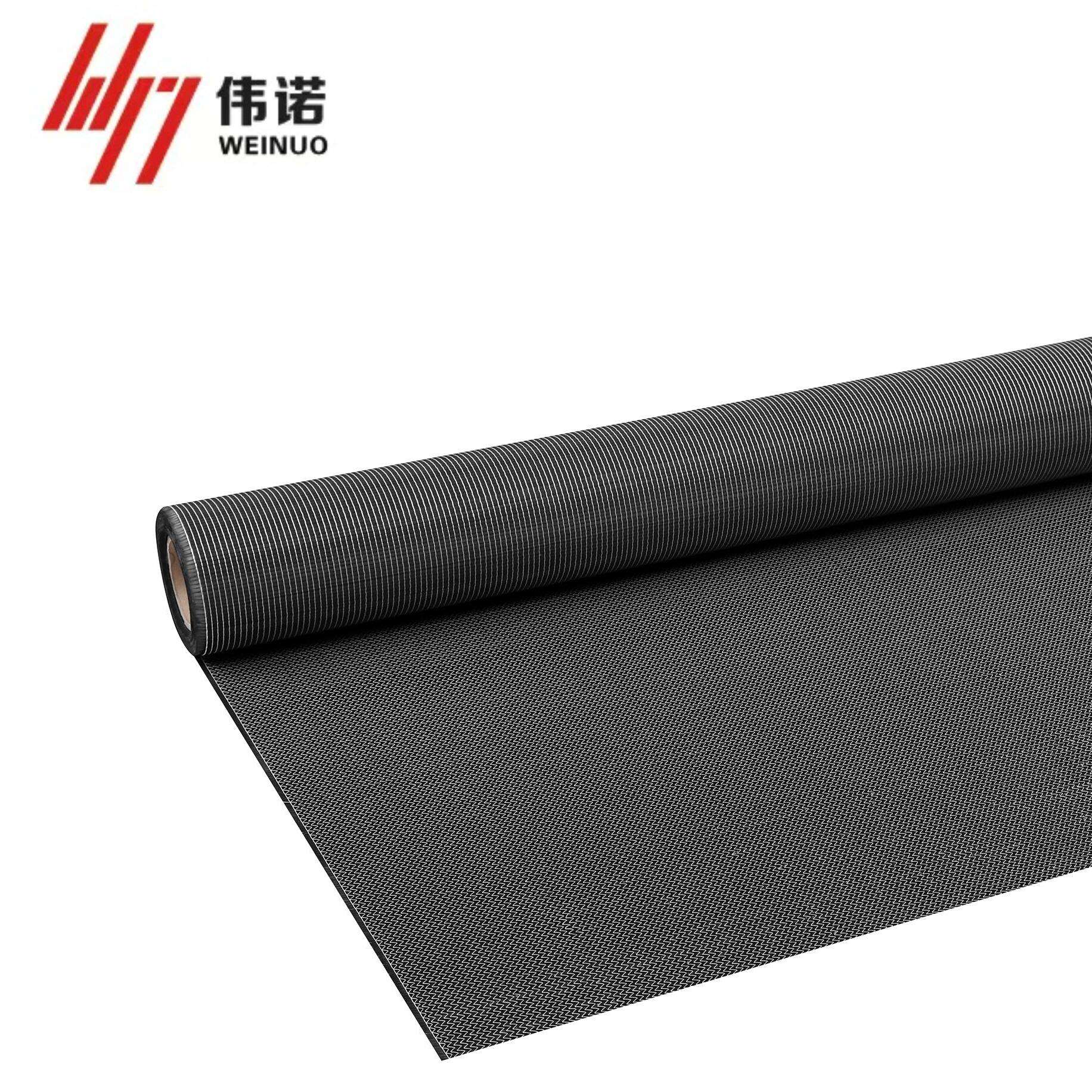

woven carbon fiber cloth

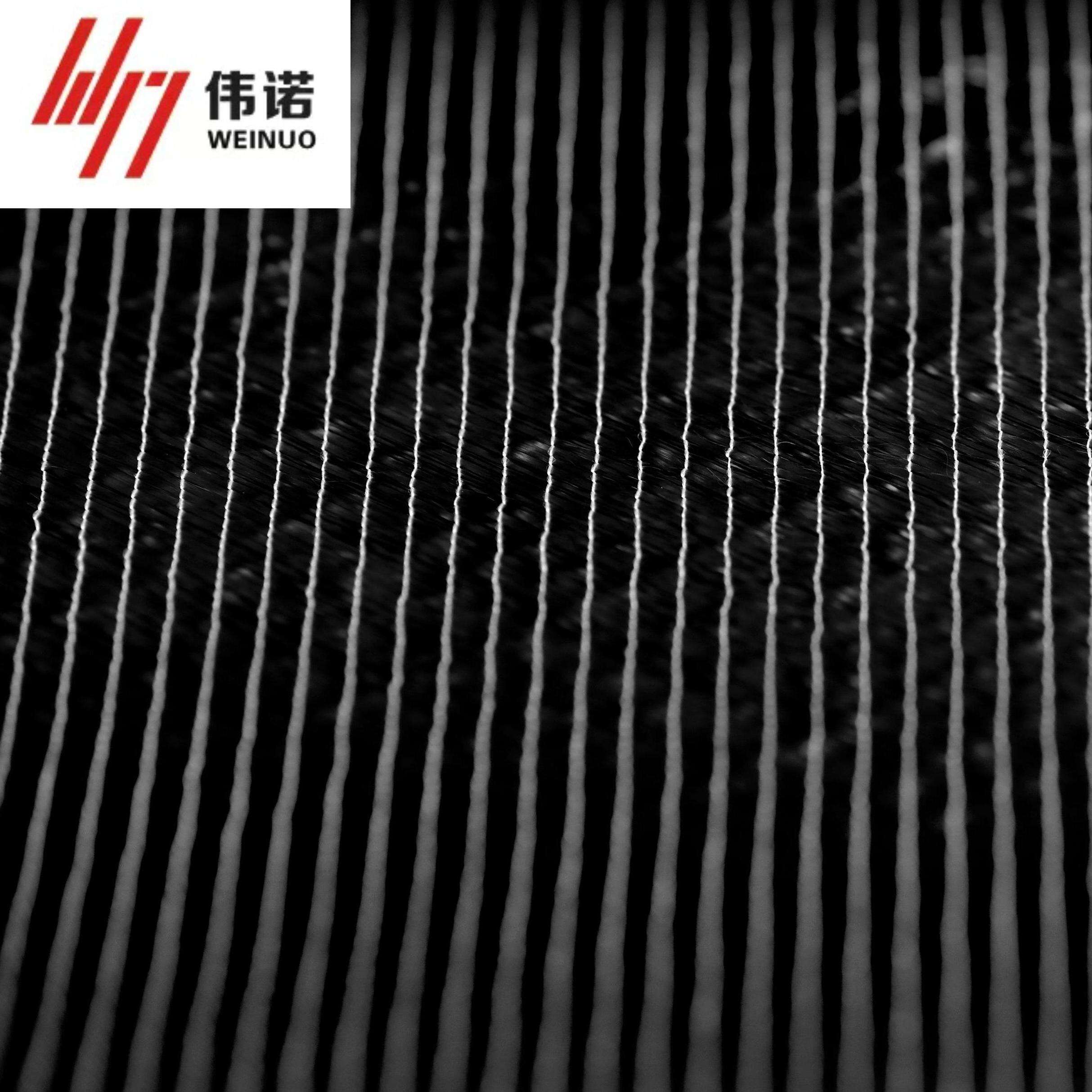

Woven carbon fiber cloth represents a revolutionary advancement in composite materials, combining exceptional strength with remarkably low weight. This innovative material consists of carbon fibers meticulously woven into a precise pattern, creating a fabric-like structure that delivers outstanding mechanical properties. The manufacturing process involves carefully aligning thousands of carbon filaments, each thinner than a human hair, into a distinctive weave pattern that maximizes strength in multiple directions. The resulting material offers an impressive strength-to-weight ratio that surpasses traditional materials like steel and aluminum. The cloth's versatility allows it to be impregnated with various resins to create composite parts that maintain structural integrity under extreme conditions. Its unique properties include excellent fatigue resistance, high temperature tolerance, and superior dimensional stability. The material finds extensive applications across numerous industries, from aerospace and automotive manufacturing to sporting goods and high-performance equipment. The cloth's adaptability allows it to be molded into complex shapes while maintaining its structural properties, making it ideal for both structural and aesthetic applications. Modern manufacturing techniques have made woven carbon fiber cloth increasingly accessible for both industrial and consumer applications, revolutionizing product design and engineering capabilities.