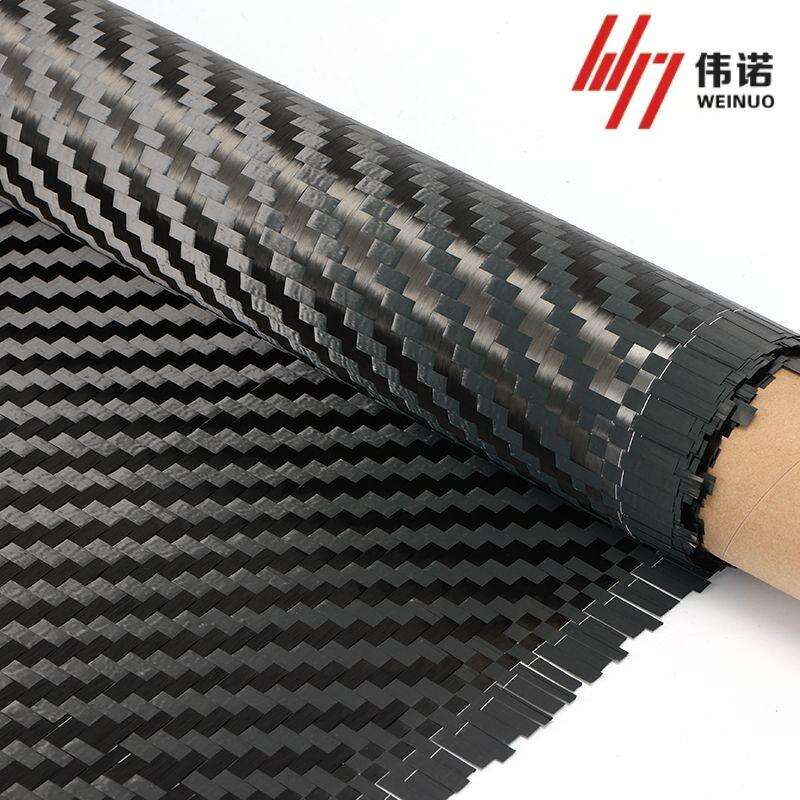

twill carbon fiber fabrics roll

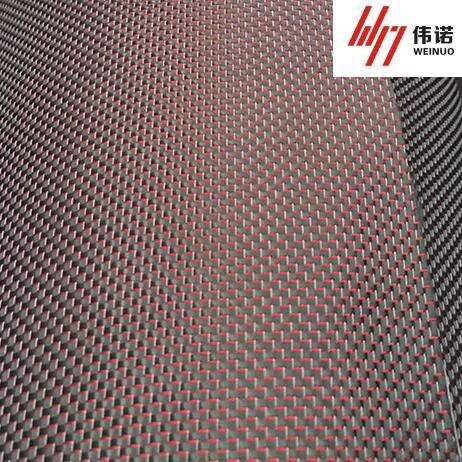

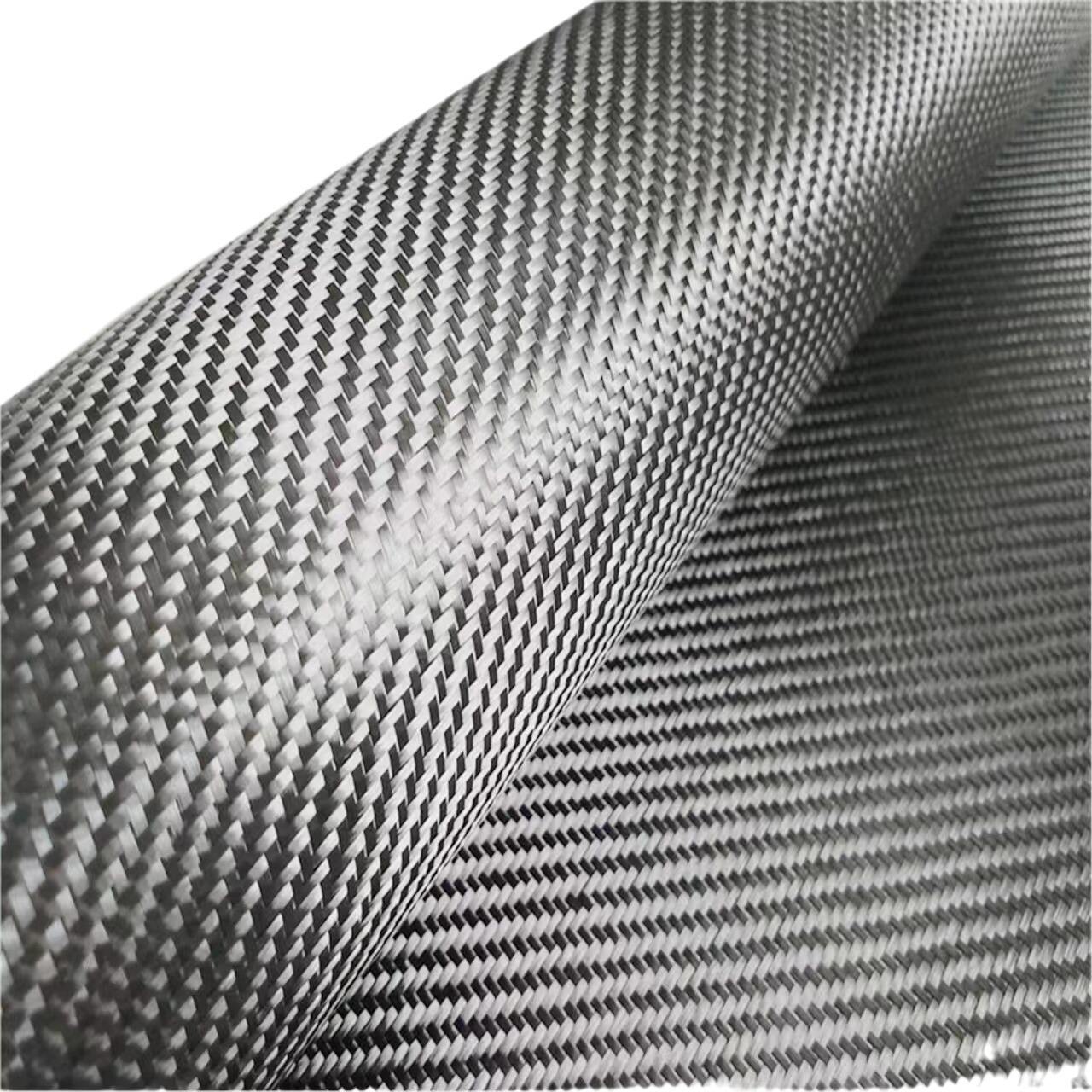

Twill carbon fiber fabrics roll represents a pinnacle in advanced composite materials, offering a distinctive 2x2 weave pattern that provides superior strength and aesthetic appeal. This specialized fabric consists of carbon fiber tows woven in a repeating pattern where each warp fiber passes over two weft fibers before going under two, creating a characteristic diagonal pattern. The roll format ensures efficient material handling and consistent quality across large-scale applications. With its exceptional strength-to-weight ratio, twill carbon fiber fabric delivers outstanding mechanical properties while maintaining flexibility and workability. The material exhibits remarkable resistance to fatigue, corrosion, and temperature variations, making it ideal for demanding applications. The twill weave pattern not only enhances the fabric's draping capabilities but also provides better conformability to complex shapes compared to plain weave alternatives. These rolls typically come in various widths and lengths to accommodate different project requirements, with standardized fiber orientations that ensure predictable performance characteristics. The material's inherent properties include excellent tensile strength, high modulus of elasticity, and superior impact resistance, making it a preferred choice in aerospace, automotive, and high-performance sporting goods manufacturing.