durable twill weave carbon fiber

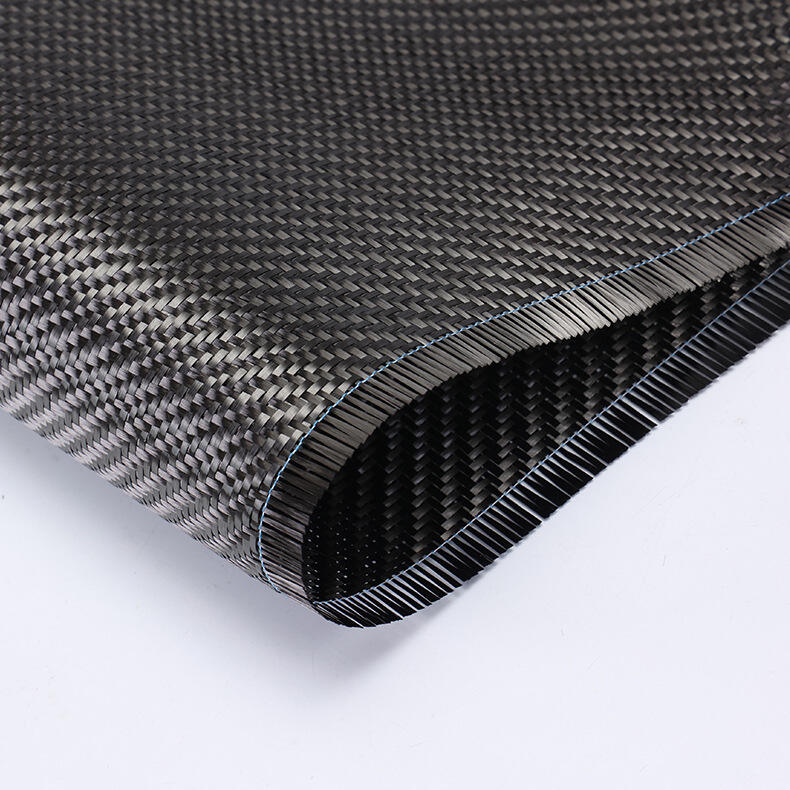

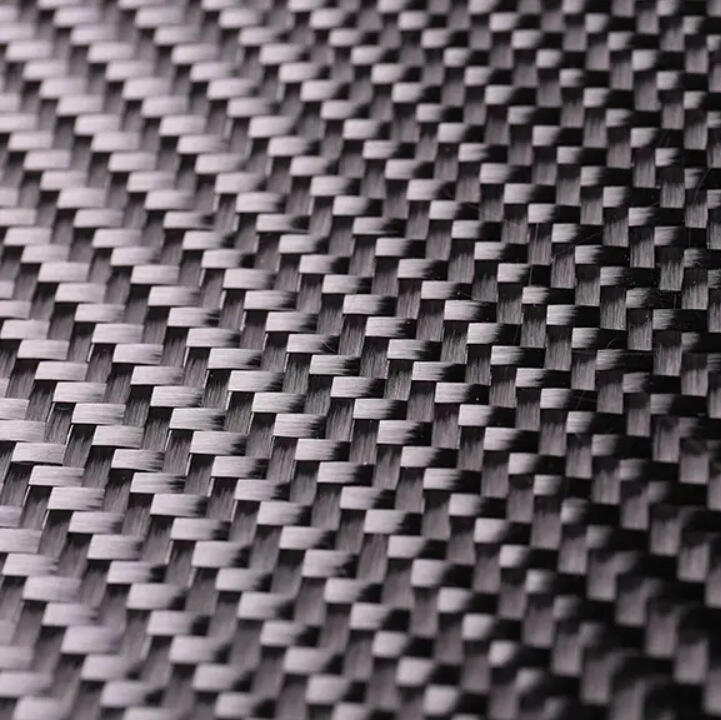

Durable twill weave carbon fiber represents a sophisticated advancement in composite material technology, combining strength, aesthetics, and versatility in one remarkable package. This specialized weave pattern creates a distinctive diagonal rib design that not only enhances the material's visual appeal but also contributes to its exceptional structural integrity. The twill weave configuration allows carbon fiber strands to interlace in a way that distributes force more evenly across the surface, resulting in superior impact resistance and durability compared to standard weave patterns. The material's construction involves carefully overlapping carbon fiber threads in a 2x2 pattern, where each weft fiber passes over two warp fibers before going under the next two, creating a characteristic diagonal pattern. This specific weaving technique results in a material that's not only incredibly strong but also more pliable during the manufacturing process, making it ideal for complex shapes and curved surfaces. The durability of twill weave carbon fiber is further enhanced by its resistance to environmental factors, including UV radiation, temperature fluctuations, and chemical exposure, ensuring long-term performance in demanding applications.