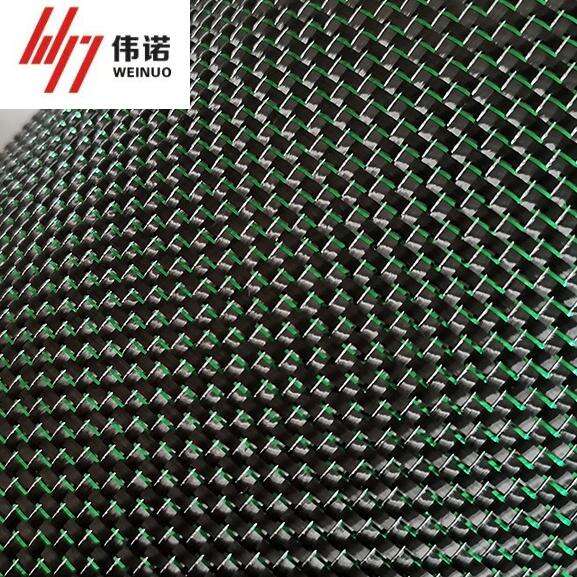

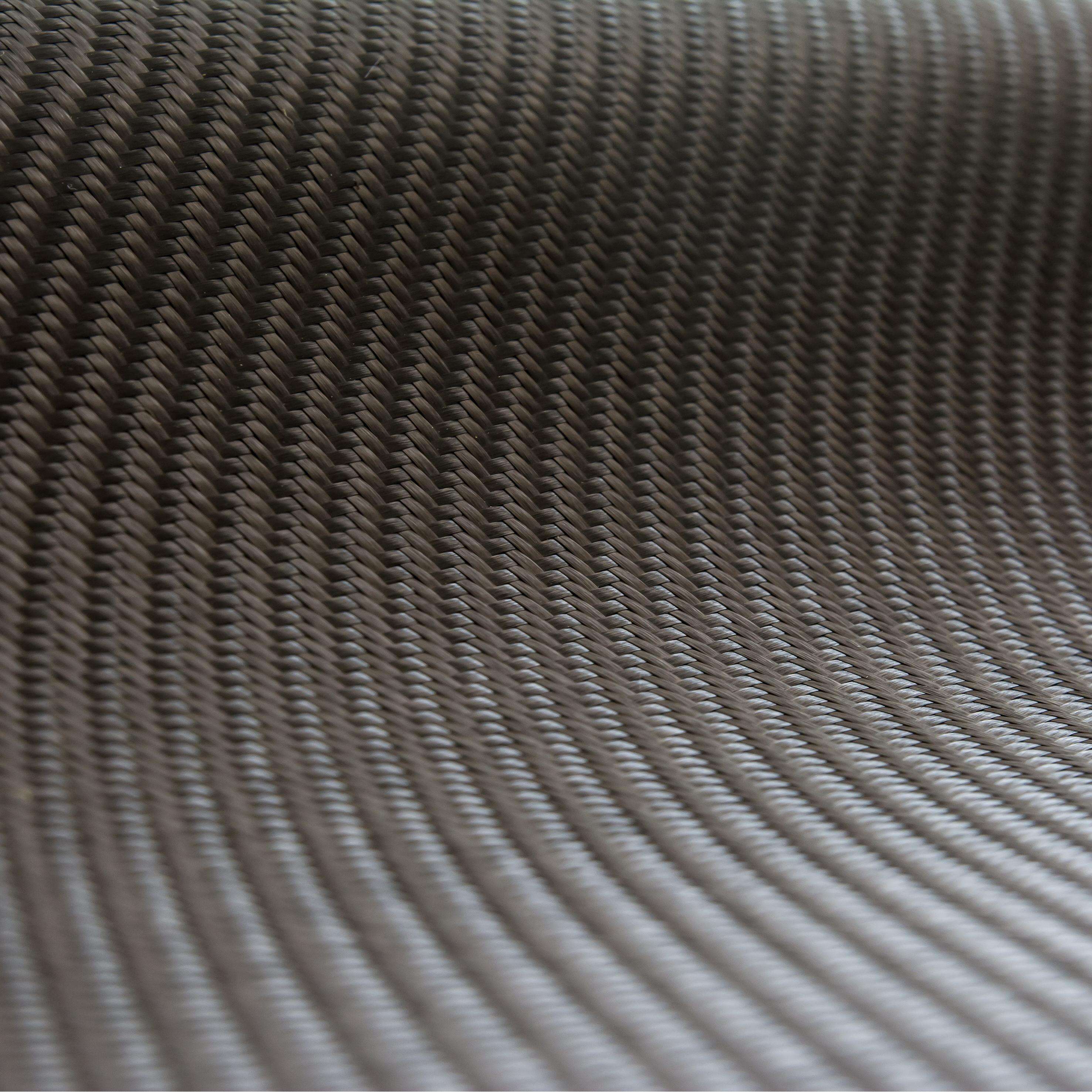

3k plain weave carbon fiber

3k plain weave carbon fiber represents a sophisticated composite material characterized by its distinctive weaving pattern, where three thousand carbon fiber filaments are bundled into each tow before being interlaced in a simple over-under pattern. This construction creates a balanced and symmetrical fabric that offers exceptional strength-to-weight properties. The material's structure consists of yarns that cross at 90-degree angles, creating a stable and predictable weave pattern that's ideal for various applications. The '3k' designation refers to the number of carbon filaments in each tow, approximately 3,000, which results in a medium-weight fabric that strikes an optimal balance between strength and flexibility. This versatile material exhibits remarkable mechanical properties, including high tensile strength, excellent fatigue resistance, and superior dimensional stability. Its uniform appearance and consistent mechanical properties make it particularly suitable for visible applications where aesthetics are as important as performance. The material's inherent characteristics include exceptional resistance to temperature extremes, chemical inertness, and minimal thermal expansion, making it invaluable in aerospace, automotive, and high-performance sporting goods manufacturing.