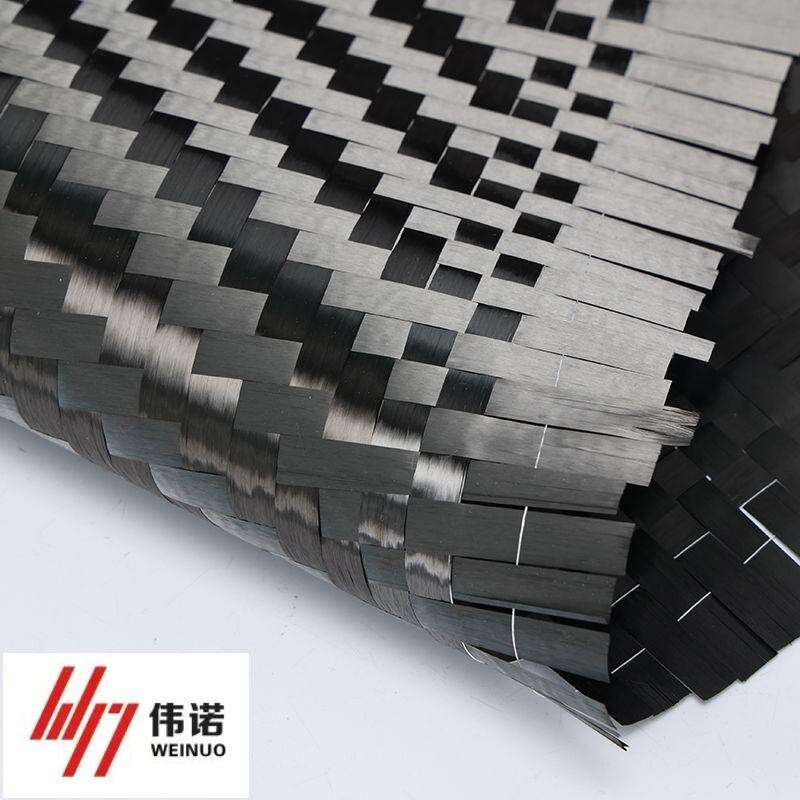

unidirectional fabric

Unidirectional fabric represents a groundbreaking advancement in composite materials, characterized by its unique fiber arrangement where all fibers run parallel in a single direction. This specialized construction method creates a material with exceptional strength along the fiber orientation, making it particularly valuable in applications requiring high tensile strength in specific directions. The fabric is manufactured through a precise process where continuous fibers are aligned and held together by a minimal amount of cross-stitching or a light backing material. This structure allows for maximum fiber content in the load-bearing direction, resulting in superior mechanical properties. The material typically consists of carbon, glass, or aramid fibers, each offering distinct performance characteristics. What sets unidirectional fabric apart is its ability to be engineered for specific load requirements, allowing designers to optimize material usage by placing fibers exactly where strength is needed. This targeted reinforcement capability makes it an ideal choice for applications in aerospace, automotive, sporting goods, and civil engineering structures. The fabric's versatility extends to its compatibility with various resin systems, enabling it to be integrated into both thermoset and thermoplastic composite solutions. Furthermore, its uniform fiber distribution ensures consistent performance and predictable mechanical properties, essential for critical structural applications.