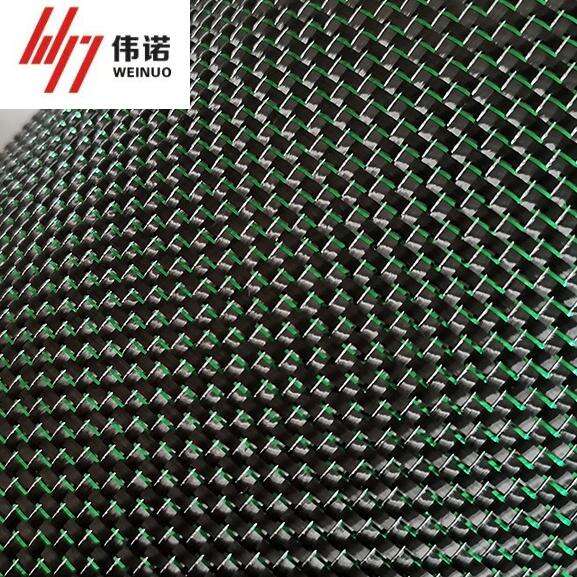

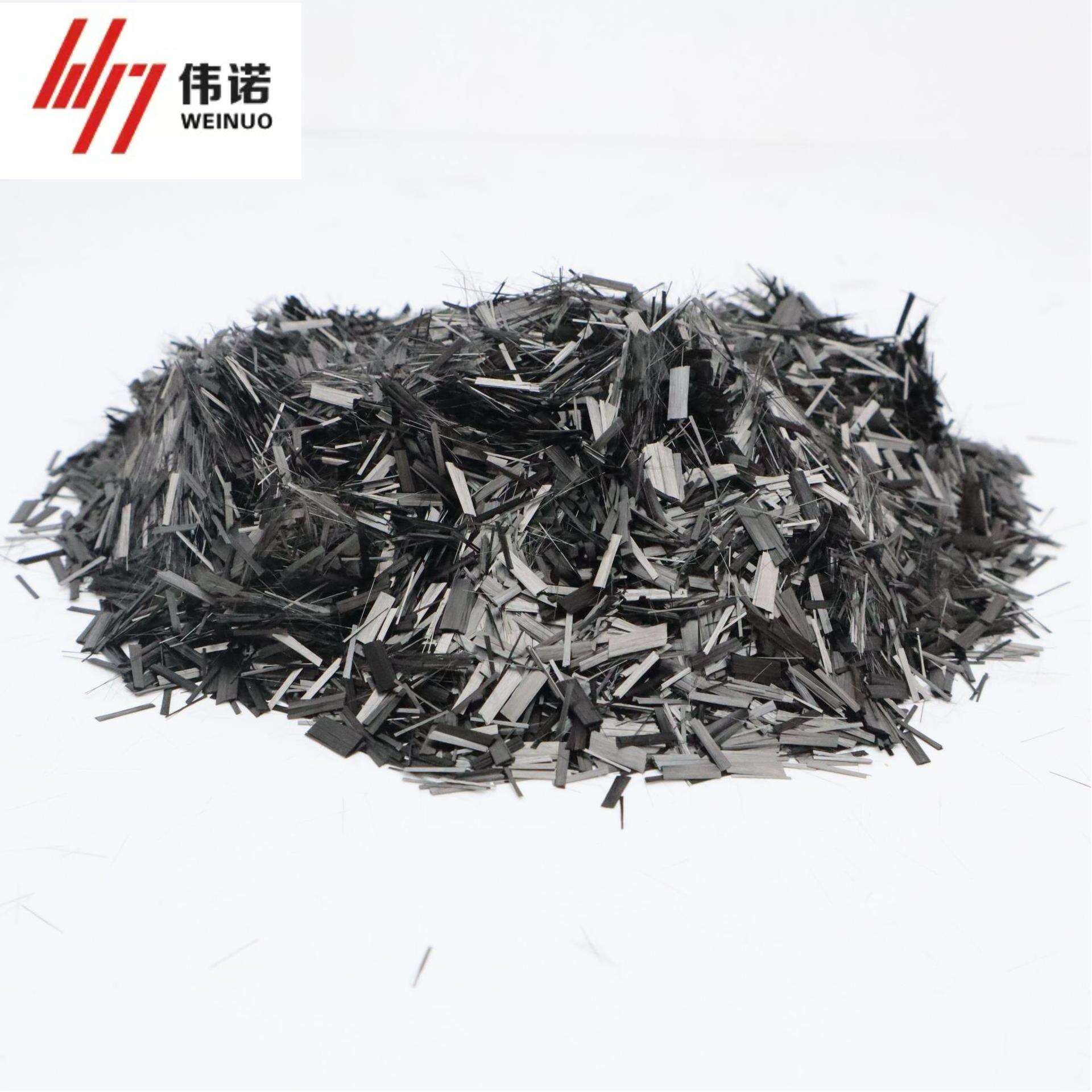

The manufacturing industry has witnessed a remarkable transformation with the integration of advanced composite materials, particularly chopped carbon fiber, which has emerged as a game-changing solution for numerous industrial applications. This versatile material combines the exceptional strength-to-weight ratio of carbon fiber with enhanced processability, making it an ideal choice for manufacturers seeking to improve product performance while reducing overall weight. Chopped carbon fiber offers unique advantages that traditional materials simply cannot match, enabling industries to push the boundaries of innovation and efficiency.

Automotive Industry Applications

Lightweight Structural Components

The automotive sector has embraced chopped carbon fiber as a critical material for developing lightweight structural components that meet stringent safety and performance requirements. Modern vehicles incorporate this material in various applications, from reinforcing plastic parts to creating composite panels that significantly reduce vehicle weight. The integration of chopped carbon fiber in automotive manufacturing processes has enabled manufacturers to achieve fuel efficiency targets while maintaining structural integrity and crashworthiness standards.

Manufacturing processes utilizing chopped carbon fiber in automotive applications include injection molding, compression molding, and resin transfer molding techniques. These methods allow for the production of complex geometries that would be challenging or impossible to achieve with traditional materials. The random orientation of chopped carbon fiber provides multidirectional strength characteristics, making it particularly suitable for components that experience loads from multiple directions during vehicle operation.

Interior and Exterior Trim Elements

Automotive interior and exterior trim applications have significantly benefited from the aesthetic and functional properties of chopped carbon fiber composites. Dashboard components, door panels, and decorative elements manufactured with this material offer superior durability and dimensional stability compared to conventional plastic alternatives. The material's ability to maintain its properties under varying temperature and humidity conditions makes it particularly valuable for automotive applications where environmental resistance is crucial.

