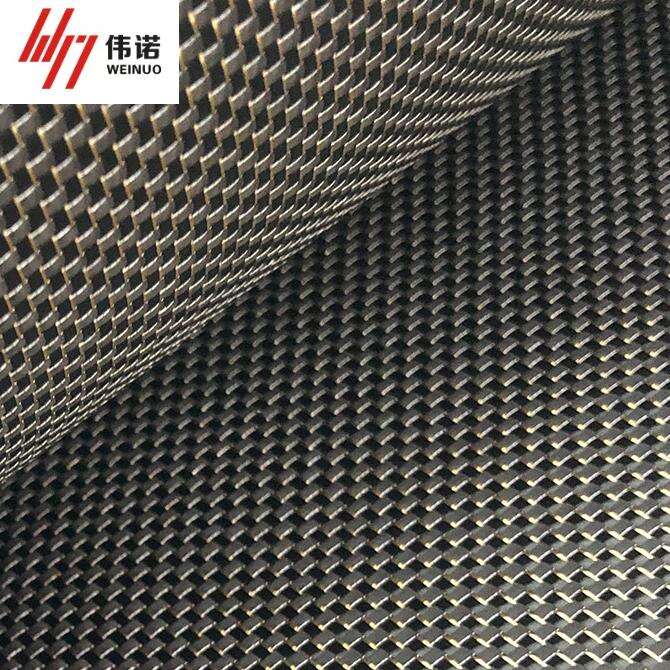

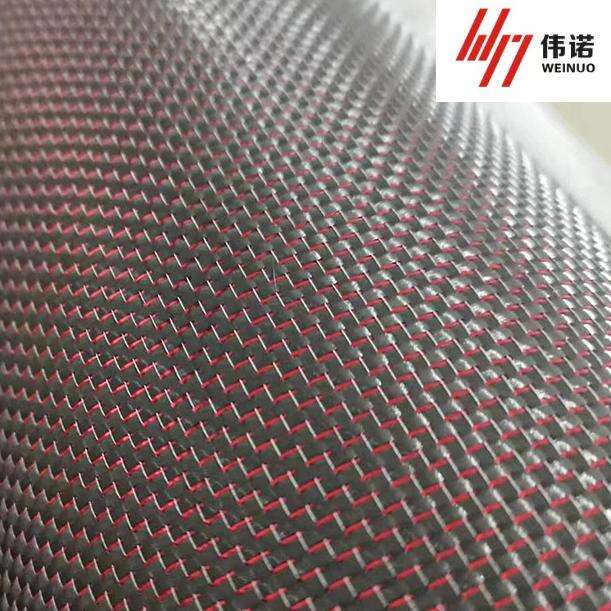

6k carbon fiber

6k carbon fiber represents a significant advancement in composite material technology, offering an innovative balance of strength, weight, and versatility. This advanced material features 6,000 carbon filaments per fiber tow, creating a dense and uniform structure that enhances overall performance. The distinctive characteristics of 6k carbon fiber include its exceptional strength-to-weight ratio, superior tensile strength, and remarkable resistance to environmental factors. In manufacturing processes, 6k carbon fiber demonstrates excellent workability and consistency, making it ideal for both industrial and consumer applications. The material's structural integrity is maintained through a sophisticated weaving process that ensures even distribution of stress loads and optimal fiber orientation. Its applications span across multiple industries, including aerospace, automotive manufacturing, sporting goods, and high-performance equipment production. The 6k configuration provides an optimal balance between fiber density and resin penetration, resulting in composites that exhibit superior mechanical properties while maintaining processability. This material has become particularly valuable in applications requiring high strength, low weight, and dimensional stability under varying conditions. The versatility of 6k carbon fiber allows for its implementation in both structural and aesthetic applications, making it a preferred choice for engineers and designers seeking to optimize performance while maintaining manufacturing efficiency.