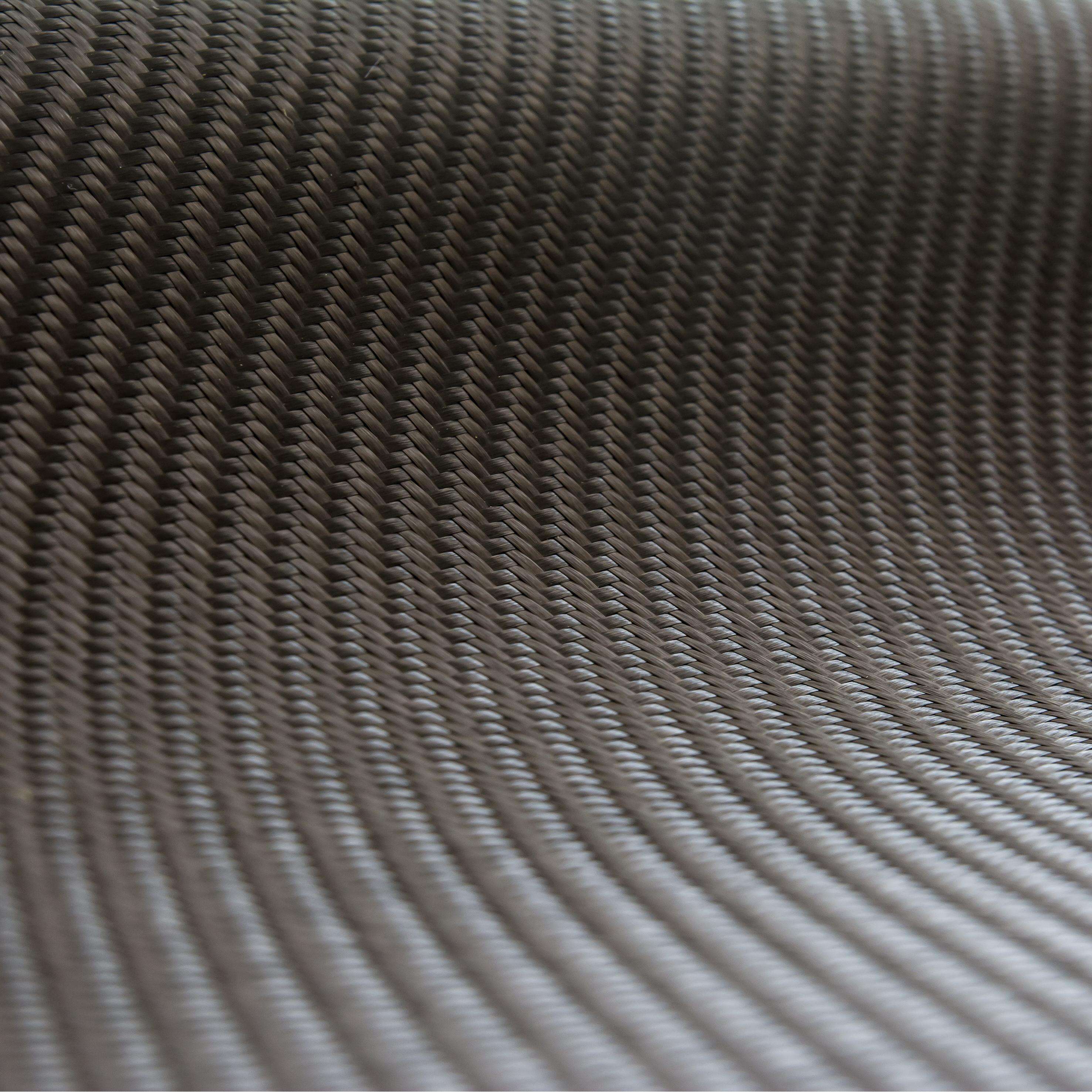

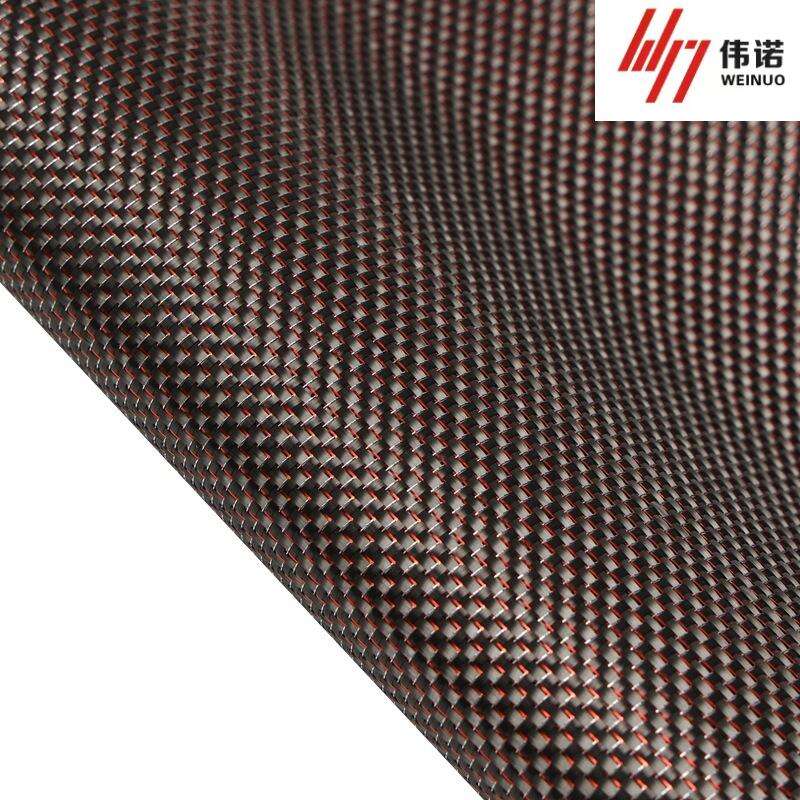

carbon fiber fabric

Carbon fiber fabric represents a revolutionary advancement in material science, combining exceptional strength with remarkably low weight. This sophisticated material consists of thin, strong crystalline filaments of carbon that are woven together to create a durable textile. The fabric's structure typically features thousands of carbon fibers bundled together to form a tow, which is then woven into various patterns, each optimized for specific applications. These patterns can include plain weave, twill weave, or more complex arrangements, determining the fabric's final characteristics. The material exhibits outstanding tensile strength, often exceeding that of steel while weighing significantly less. Carbon fiber fabric also demonstrates excellent resistance to temperature changes, chemical exposure, and fatigue, making it ideal for demanding applications. Its versatility allows for implementation across numerous industries, from aerospace and automotive manufacturing to sporting goods and architectural applications. The fabric can be impregnated with resins to create composite materials, further enhancing its structural properties. Modern manufacturing processes enable the production of carbon fiber fabric in various weights, weave patterns, and surface treatments, allowing customization for specific performance requirements.