The surface finish quality achievable with chopped carbon fiber composites has opened new possibilities for premium automotive applications. Manufacturers can create parts with excellent surface smoothness and consistent appearance, eliminating the need for extensive post-processing operations. This efficiency in manufacturing translates to cost savings and improved production throughput, making chopped carbon fiber an economically viable option for high-volume automotive production.

Aerospace and Aviation Applications

Secondary Structural Components

The aerospace industry has recognized the exceptional value of chopped carbon fiber in manufacturing secondary structural components that require high strength-to-weight ratios and excellent fatigue resistance. Aircraft interior panels, equipment housings, and non-critical structural elements benefit significantly from the weight reduction achievable with chopped carbon fiber composites. These applications contribute to overall aircraft efficiency by reducing fuel consumption and increasing payload capacity.

Aerospace manufacturers utilize specialized processing techniques to maximize the performance characteristics of chopped carbon fiber in their applications. The material's excellent dimensional stability under temperature variations makes it particularly suitable for aircraft components that experience significant thermal cycling during flight operations. Additionally, the inherent flame resistance properties of carbon fiber composites align with stringent aerospace safety requirements.

Electronic Equipment Housings

Modern aircraft rely heavily on sophisticated electronic systems, and chopped carbon fiber has become instrumental in creating lightweight yet robust housings for these critical components. The material's electromagnetic interference shielding properties, combined with its structural capabilities, make it an ideal choice for protecting sensitive avionics equipment. These housings must withstand significant mechanical stresses while maintaining precise dimensional tolerances throughout the aircraft's operational life.

The manufacturing of electronic equipment housings using chopped carbon fiber involves precision molding techniques that ensure consistent wall thickness and optimal fiber distribution. This attention to manufacturing detail results in components that deliver reliable performance under the demanding conditions encountered in aerospace applications. The ability to integrate complex geometries and mounting features directly into the molded parts reduces assembly complexity and improves overall system reliability.

