Versatile Manufacturing Capabilities

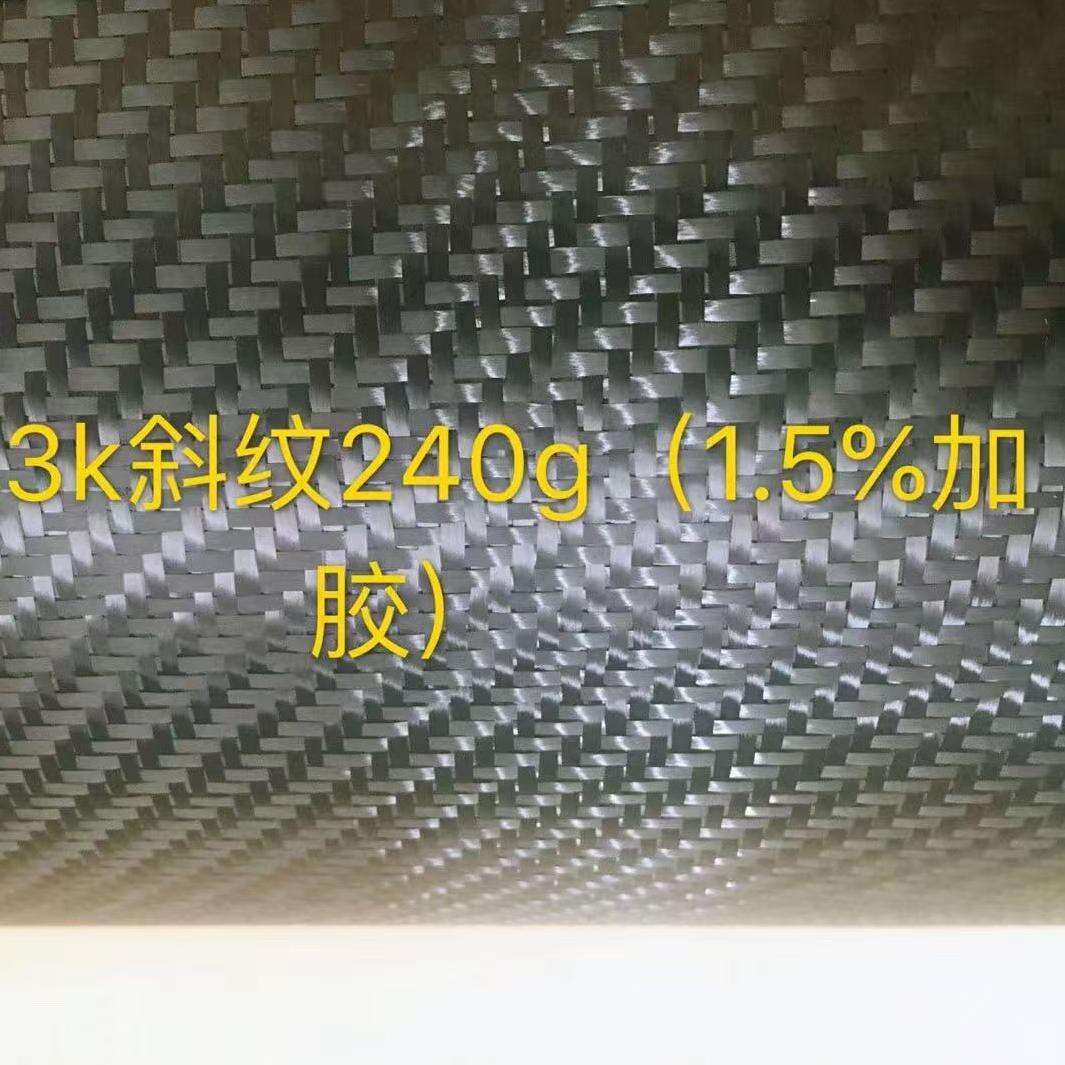

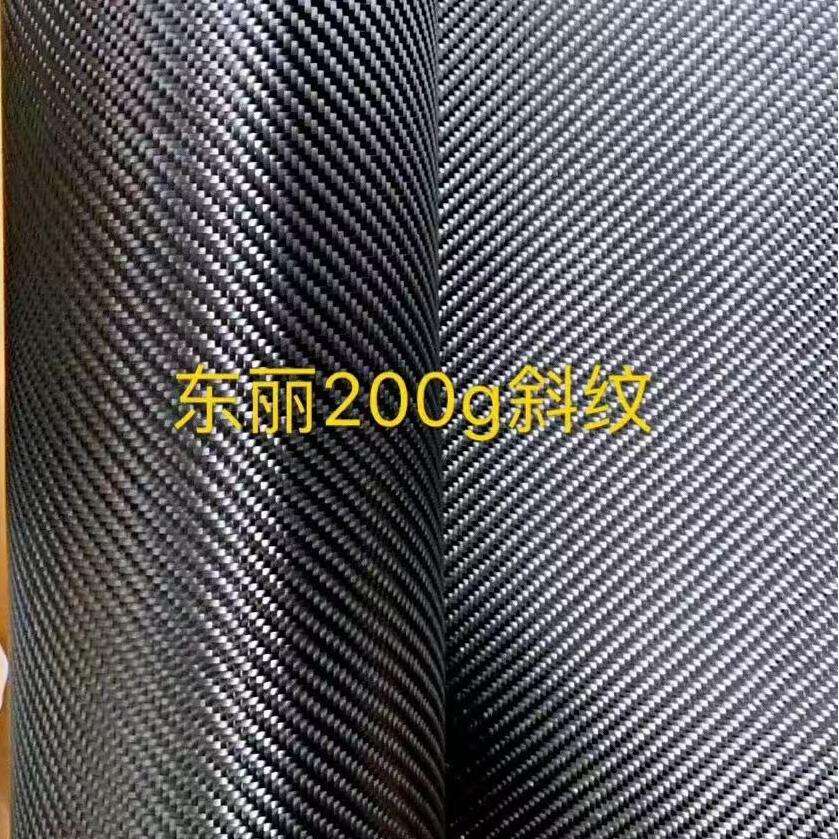

Woven carbon's manufacturing versatility sets it apart in the composite materials landscape. The material can be produced in various weave patterns, including plain, twill, and satin weaves, each offering distinct characteristics suitable for different applications. The manufacturing process allows for precise control over fiber orientation and density, enabling customization of mechanical properties to meet specific requirements. The material's drapability and conformability make it ideal for creating complex shapes and geometries without compromising structural integrity. Advanced manufacturing techniques, such as automated fiber placement and resin transfer molding, can be effectively utilized with woven carbon, ensuring consistent quality and reproducibility in production.