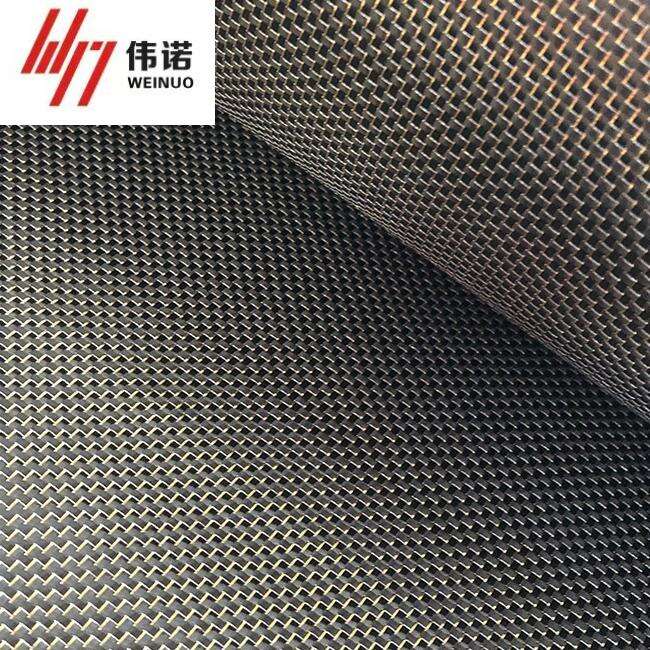

3d woven carbon fiber

3D woven carbon fiber represents a groundbreaking advancement in composite materials technology, offering unprecedented structural integrity and performance capabilities. This innovative material is created through a complex weaving process that interlaces carbon fiber tows in three orthogonal directions, creating a fully integrated structure. Unlike traditional layered composites, 3D woven carbon fiber features fibers oriented in the x, y, and z directions, resulting in superior mechanical properties and damage resistance. The material's unique architecture enables enhanced load distribution and exceptional resistance to delamination, a common failure mode in conventional composite materials. The manufacturing process involves sophisticated weaving machinery capable of producing near-net-shape preforms, significantly reducing material waste and processing time. These structural materials find extensive applications in aerospace, automotive, and high-performance sporting goods, where their exceptional strength-to-weight ratio and durability are paramount. The material's ability to be customized through fiber architecture manipulation allows engineers to optimize properties for specific applications, making it an invaluable solution for demanding structural requirements.