No.80 Changjiang Mingzhu Road, Houcheng Street, Zhangjiagang City, Jiangsu Province, China +86-15995540423 [email protected] +86 15995540423

Carbon fiber is hailed as the "King of New Materials," finding extensive applications in aerospace, automotive manufacturing, sports equipment, and other fields. But did you know? Even within carbon fiber, manufacturing processes can vary dramatically. Today, we'll comprehensively analyze the three key technologies for producing carbon fiber—dry jet-spinning, dry spinning, and wet spinning—and examine how major domestic and international companies select these technologies.

Dry-jet-wet-spinning (The mainstream choice for high-performance carbon fiber)

Definition

Dry-spray wet-spinning, as the name suggests, combines the characteristics of both "dry spinning" and "wet spinning" processes. This technique is primarily used to produce high-performance PAN-based carbon fiber precursors.

Process Flow

(1) Spinning Solution Preparation: Polyacrylonitrile (PAN) is dissolved in a specific solvent to form a viscous spinning solution.

(2) Dry-Spray Stage: The spinning solution is extruded through a spinneret plate and first passes through an air layer (typically several millimeters to centimeters).

(3) Wet-Spinning Stage: The fiber bundle then enters a coagulation bath, where it rapidly solidifies and forms.

(4) Post-Processing: Through steps such as washing, stretching, oiling, and drying, the carbon fiber precursor is ultimately formed.

Technical Advantages

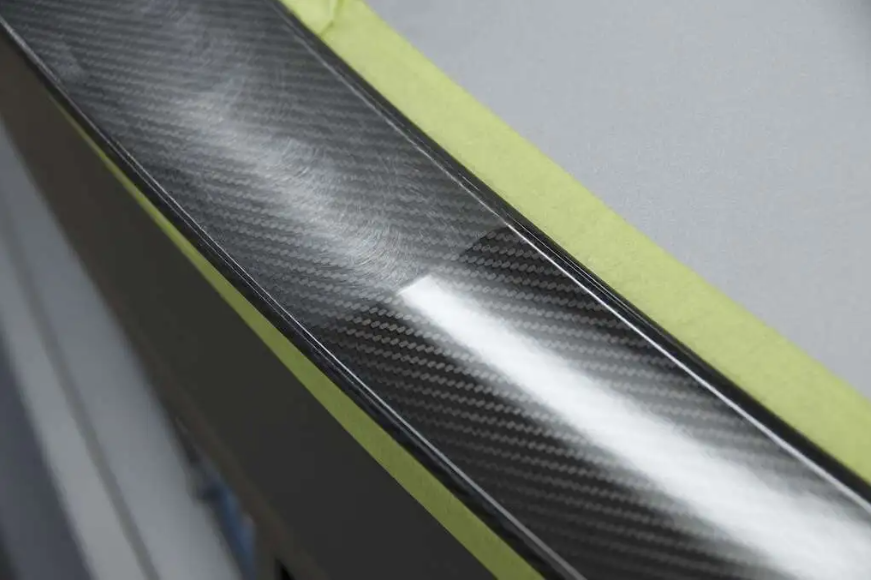

(1) More uniform fiber structure: Tension within the air layer improves molecular chain orientation

(2) Smoother surface: Reduces surface defects, enhancing the mechanical properties of the final carbon fiber

(3) Higher production efficiency: Spinning speed reaches 2-3 times that of wet spinning

(4) Suitable for producing high-performance fibers: Such as T700, T800, and higher-grade carbon fibers

Wet Spinning (Traditional Mature)

Definition

Wet spinning is the earliest method for industrial production of carbon fiber precursors. While technically mature, it has certain limitations.

A polymer is dissolved in a suitable solvent to form a concentrated solution (spinning bath). This solution is then extruded through the micro-pores of a spinneret and directly injected into a solidification bath containing a non-solvent. Within the bath, bidirectional diffusion occurs between the solvent in the spinning stream and the non-solvent in the bath. This causes the polymer to precipitate and solidify, forming primary fibers.

Process Flow

(1) Spinning Solution Preparation: PAN dissolved in solvent (e.g., DMF, DMSO)

(2) Direct Solidification: Spinning solution extruded from spinneret directly into solidification bath

(3) Phase Separation Solidification: Solidification achieved through bidirectional diffusion process

(4) Post-treatment: Washing, stretching, drying, etc.

