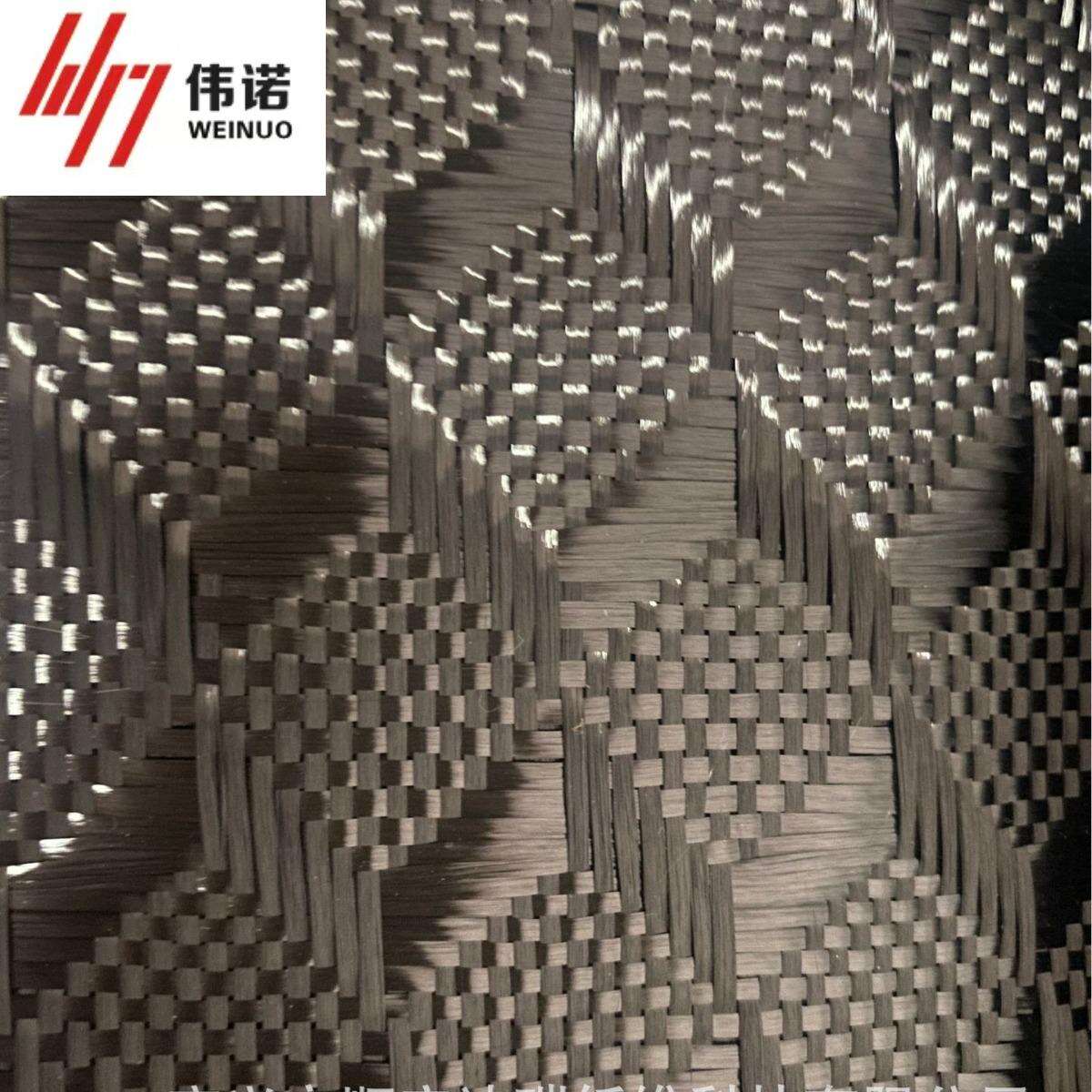

carbon fiber fabric tape

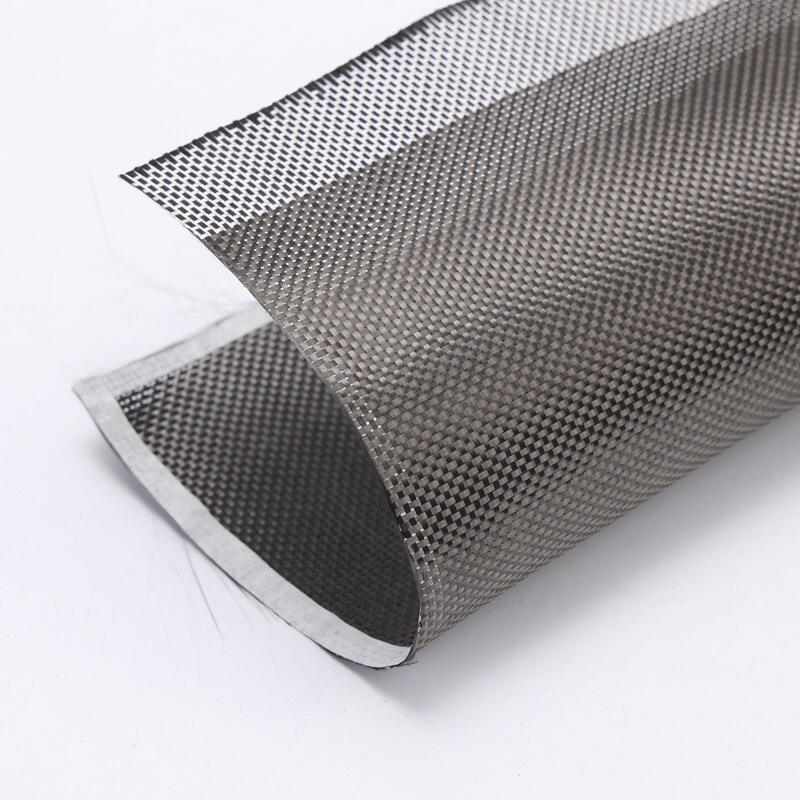

Carbon fiber fabric tape represents a revolutionary advancement in composite materials technology, combining the exceptional strength of carbon fibers with the convenience of a tape format. This versatile material consists of carefully aligned carbon fiber strands woven into a flexible fabric backing, creating a product that offers unprecedented strength-to-weight ratios. The tape features a specialized adhesive system that enables strong bonding to various substrates, making it ideal for both structural reinforcement and repair applications. The material's unique construction allows for easy handling and application while maintaining the remarkable properties of carbon fiber, including high tensile strength, excellent fatigue resistance, and dimensional stability. Available in various widths and thicknesses, carbon fiber fabric tape can be precisely tailored to specific application requirements. The material exhibits outstanding resistance to environmental factors, including UV exposure, temperature fluctuations, and chemical exposure, ensuring long-term durability. Its ability to conform to complex geometries while maintaining structural integrity makes it particularly valuable in aerospace, automotive, and industrial applications where weight reduction and strength enhancement are crucial considerations.