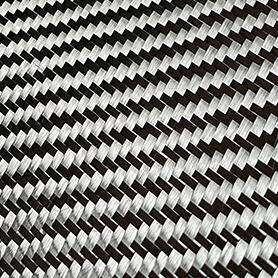

wholesale twill weave carbon fiber

Wholesale twill weave carbon fiber represents a premium grade composite material characterized by its distinctive 2x2 weaving pattern, where each warp fiber passes alternatively over and under two weft fibers. This sophisticated weaving technique creates a diagonal pattern that enhances the material's structural integrity and aesthetic appeal. The material combines high-strength carbon fibers with advanced resin systems, resulting in a composite that offers exceptional mechanical properties. The twill weave pattern provides superior draping capability, making it ideal for complex curved surfaces and intricate manufacturing processes. These carbon fiber sheets typically come in various weights, ranging from 200gsm to 400gsm, catering to different industrial applications. The material exhibits remarkable tensile strength, with values often exceeding 3000 MPa, while maintaining a significantly lower weight compared to traditional materials like steel or aluminum. Its excellent fatigue resistance and dimensional stability make it particularly valuable in high-performance applications where weight reduction and structural integrity are crucial.