carbon fabric for drones

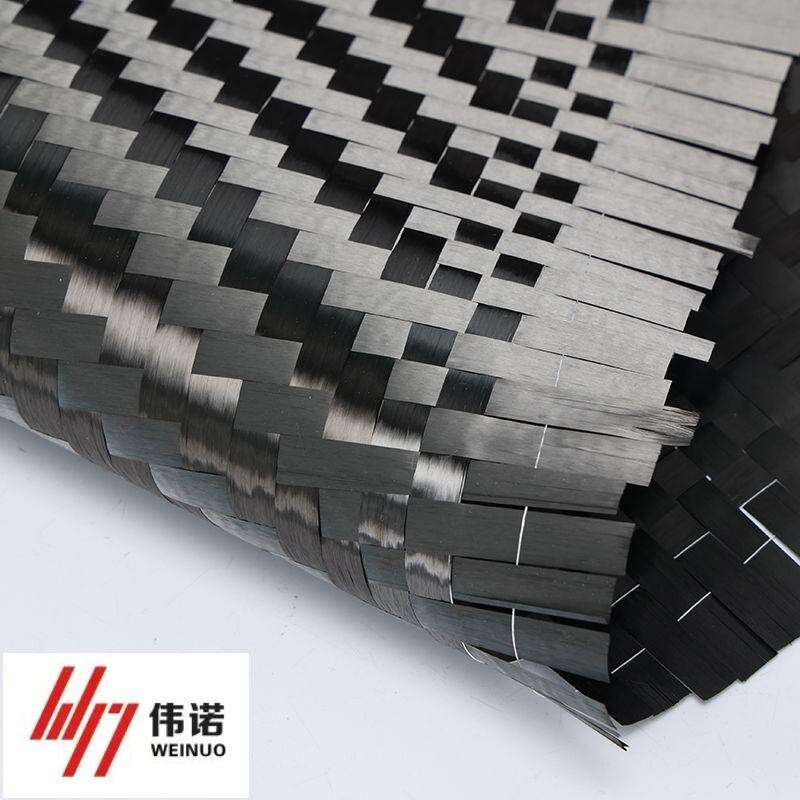

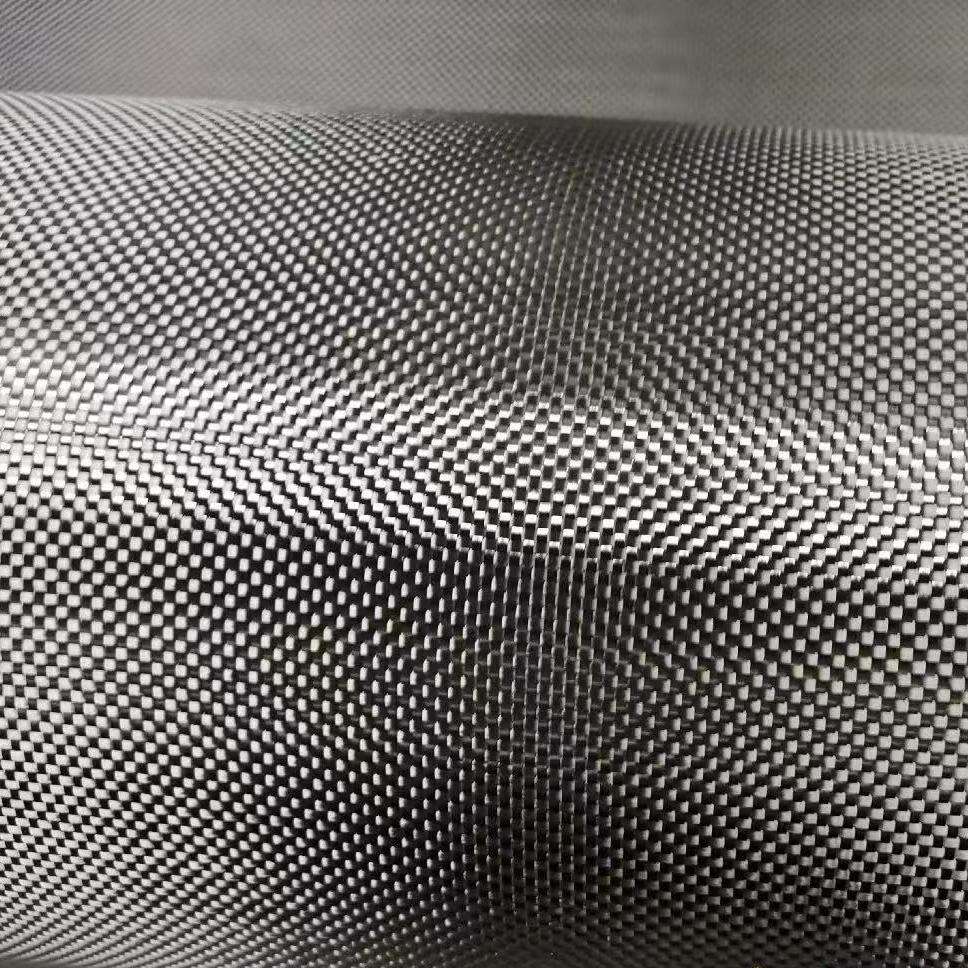

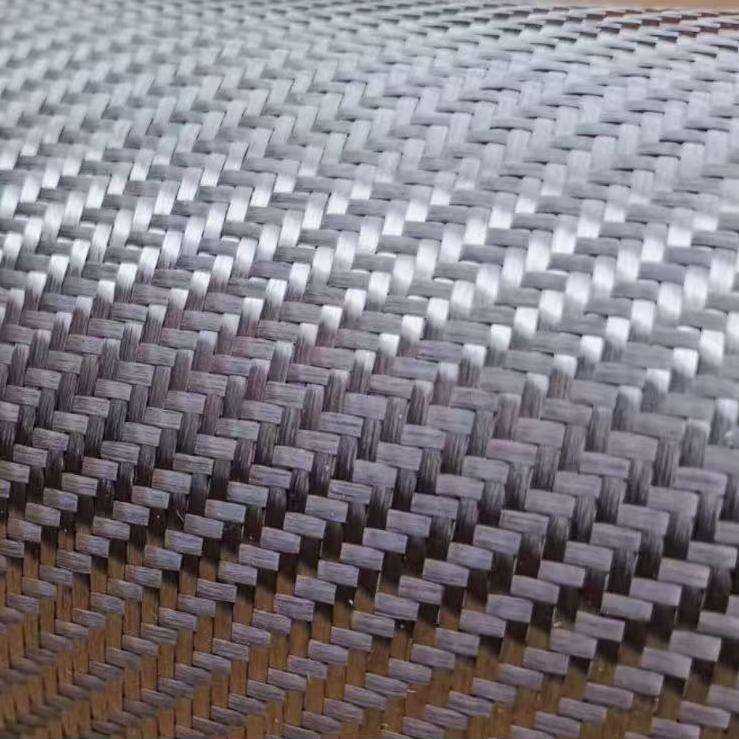

Carbon fabric for drones represents a cutting-edge material solution that has revolutionized the drone manufacturing industry. This advanced composite material consists of interwoven carbon fibers that create an exceptionally strong yet lightweight structure, making it ideal for drone applications. The fabric's unique molecular structure provides an outstanding strength-to-weight ratio, enabling drones to achieve optimal performance while maintaining structural integrity. The material undergoes specialized treatment processes to enhance its durability and resistance to environmental factors, including UV radiation and moisture. Carbon fabric's versatility allows it to be molded into various shapes and configurations, facilitating aerodynamic designs that improve flight efficiency. The material's inherent properties include excellent thermal conductivity, which helps in heat dissipation during flight operations, and superior vibration dampening characteristics that protect sensitive electronic components. Modern manufacturing techniques enable the integration of different weave patterns and fiber orientations, allowing manufacturers to optimize the fabric's properties for specific drone applications, from racing drones to professional aerial photography platforms.