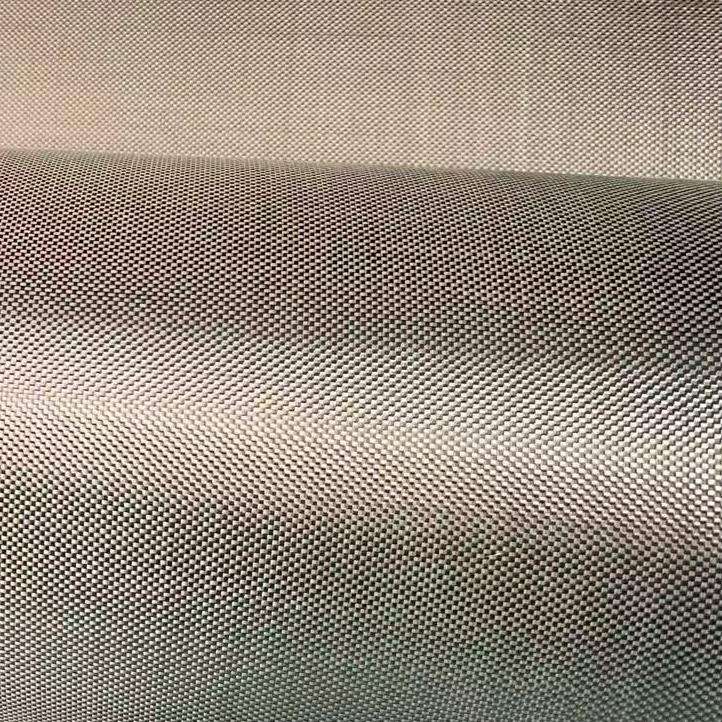

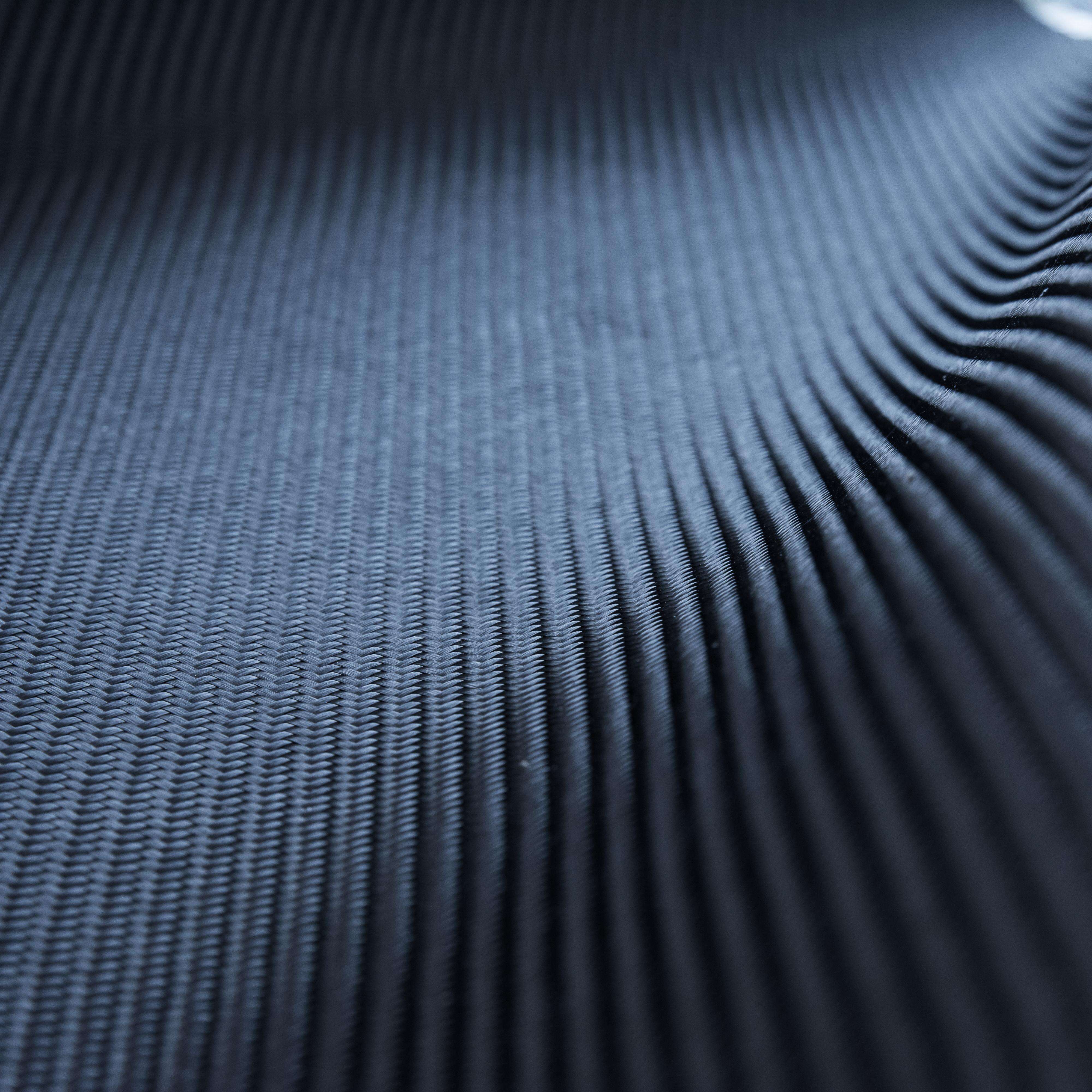

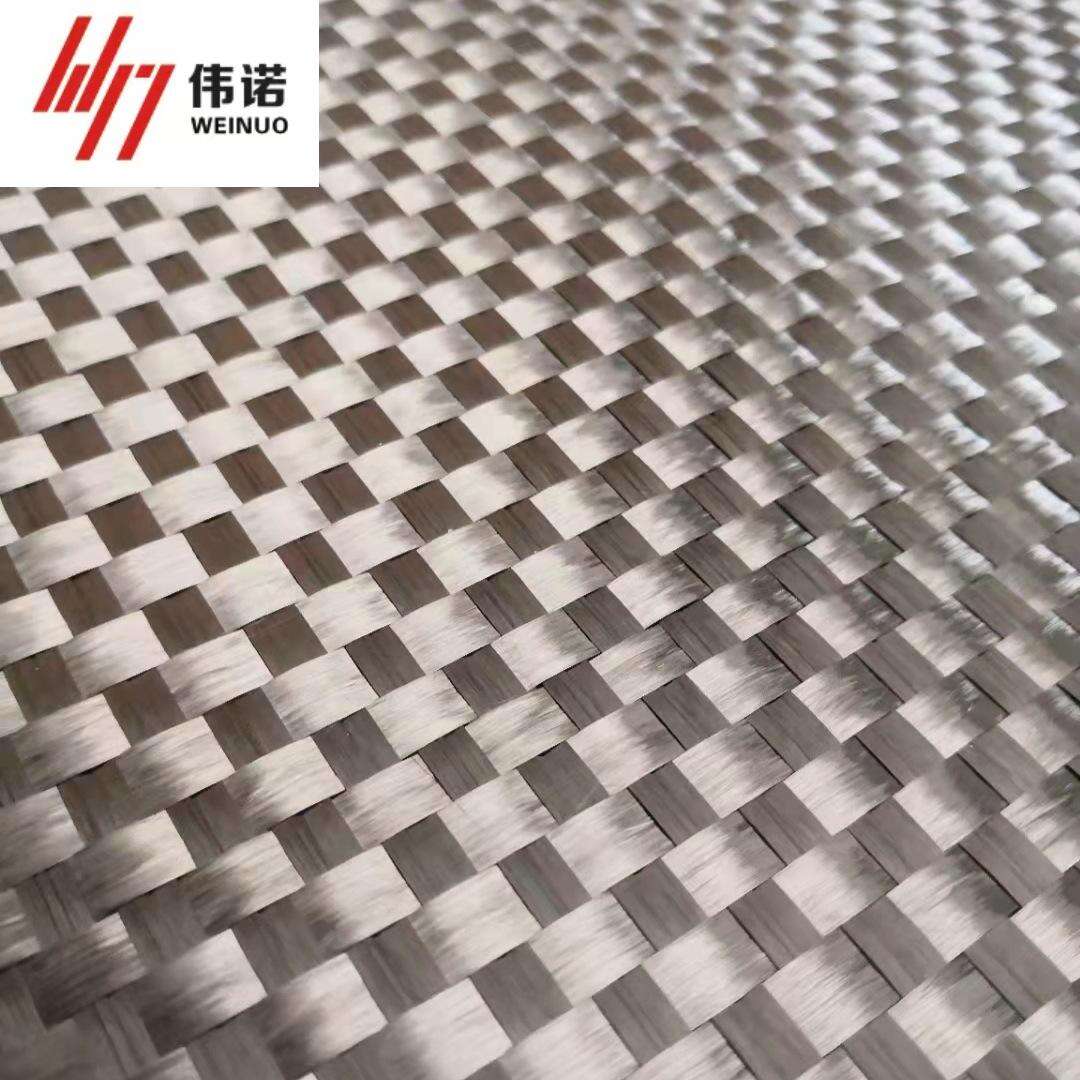

3d pattern diamond pattern carbon fiber fabrics

3D pattern diamond pattern carbon fiber fabrics represent an advanced material innovation in composite manufacturing, combining aesthetic appeal with superior structural integrity. These specialized fabrics feature a distinctive diamond pattern woven into a three-dimensional structure, creating a unique visual appearance while enhancing mechanical properties. The fabric's construction involves precision weaving of carbon fiber threads in multiple directions, resulting in a complex geometric pattern that provides enhanced strength and durability. This advanced textile engineering creates a material that excels in both form and function, offering improved resistance to impact, superior load distribution, and enhanced structural stability. The 3D pattern configuration allows for better resin penetration during composite manufacturing, ensuring thorough wet-out and optimal bonding between layers. These fabrics are particularly valued in high-end applications where both appearance and performance are crucial, such as automotive components, aerospace structures, and luxury consumer goods. The diamond pattern not only serves an aesthetic purpose but also contributes to the material's overall strength by providing multiple load paths and enhanced interlaminar properties.