Technical Characteristics

(1) Limited cross-sectional shapes: Primarily circular or oval

(2) Relatively low spinning speed: Typically 50–150 m/min

(3) Prone to surface defects: Susceptible to surface pores and grooves

(4) Relatively simple equipment: Suitable for producing medium-to-low performance carbon fibers

Dry Spinning (Special Carbon Fiber Selection)

Definition

Dry spinning is another significant method for preparing carbon fiber precursors, particularly utilized in the production of certain specialty carbon fibers.

Dry spinning involves extruding a polymer solution through spinnerets, where the solvent evaporates directly in hot air to form fibers (e.g., spandex production). However, within the carbon fiber industry, it is often mistakenly used as an abbreviation for "dry-spun wet-laid" (DSWL).

Process Flow

(1) Solution Preparation: Dissolve polymer in volatile solvent

(2) Extrusion and Solvent Evaporation: Solution is extruded through a spinneret plate directly into a hot-air-filled spinning tunnel

(3) Solvent Recovery: Evaporated solvent is recovered for reuse

(4) Fiber collection: Fully solidified fibers are wound and collected

Technical Characteristics

(1) Diverse fiber cross-sectional shapes: Capable of producing fibers with irregular cross-sections

(2) Complex solvent recovery system: Requires sophisticated solvent recovery equipment

(3) Suitable for specific polymers: Such as certain modified PAN or other carbon fiber precursor polymers

Comprehensive Comparison Table of Three Major Technologies

Comparison Dimensions |

Dry-spun wet-laid |

Wet spinning |

Dry spinning |

Process Flow |

First air layer stretching, then solidification bath curing |

Directly enter the solidification bath for curing |

Curing by solvent evaporation in hot air |

Spinning speed |

High (200–400 m/min) |

Low (50-150 m/min) |

Moderate |

Fiber Structure |

Dense and uniform, with a smooth surface |

Relatively loose, with a surface prone to defects |

Unique structure, accommodates irregular cross-sections |

Product Performance |

High Performance (T700 and above) |

Low to medium performance |

Special Performance |

Production Cost |

relatively high |

lower |

High (requires solvent recovery) |

Technical Barrier |

High |

Medium |

High |

Primary Applications |

Aerospace, high-end sports equipment |

Industrial sector, general consumer |

Specialized Fields, Specialized Fibers |

Comparison of Major Corporate Technology Roadmaps

Brand |

Primary Technical Approach |

Product Features and Market Positioning |

Industry standing |

Toray |

Dry-Spun Wet-Spun (Comprehensive Leadership) |

Full range of high-performance products (primarily micro-towel) Aerospace-grade premium applications Industry benchmark |

Global Technology Leader |

Zhongfu Shenyang |

Dry-Spun Wet-Spun (Independent Breakthrough) |

Domestic high-performance carbon fiber (primarily small-towel) targeting Toray's T700-T800 grade, primarily serving high-end markets such as aerospace, pressure vessels, and sporting goods. |

Leading domestic manufacturer of high-performance fibers |

Jilin Chemical Fibers Group |

Wet spinning (leading in scale) |

Large-scale fiber bundles, low-cost production, primarily targeting industrial-grade applications (wind turbine blades, automotive lightweighting, structural reinforcement in construction, etc.) |

Global Leader in Massive-Bulk Preform and Carbon Fiber Production Capacity |

Future Development Trends

(1) Optimization of Dry-Spray Wet-Spinning Technology: Advancing toward higher spinning speeds and more stable quality to further reduce the cost of high-performance carbon fibers.

(2) Upgrading Wet Spinning: Enhancing the performance of wet-spun fibers through process improvements to expand application fields.

(3) Process Integration Innovation: Develop novel composite spinning techniques by combining strengths of different processes.

(4) Green Manufacturing: Create eco-friendly solvent systems to reduce environmental impact during production.

The lightweight yet resilient nature of carbon fiber stems from meticulously refined manufacturing processes. From the traditional maturity of wet spinning to the specialized applications of dry spinning, and the high-performance breakthroughs of dry-wet spinning—each technique represents the crystallization of materials scientists' ingenuity.

Understanding these technological distinctions not only explains the wide price variations among carbon fibers but also illuminates the arduous journey and remarkable achievements of China's carbon fiber industry as it transitions from catching up to keeping pace. On the path to becoming a materials powerhouse, every technological breakthrough deserves our attention and applause.

Copyright © 2026 Zhangjiagang Weinuo Composites Co., Ltd. All rights reserved