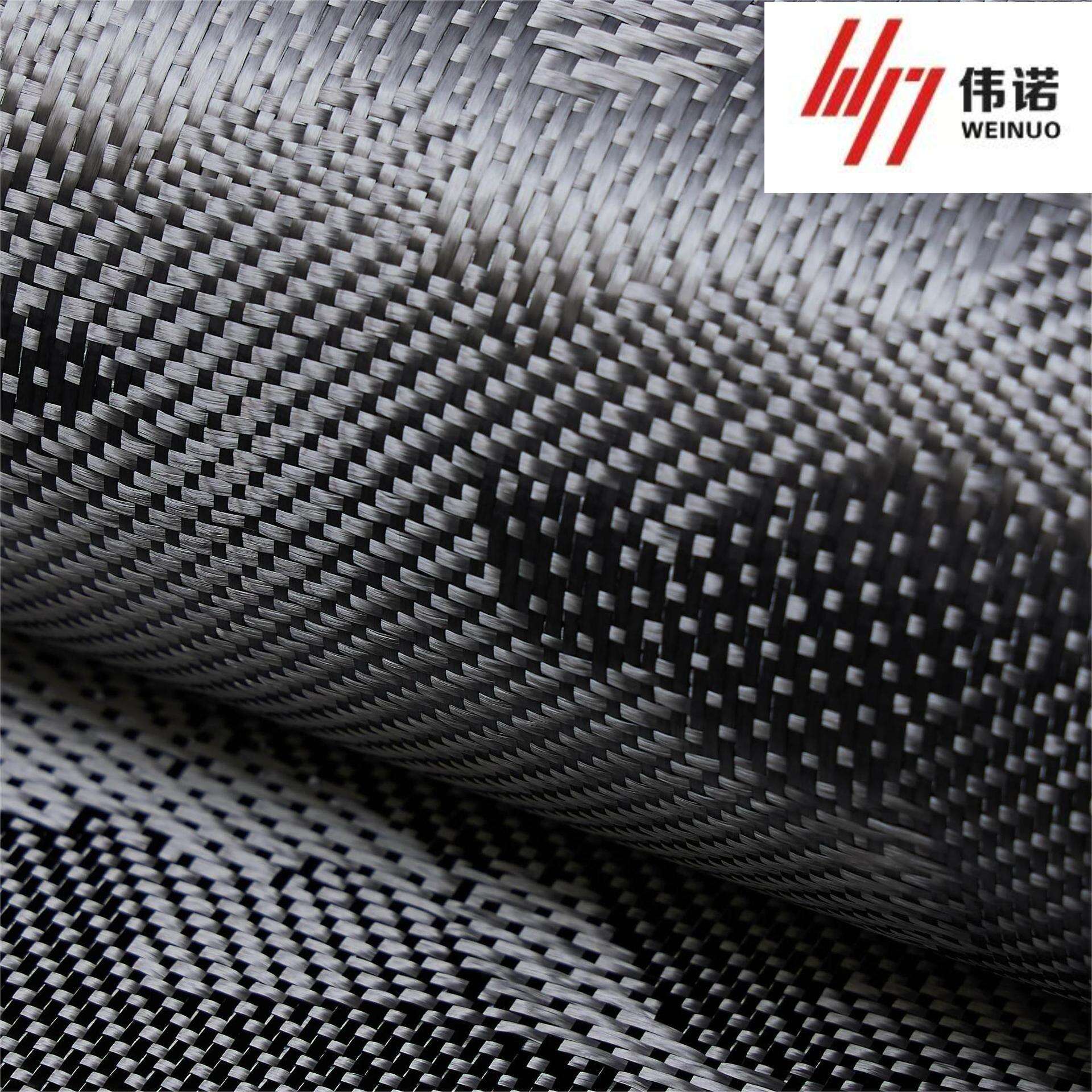

lightweight prepreg carbon fiber

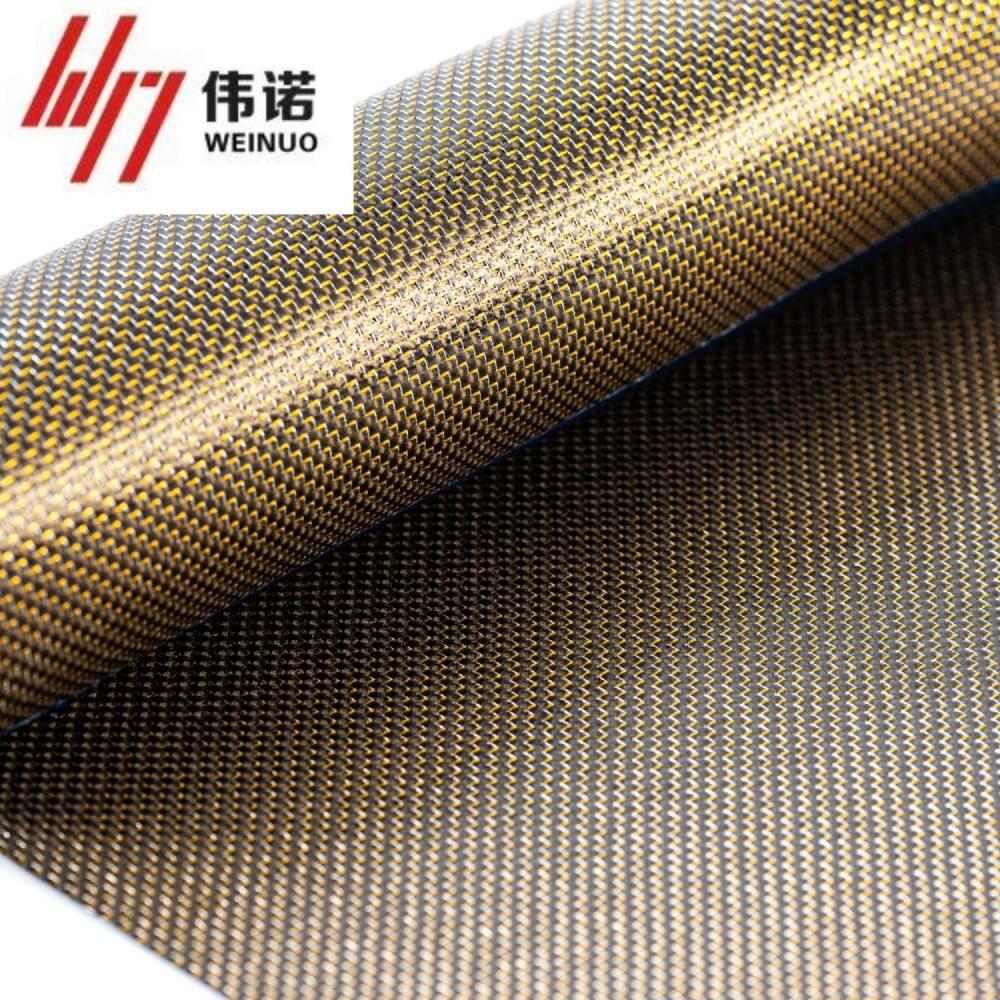

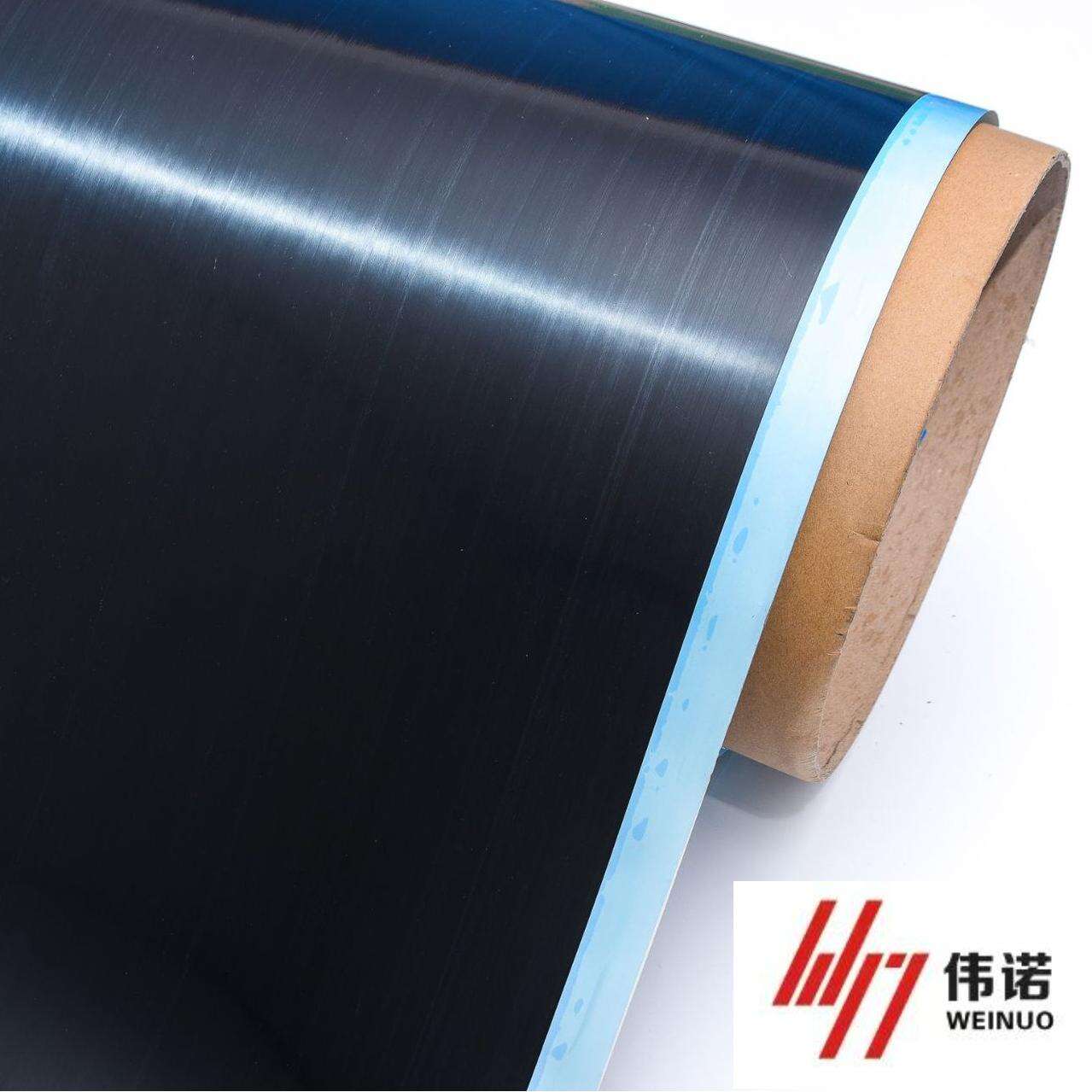

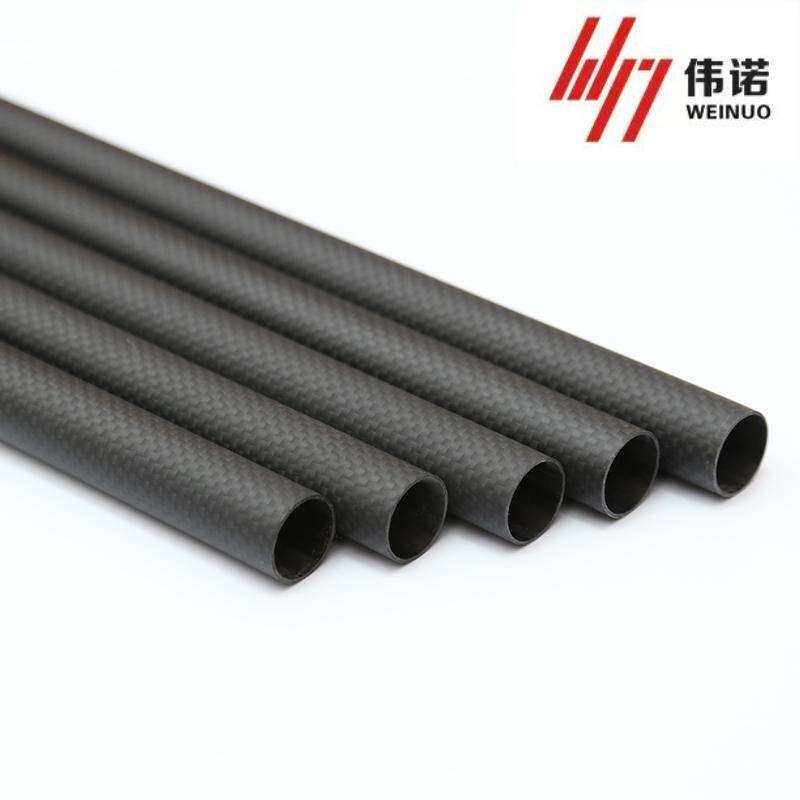

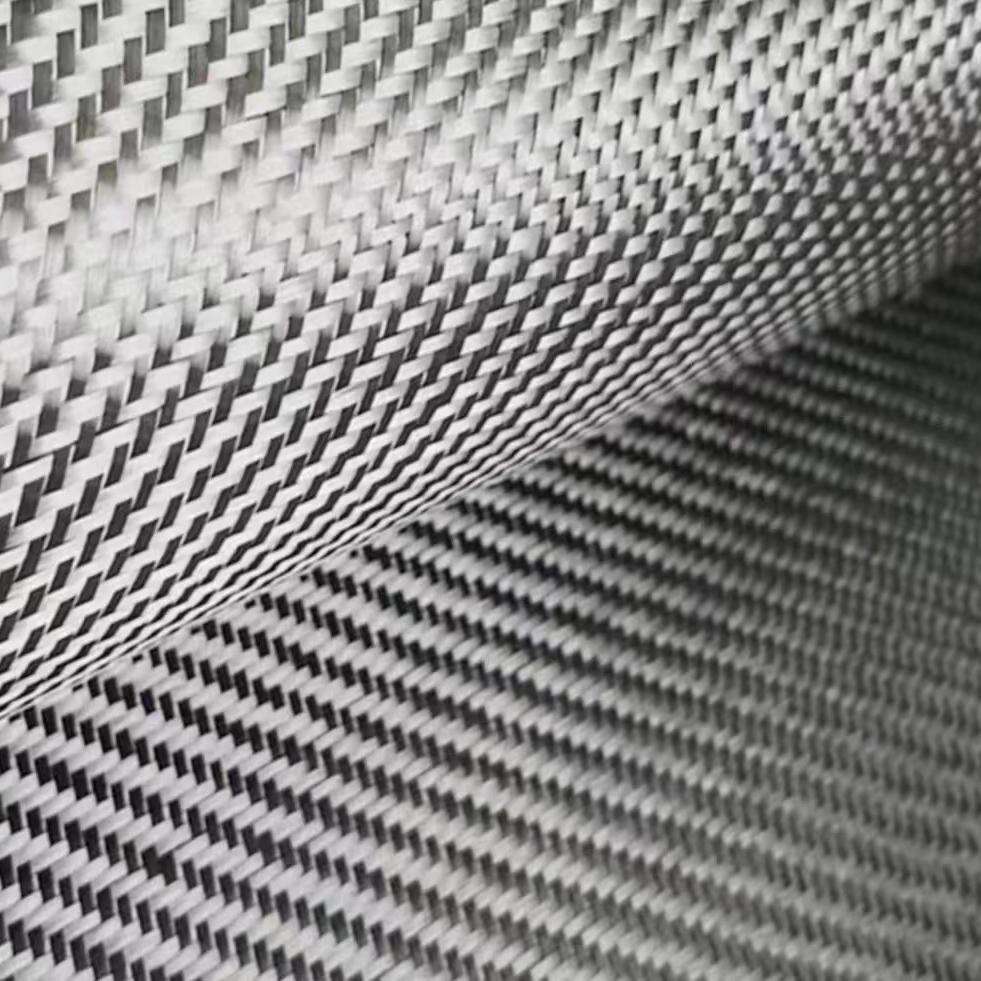

Lightweight prepreg carbon fiber represents a cutting-edge material technology that combines high-strength carbon fibers with pre-impregnated resin systems. This advanced composite material offers an exceptional strength-to-weight ratio, making it invaluable across various industries. The manufacturing process involves precisely controlling the resin content and fiber orientation, resulting in a consistent and reliable product. The prepreg format ensures optimal fiber-to-resin ratios, eliminating the variability often associated with wet layup processes. These materials typically feature thermoset resins that cure under specific temperature and pressure conditions, creating incredibly strong and lightweight structures. The versatility of lightweight prepreg carbon fiber extends to numerous applications, from aerospace components and automotive parts to sporting goods and industrial equipment. Its ability to be molded into complex shapes while maintaining structural integrity has revolutionized product design and manufacturing capabilities. The material's exceptional fatigue resistance and dimensional stability make it particularly suitable for high-performance applications where weight reduction is crucial without compromising strength. Modern lightweight prepreg carbon fiber systems also incorporate advanced resin technologies that offer improved processing characteristics, enhanced environmental resistance, and better surface finish quality.