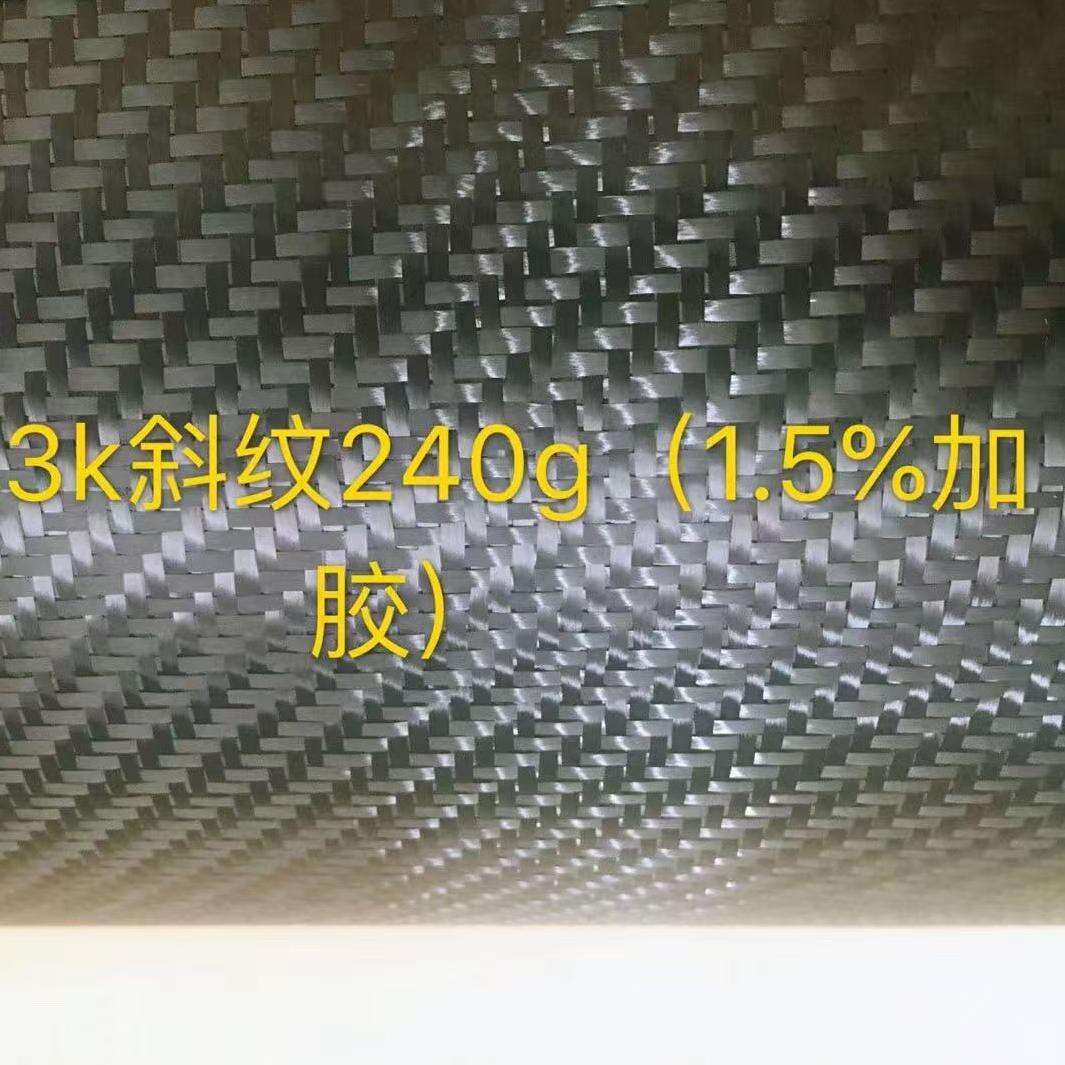

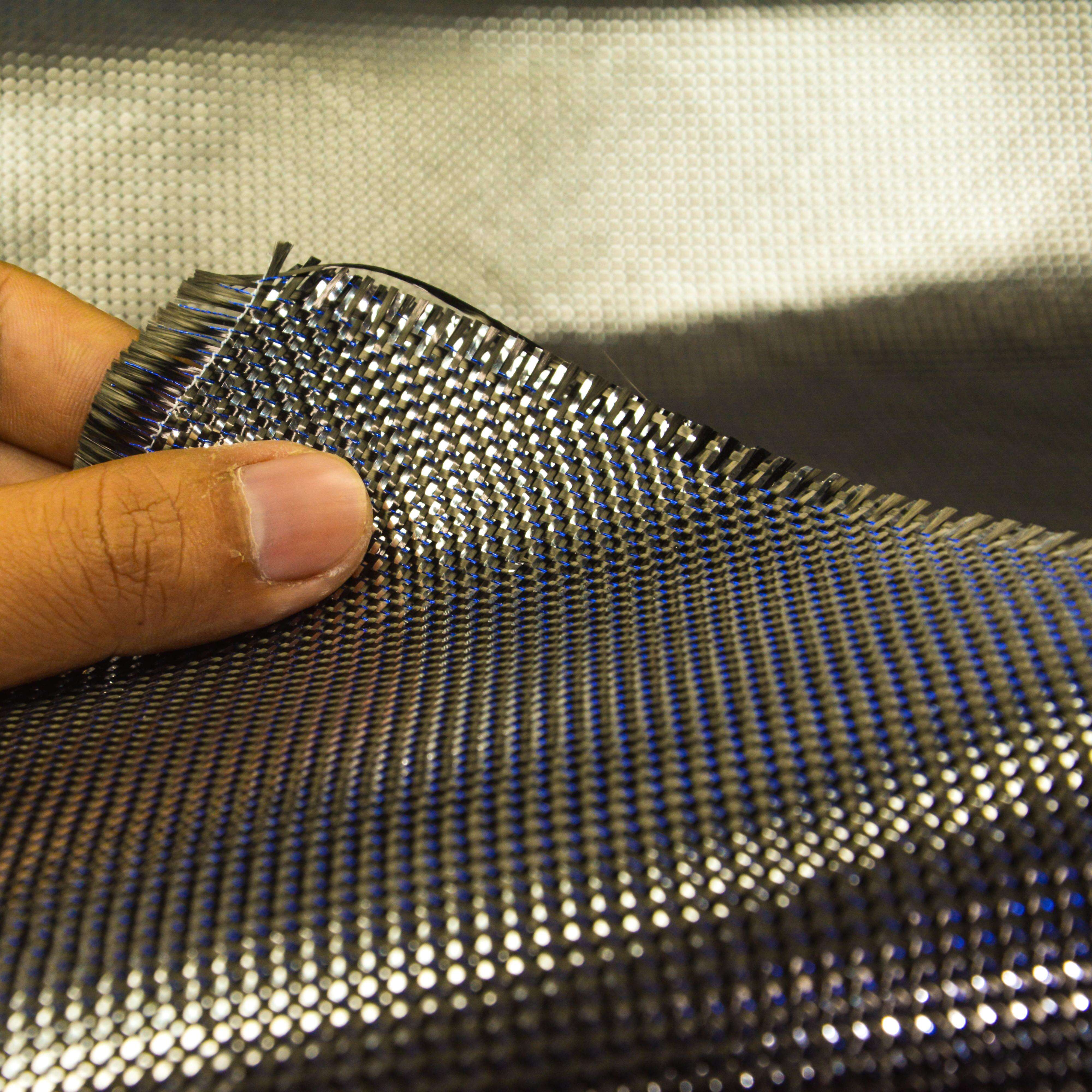

carbon fiber textile

Carbon fiber textile represents a revolutionary advancement in material science, combining lightweight properties with exceptional strength. This innovative material consists of carefully woven carbon fiber strands, typically 5-10 micrometers in diameter, created through a complex process of oxidation, carbonization, and surface treatment of organic fibers. The resulting textile exhibits remarkable tensile strength, up to five times stronger than steel while weighing about one-third as much. Its unique molecular structure allows for superior heat resistance, with the ability to maintain structural integrity at temperatures exceeding 2000°C. The material's versatility extends across multiple industries, from aerospace and automotive applications to sporting goods and architectural solutions. Carbon fiber textile's distinctive characteristics include excellent fatigue resistance, low thermal expansion, and high chemical resistance, making it ideal for demanding environmental conditions. The manufacturing process ensures precise fiber alignment, creating a material that can be customized for specific load-bearing requirements while maintaining its lightweight nature. Modern applications have expanded to include protective gear, medical devices, and advanced composites for renewable energy infrastructure.