Industrial Equipment Manufacturing

Machine Tool Components

Industrial machinery manufacturers have discovered significant advantages in incorporating chopped carbon fiber into machine tool components where weight reduction and vibration damping are critical performance factors. Structural frames, covers, and housings manufactured with this material demonstrate superior stiffness-to-weight ratios compared to traditional metal alternatives. The enhanced vibration damping characteristics of chopped carbon fiber composites contribute to improved machining accuracy and reduced tool wear in precision manufacturing applications.

The corrosion resistance properties of chopped carbon fiber make it particularly valuable for machine tools operating in challenging industrial environments. Unlike metal components that may require protective coatings or frequent maintenance to prevent corrosion, carbon fiber composites maintain their structural properties and appearance over extended periods. This durability translates to reduced maintenance costs and improved equipment uptime, providing significant economic benefits to industrial operators.

Conveyor System Elements

Material handling systems across various industries have benefited from the integration of chopped carbon fiber in conveyor components and related equipment. Conveyor frames, guards, and support structures manufactured with this material offer excellent strength while significantly reducing the overall system weight. This weight reduction is particularly advantageous in applications where conveyor systems must be frequently relocated or where structural loading constraints limit the use of heavier traditional materials.

The chemical resistance properties of chopped carbon fiber composites make them suitable for conveyor applications in chemically aggressive environments. Food processing, pharmaceutical manufacturing, and chemical production facilities utilize these materials to create conveyor systems that can withstand exposure to various substances without degradation. The non-porous surface characteristics of properly manufactured carbon fiber composites also facilitate easy cleaning and sanitization in hygiene-critical applications.

Electronics and Consumer Products

Electronic Device Enclosures

The consumer electronics industry has embraced chopped carbon fiber for manufacturing device enclosures that require lightweight construction without compromising durability or electromagnetic shielding performance. Laptop computers, tablets, and professional equipment housings benefit from the exceptional strength characteristics and aesthetic appeal of carbon fiber composites. The material's ability to be molded into complex shapes enables designers to create innovative product forms while maintaining structural integrity.

Manufacturing processes for electronic device enclosures utilizing chopped carbon fiber have been refined to achieve the tight tolerances required for modern consumer products. The dimensional stability of these composites ensures that electronic components fit precisely within their housings throughout the product lifecycle. Additionally, the thermal management properties of carbon fiber help dissipate heat generated by electronic components, contributing to improved device reliability and performance.

Sporting Goods Applications

Sporting goods manufacturers have leveraged the performance advantages of chopped carbon fiber in developing equipment that demands high strength, low weight, and excellent impact resistance. Tennis rackets, golf club components, and protective equipment incorporate this material to enhance performance while reducing user fatigue. The ability to tailor the mechanical properties of chopped carbon fiber composites through fiber orientation and resin selection allows manufacturers to optimize products for specific performance requirements.

The manufacturing flexibility offered by chopped carbon fiber enables sporting goods companies to produce complex geometries that would be difficult or impossible to achieve with traditional materials. This design freedom has led to innovative product configurations that improve functionality and user experience. The excellent fatigue resistance of carbon fiber composites ensures that sporting goods maintain their performance characteristics through extended use cycles, providing superior value to consumers.

Construction and Infrastructure Applications

Architectural Elements

Modern architecture has embraced chopped carbon fiber as a material for creating innovative structural and decorative elements that combine aesthetic appeal with exceptional performance characteristics. Building facades, decorative panels, and architectural features manufactured with this material offer design flexibility while providing long-term durability and weather resistance. The lightweight nature of chopped carbon fiber composites reduces structural loading requirements, enabling architects to create bold designs that would be impractical with heavier traditional materials.

The construction industry benefits from the corrosion resistance and low maintenance requirements of chopped carbon fiber applications. Building components manufactured with these materials maintain their appearance and structural properties for decades without requiring protective coatings or frequent maintenance interventions. This long-term durability provides significant lifecycle cost advantages, making chopped carbon fiber an economically attractive option for high-performance building applications.

