No.80 Changjiang Mingzhu Road, Houcheng Street, Zhangjiagang City, Jiangsu Province, China +86-15995540423 [email protected] +86 15995540423

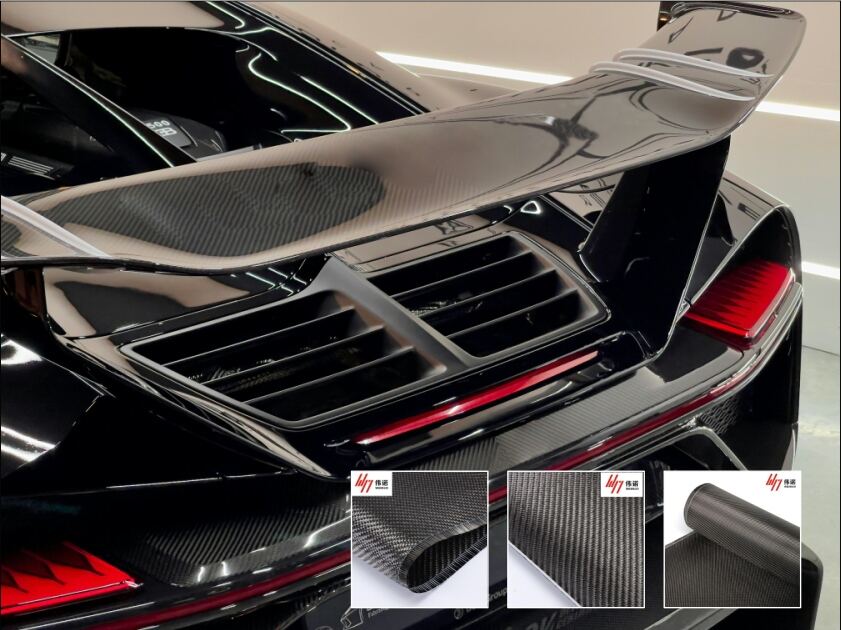

When we see carbon fiber components on top-tier supercars or F1 race cars, we're always captivated by its striking texture and exceptional performance. This material, dubbed "black gold," weighs only one-quarter as much as steel yet boasts 5 to 10 times the strength—theoretically making it the perfect choice for automotive lightweighting.

Yet when we turn our attention to the everyday passenger car market, carbon fiber applications remain scarce. Why is that?

Price: An Insurmountable Gap

"Carbon fiber isn't a material—it's currency," an automotive engineer once quipped.

Currently, carbon fiber composites cost roughly 20 times more than ordinary steel and 10 times more than aluminum. This significant price disparity directly limits carbon fiber's application to high-end vehicles with premium price tags.

Take a mid-sized family sedan as an example: if steel were fully replaced with carbon fiber, material costs would increase by tens of thousands of yuan. This would undoubtedly drive up the vehicle's price significantly, placing it beyond the reach of most consumers.

Manufacturing: The Dual Challenge of Time and Craftsmanship

Unlike traditional metal materials, the manufacturing process for carbon fiber composites is complex and time-consuming:

(1)Long forming time

Carbon fiber components require curing for hours in high-temperature, high-pressure molds, whereas steel parts are stamped into shape in just minutes.

(2)Difficult to repair

Once damaged, carbon fiber components often require complete replacement, whereas metal parts can be repaired through sheet metal work.

(3)Challenging to join

Connecting carbon fiber components requires specialized techniques and cannot be achieved through simple welding like metal.

These manufacturing challenges place carbon fiber at a disadvantage in large-scale automotive production, where efficiency and cost control are paramount.

Recycling Challenges: A Hurdle to Sustainable Development

In today's era of heightened environmental awareness, material recyclability has become a critical consideration for automakers. Recycling carbon fiber composites presents significant challenges:

(1) Difficulty in melting and reusing them like metals

(2) Existing recycling technologies are costly and degrade fiber performance

(3) Specialized resin matrices are typically non-recyclable

In contrast, steel achieves over 90% recycling rates through relatively simple and economical processes.

Redefining Safety Standards

Despite carbon fiber's exceptional strength, its collision safety design differs from traditional metals:

(1) Carbon fiber tends to fracture rather than deform under severe impact.

(2) Its energy absorption characteristics differ from traditional metals, requiring entirely new safety design concepts.

(3) It is not fully compatible with existing safety testing standards and evaluation methods.

Automakers must invest significant resources to re-research and validate the safety of carbon fiber structures, which has delayed its adoption in mainstream vehicle models.

Dawn's First Light: The Possibilities Ahead

Despite numerous challenges, the prospects for carbon fiber applications in the automotive industry are not entirely bleak:

Hybrid Material Bodies: Many automakers are adopting a "multi-material strategy," using carbon fiber in critical areas while retaining traditional materials elsewhere to balance performance and cost.

Technological Advancements: Novel low-cost carbon fiber manufacturing techniques are under development, such as utilizing non-PAN-based precursors and optimizing production processes, which hold promise for significantly reducing carbon fiber costs in the future.

Prioritizing Specific Applications: Battery electric vehicles (BEVs) demand greater weight reduction, as every 10% reduction in weight can increase range by approximately 6-8%. This makes carbon fiber adoption potentially faster in the electric vehicle sector.

The widespread adoption of carbon fiber in the automotive industry is a balancing act between performance, cost, and practicality. It stands as the "luxury item" of automotive materials—possessing unquestionably superior properties yet remaining out of reach for the average consumer due to price, manufacturing complexity, and environmental considerations.

As technology advances and costs decline, carbon fiber may gradually transition from being exclusive to supercars to becoming standard in premium models, ultimately reaching the mass market. However, the timing of this shift remains uncertain.

For consumers, we can anticipate that in the not-too-distant future, vehicles featuring carbon fiber components will no longer be the exclusive domain of million-dollar luxury cars. Instead, they will become a sensible choice for a wider range of models prioritizing performance and energy efficiency.

Copyright © 2026 Zhangjiagang Weinuo Composites Co., Ltd. All rights reserved