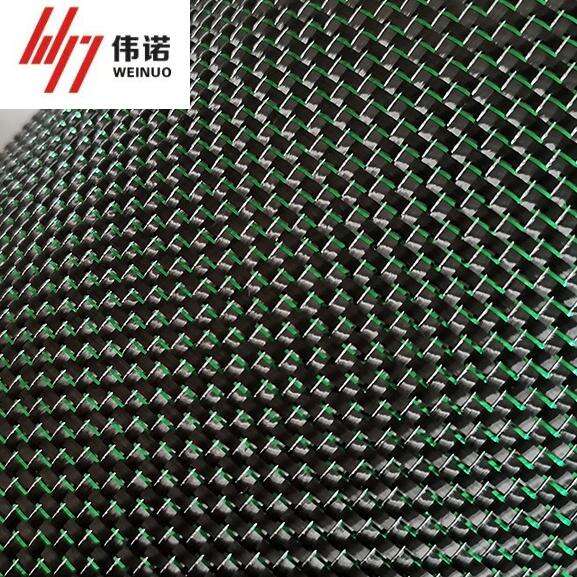

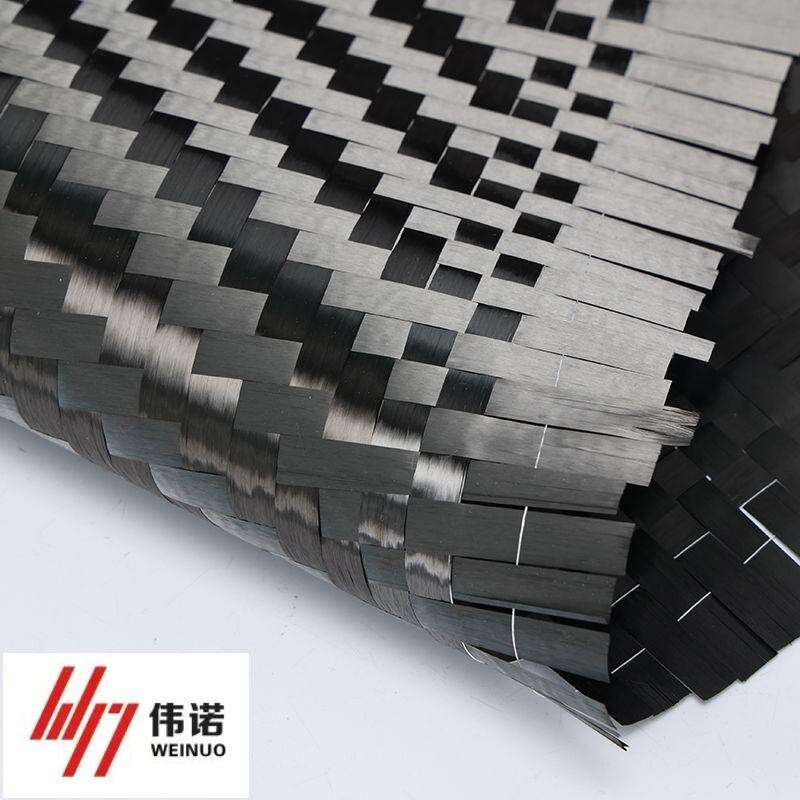

cfrp fabric

CFRP (Carbon Fiber Reinforced Polymer) fabric represents a groundbreaking advancement in composite materials technology. This innovative material consists of high-strength carbon fibers woven into a flexible fabric matrix, which is then combined with polymer resins to create extraordinarily strong and lightweight structures. The fabric's unique composition allows it to deliver exceptional mechanical properties, including superior tensile strength and remarkable resistance to fatigue. In construction and infrastructure applications, CFRP fabric serves as a critical reinforcement material, enabling structural rehabilitation and seismic retrofitting of existing buildings and bridges. The aerospace and automotive industries extensively utilize CFRP fabric for manufacturing lightweight components that significantly improve fuel efficiency while maintaining structural integrity. Its versatility extends to sporting goods, where it enhances the performance of equipment such as tennis rackets, golf clubs, and bicycle frames. The fabric's corrosion resistance and durability make it particularly valuable in marine environments and chemical processing facilities. Modern manufacturing techniques have made CFRP fabric increasingly accessible, while continuous research and development efforts have expanded its applications across various industrial sectors.