Infrastructure Reinforcement

Infrastructure rehabilitation and strengthening projects increasingly utilize chopped carbon fiber composites to extend the service life of existing structures while minimizing added weight and disruption during installation. Bridge components, tunnel linings, and repair patches manufactured with this material provide excellent structural reinforcement with minimal impact on existing structural systems. The ability to create custom-shaped reinforcement elements enables engineers to address specific structural deficiencies effectively.

The installation advantages of chopped carbon fiber infrastructure applications include reduced equipment requirements and shorter installation times compared to traditional reinforcement methods. These composites can be applied using conventional construction techniques while providing superior performance characteristics. The chemical resistance of carbon fiber composites makes them particularly suitable for infrastructure applications in aggressive environments where traditional materials may deteriorate rapidly.

Manufacturing Process Advantages

Processing Efficiency

Manufacturing operations utilizing chopped carbon fiber benefit from streamlined processing techniques that reduce production time and improve quality consistency. The material's compatibility with automated manufacturing systems enables high-volume production while maintaining precise control over fiber distribution and part quality. Injection molding processes incorporating chopped carbon fiber can achieve cycle times comparable to conventional thermoplastics while delivering significantly enhanced mechanical properties.

Quality control systems for chopped carbon fiber manufacturing processes have been developed to ensure consistent part performance across production runs. Non-destructive testing methods can verify fiber distribution and detect potential defects without compromising part integrity. These quality assurance capabilities enable manufacturers to maintain strict performance standards while achieving efficient production throughput rates.

Cost-Effectiveness Analysis

Economic analysis of chopped carbon fiber applications reveals significant cost advantages when considering total lifecycle costs rather than initial material expenses. The reduced weight of components manufactured with this material translates to lower transportation costs, easier handling during assembly, and reduced structural support requirements in final applications. These indirect cost benefits often offset the higher initial material costs, resulting in favorable economic outcomes for manufacturers and end users.

Manufacturing efficiency improvements achieved through the use of chopped carbon fiber contribute to overall cost-effectiveness in industrial applications. The ability to consolidate multiple parts into single molded components reduces assembly time and eliminates potential failure points associated with mechanical fasteners. This part consolidation capability provides both cost savings and improved product reliability, making chopped carbon fiber an attractive option for competitive manufacturing environments.

FAQ

What are the primary advantages of using chopped carbon fiber in industrial applications

Chopped carbon fiber offers exceptional strength-to-weight ratios, excellent dimensional stability, and superior corrosion resistance compared to traditional materials. These properties make it ideal for applications requiring lightweight yet durable components. The material also provides electromagnetic interference shielding, vibration damping characteristics, and the ability to be processed using conventional manufacturing techniques while delivering enhanced performance.

How does chopped carbon fiber compare to continuous fiber reinforcement in terms of performance

While continuous fiber reinforcement provides directional strength advantages, chopped carbon fiber offers multidirectional strength characteristics that are beneficial for components experiencing loads from multiple directions. The random fiber orientation in chopped carbon fiber composites provides more isotropic properties, making it suitable for complex geometries and applications where load directions may vary during operation.

What manufacturing processes are most suitable for chopped carbon fiber applications

Injection molding, compression molding, and resin transfer molding are the most commonly used processes for chopped carbon fiber applications. These techniques allow for high-volume production while maintaining consistent quality and enabling the creation of complex part geometries. The choice of manufacturing process depends on part requirements, production volume, and desired surface finish characteristics.

Are there any limitations or considerations when using chopped carbon fiber in industrial applications

Key considerations include proper handling procedures to avoid skin irritation from carbon fibers, appropriate disposal methods for manufacturing waste, and compatibility with specific resin systems. Additionally, electrical conductivity properties of carbon fiber may require special considerations in electronic applications. Proper training and safety protocols are essential for personnel working with chopped carbon fiber materials to ensure safe and effective utilization.

Table of Contents

- Automotive Industry Applications

- Aerospace and Aviation Applications

- Industrial Equipment Manufacturing

- Electronics and Consumer Products

- Construction and Infrastructure Applications

- Manufacturing Process Advantages

-

FAQ

- What are the primary advantages of using chopped carbon fiber in industrial applications

- How does chopped carbon fiber compare to continuous fiber reinforcement in terms of performance

- What manufacturing processes are most suitable for chopped carbon fiber applications

- Are there any limitations or considerations when using chopped carbon fiber in industrial applications