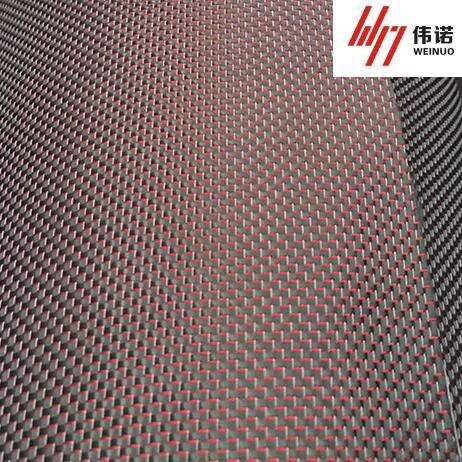

jacquard carbon fiber fabric honeycomb hexagon

The jacquard carbon fiber fabric honeycomb hexagon represents a groundbreaking advancement in composite material technology, combining the aesthetic appeal of jacquard weaving with the exceptional strength of carbon fiber in a distinctive hexagonal pattern. This innovative material features a sophisticated honeycomb structure that maximizes strength while minimizing weight, making it ideal for high-performance applications. The hexagonal pattern is precisely engineered through advanced jacquard weaving techniques, creating a three-dimensional structure that enhances both structural integrity and visual appeal. Each hexagonal cell works in harmony to distribute force evenly across the material, providing superior impact resistance and structural stability. The carbon fiber composition delivers exceptional strength-to-weight ratio, while the jacquard weaving process allows for intricate pattern customization and optimal fiber orientation. This material excels in applications requiring both aesthetic sophistication and technical performance, from automotive components to aerospace structures and high-end sporting equipment. The combination of the honeycomb structure with carbon fiber properties results in enhanced thermal stability, vibration dampening, and superior fatigue resistance.