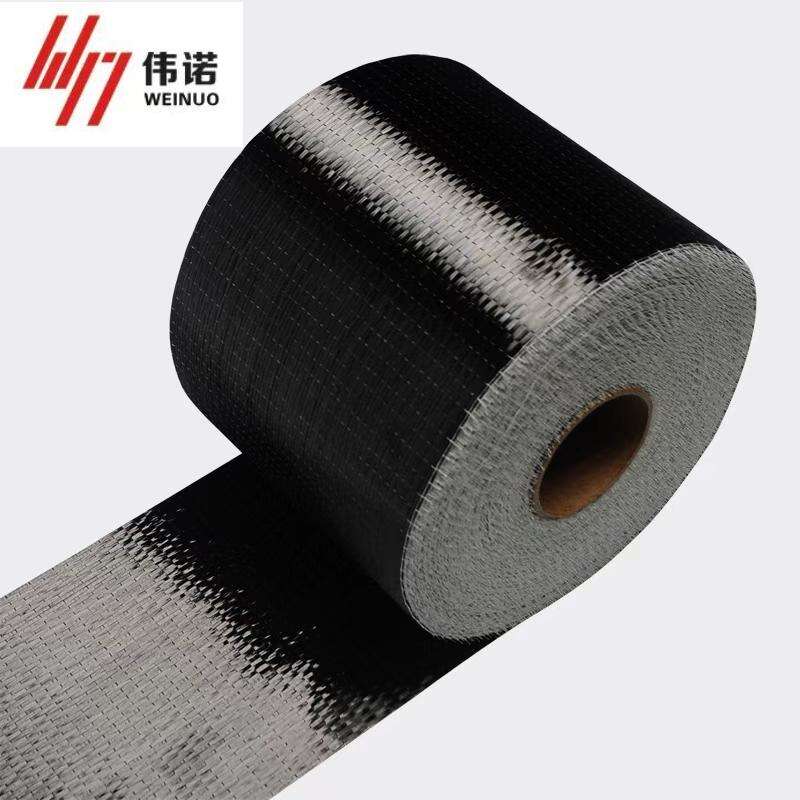

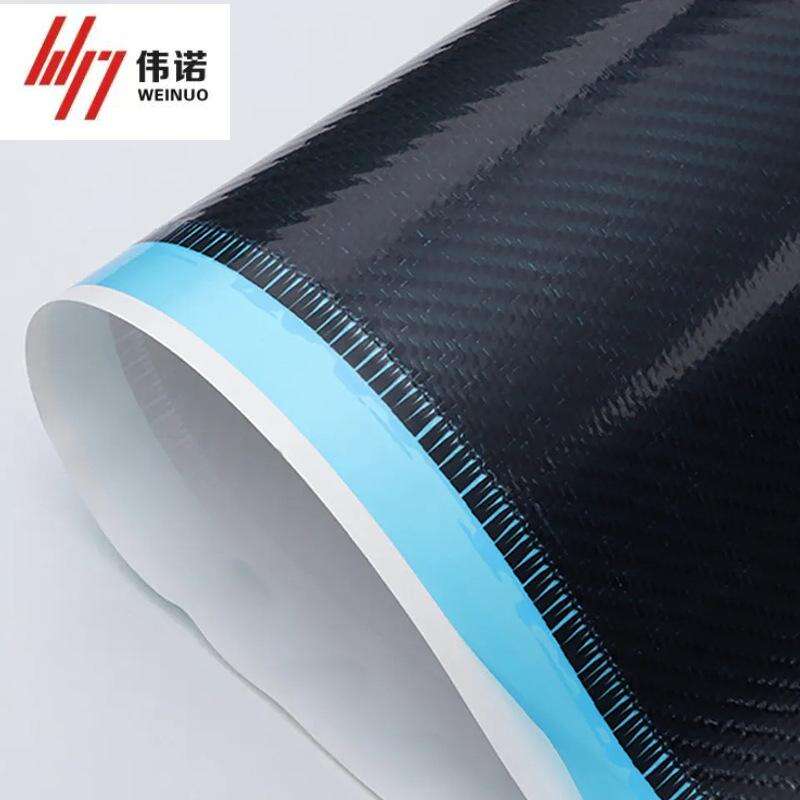

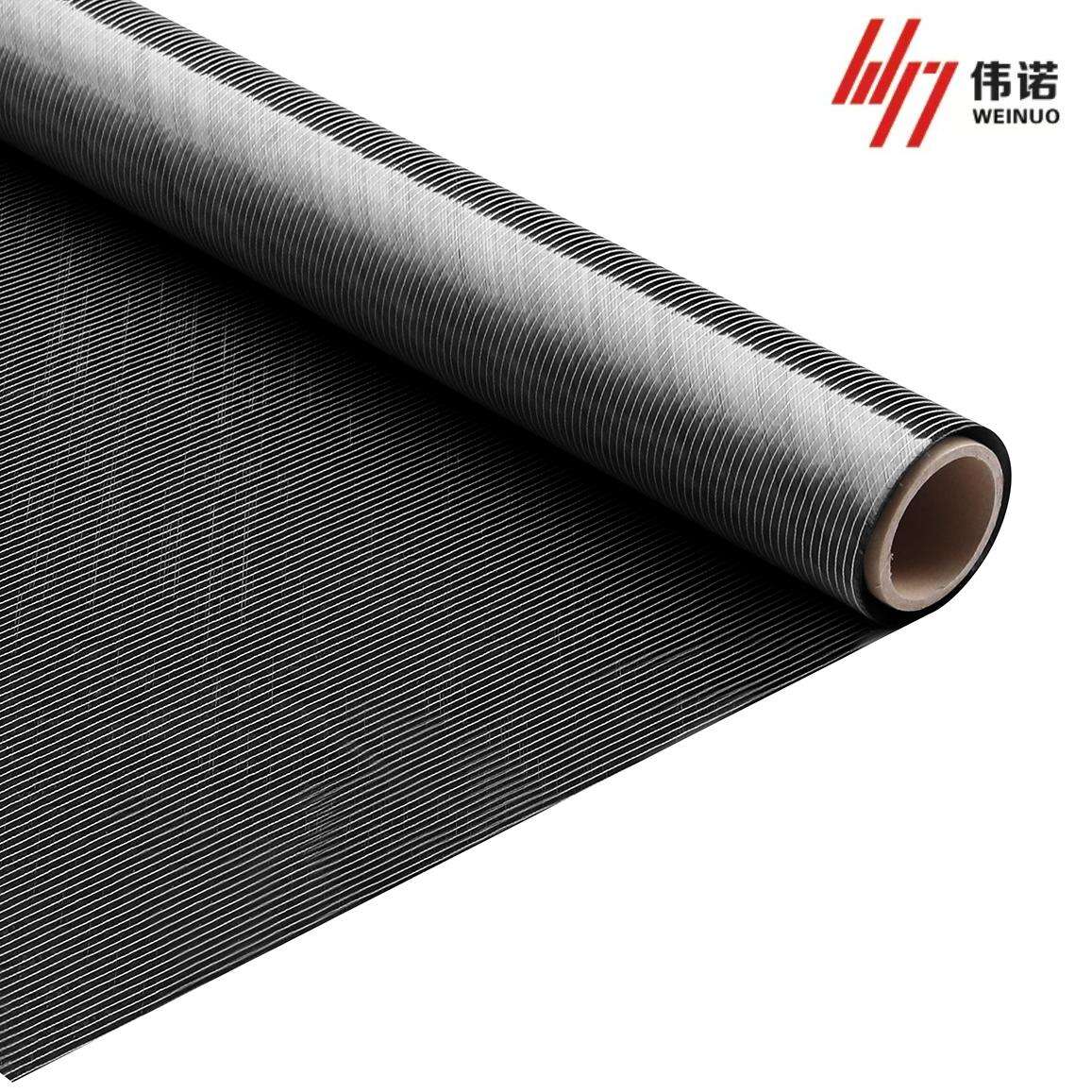

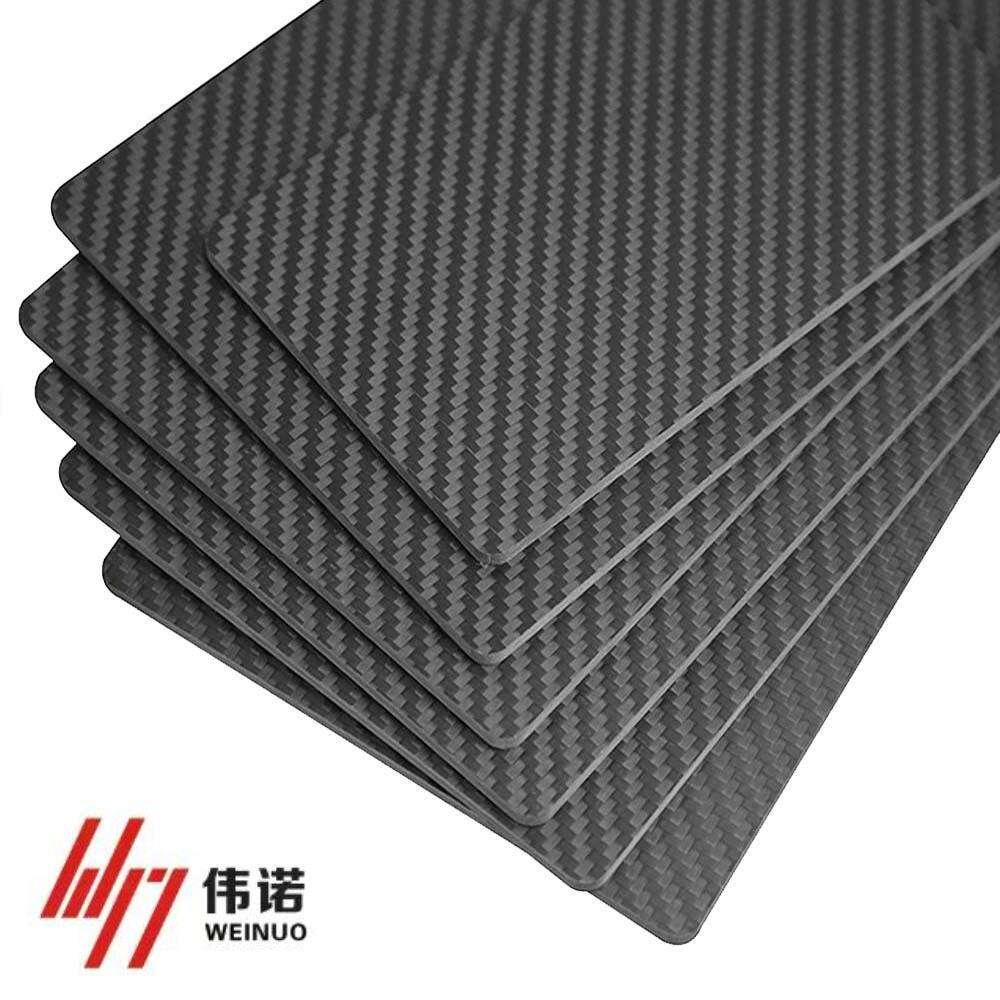

prepreg carbon fiber material

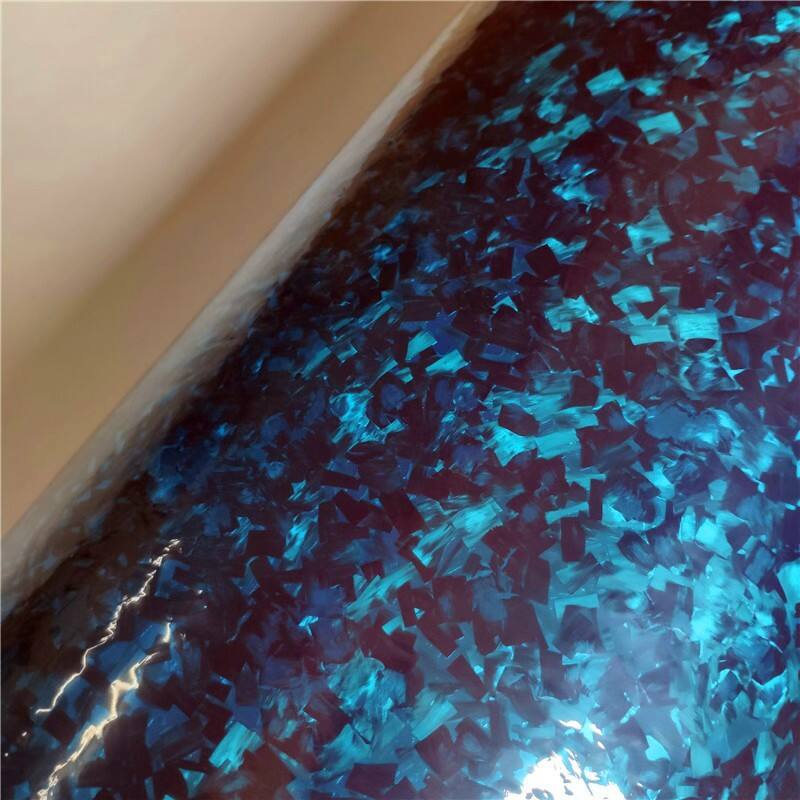

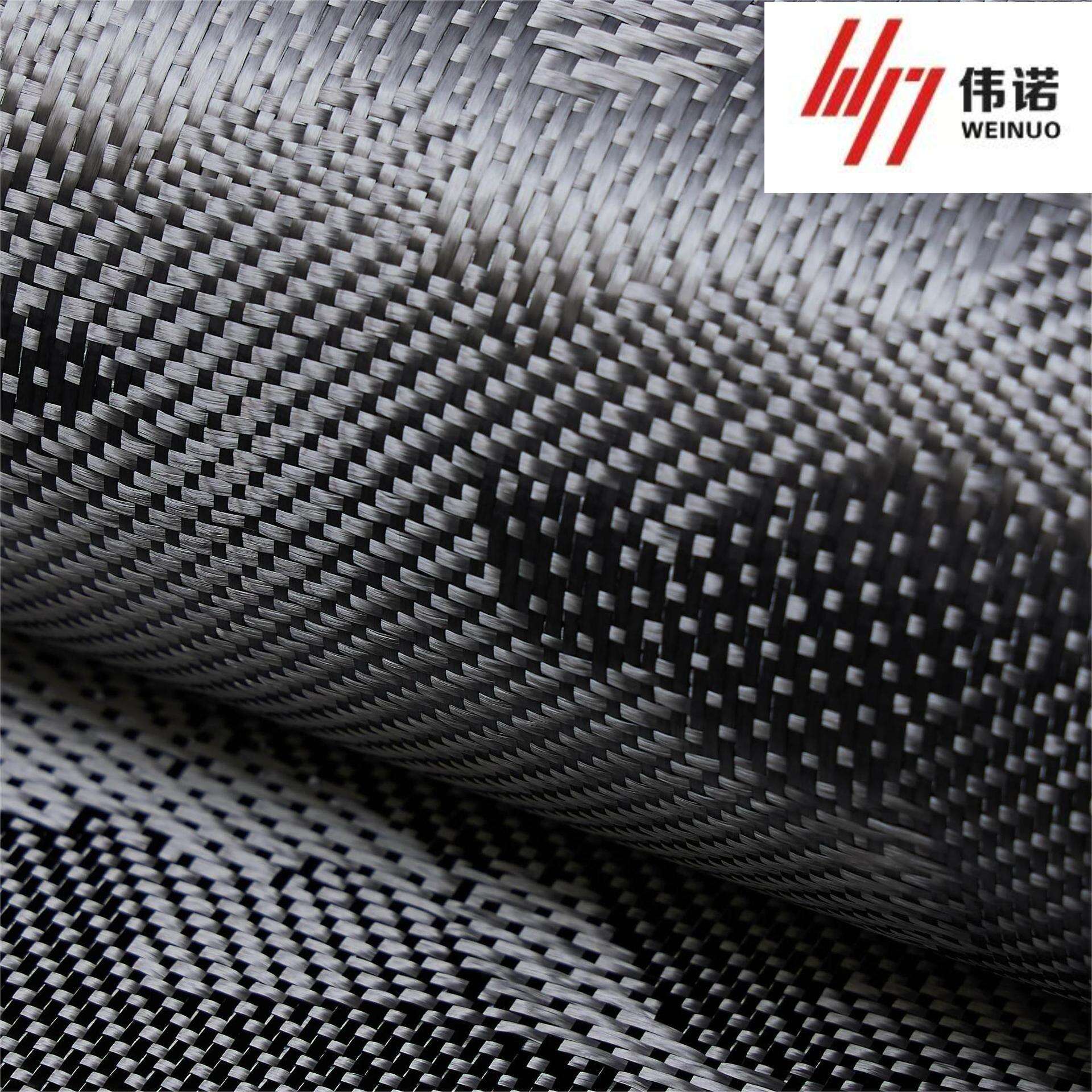

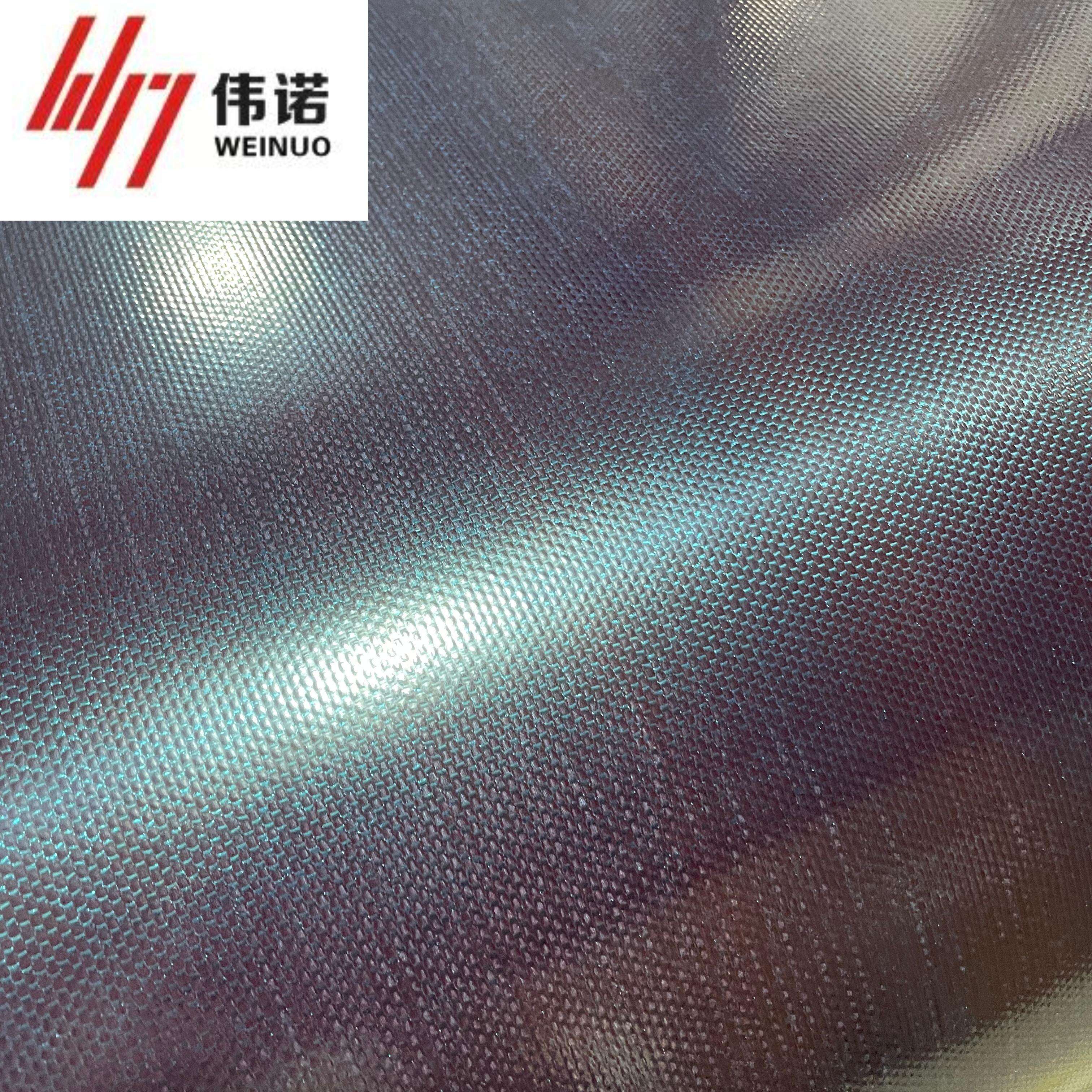

Prepreg carbon fiber material represents a cutting-edge advancement in composite technology, combining high-strength carbon fibers with pre-impregnated resin systems. This sophisticated material consists of carefully aligned carbon fibers that have been pre-impregnated with a precisely measured amount of thermosetting resin, creating a ready-to-use composite that delivers exceptional performance characteristics. The material undergoes a controlled manufacturing process where the resin content, fiber alignment, and material thickness are meticulously regulated to ensure consistent quality. When exposed to heat and pressure during the curing process, the resin system activates, creating an incredibly strong and lightweight composite structure. The material finds extensive applications across various industries, including aerospace, automotive manufacturing, sporting goods, and high-performance equipment production. Its ability to be molded into complex shapes while maintaining structural integrity makes it invaluable for components that require both strength and weight reduction. The material's controlled fiber-to-resin ratio ensures optimal mechanical properties, while its pre-impregnated nature significantly reduces manufacturing complexity and potential errors in the composite layup process.