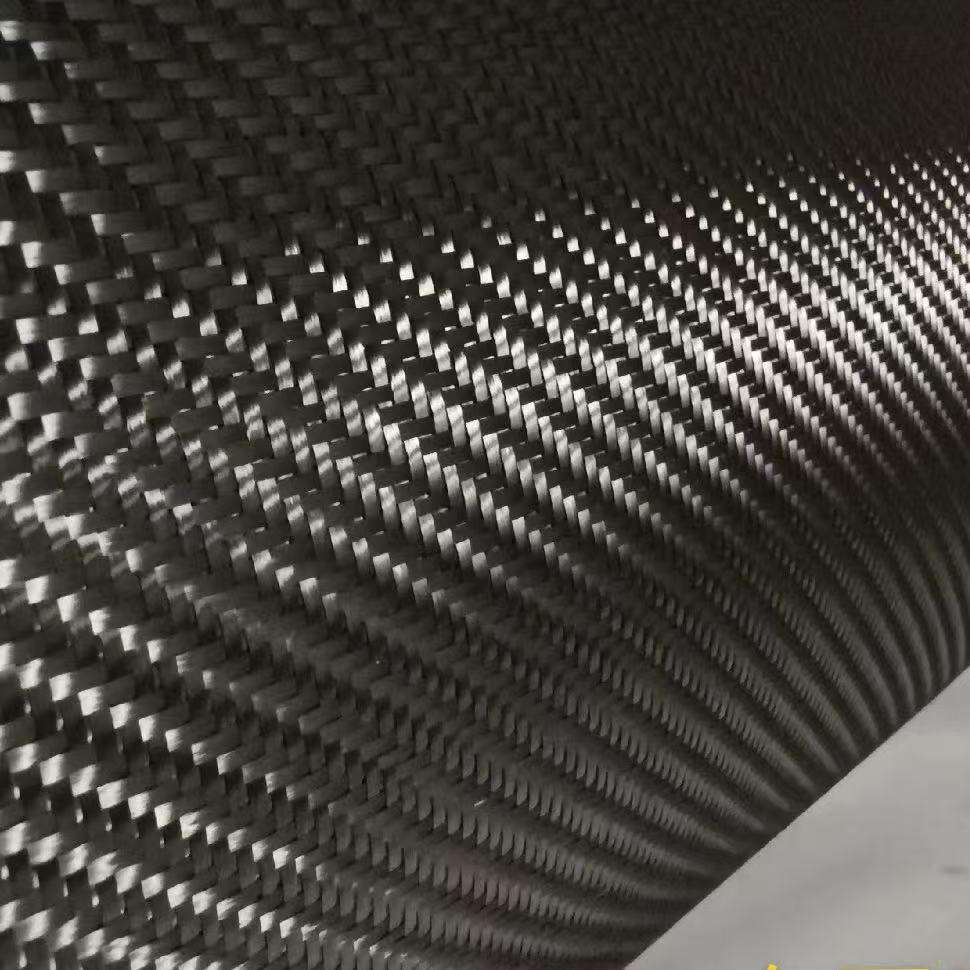

carbon fiber fabrics roll for automotives

Carbon fiber fabrics roll for automotives represents a revolutionary advancement in vehicle manufacturing, offering an optimal blend of strength, lightweight properties, and design flexibility. This innovative material consists of carefully woven carbon fibers arranged in continuous rolls, specifically engineered for automotive applications. The fabric's unique structure allows for exceptional tensile strength while maintaining minimal weight, making it ideal for modern vehicle construction. These rolls are manufactured through a sophisticated process that ensures consistent fiber orientation and density, resulting in reliable mechanical properties across the entire material. When applied in automotive manufacturing, these fabric rolls can be easily shaped and molded to create various components, from body panels to structural elements. The material's versatility enables manufacturers to achieve superior aerodynamic designs while maintaining structural integrity. Additionally, these fabric rolls are treated with specialized resins and coatings that enhance their durability and resistance to environmental factors. The precise weaving patterns and fiber arrangements can be customized to meet specific strength requirements for different automotive applications, ensuring optimal performance in various vehicle parts. This advanced material plays a crucial role in reducing overall vehicle weight while enhancing safety standards and fuel efficiency.