Carbon fiber reinforcement has revolutionized modern manufacturing across industries, from aerospace to automotive applications. Among the various forms of carbon fiber materials available, understanding the fundamental differences between chopped carbon fiber and continuous fiber systems remains crucial for engineers and designers. The selection between these two primary reinforcement types directly impacts product performance, manufacturing processes, and overall project costs. This comprehensive analysis explores the critical performance differences that influence material selection decisions in today's competitive industrial landscape.

Structural Performance Characteristics

Mechanical Strength Properties

The mechanical strength differences between chopped carbon fiber and continuous fiber systems represent perhaps the most significant performance distinction. Continuous carbon fiber maintains uninterrupted load paths throughout the composite structure, enabling superior tensile strength capabilities that often exceed 3,500 MPa in high-performance applications. This structural continuity allows stress transfer across the entire fiber length, maximizing the material's inherent strength properties. The oriented fiber arrangement in continuous systems also provides predictable directional strength characteristics that engineers can leverage for specific load requirements.

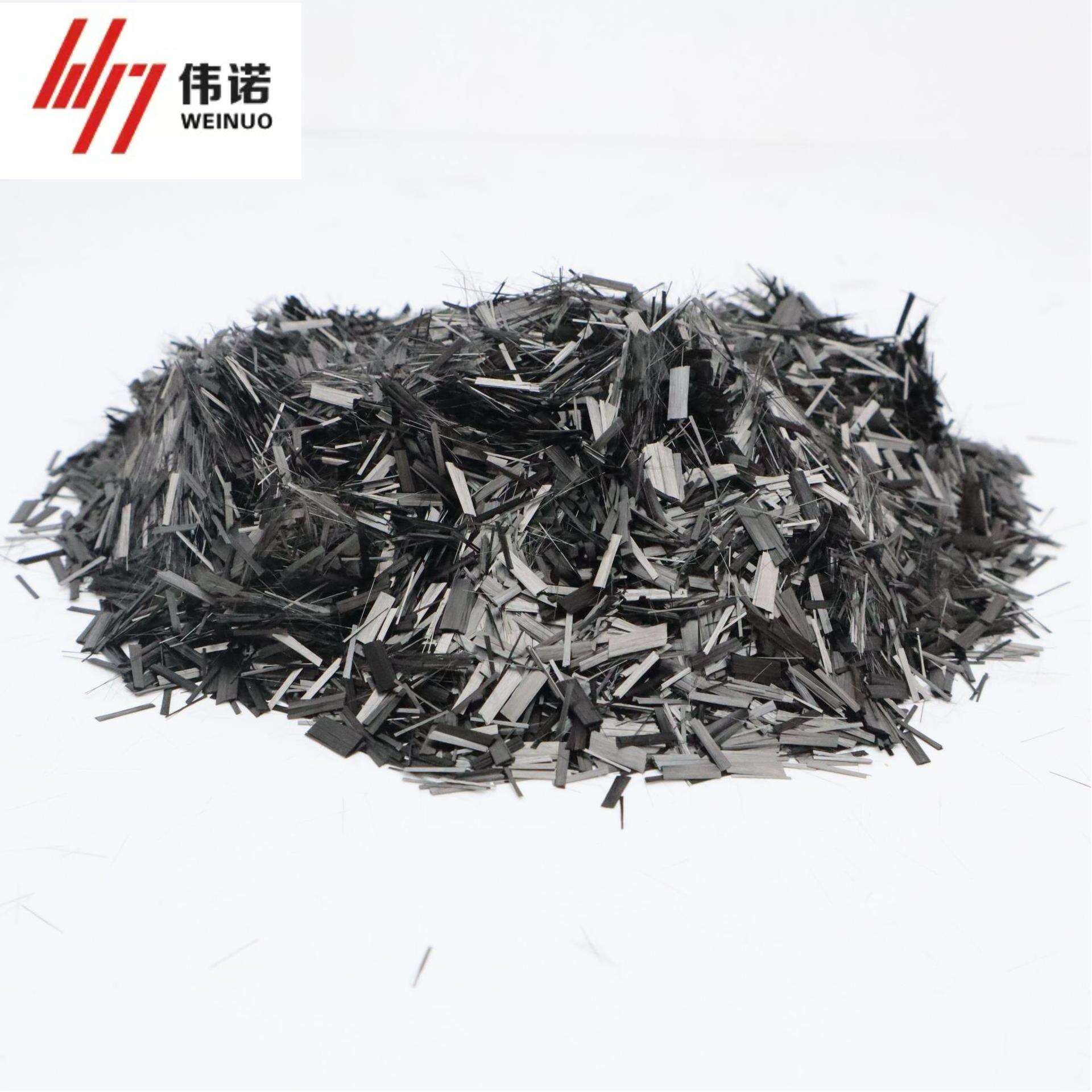

In contrast, chopped carbon fiber systems exhibit more complex strength behaviors due to their discontinuous nature. While individual fiber segments retain their inherent strength properties, the overall composite strength depends heavily on fiber length, orientation distribution, and matrix-fiber interfacial bonding. Typical chopped carbon fiber composites achieve tensile strengths ranging from 200-800 MPa, significantly lower than continuous systems but still offering substantial improvements over traditional materials. The random fiber orientation in many chopped systems provides more isotropic strength properties, beneficial for applications requiring multi-directional load resistance.

Stiffness and Modulus Considerations

Elastic modulus performance varies dramatically between continuous and chopped carbon fiber reinforcement systems. Continuous fiber composites can achieve elastic modulus values exceeding 200 GPa when fibers align with primary loading directions. This exceptional stiffness makes continuous systems ideal for applications requiring minimal deflection under load, such as aerospace structures and precision equipment components. The ability to control fiber orientation allows engineers to tailor stiffness properties to match specific performance requirements through strategic layup designs.

Chopped carbon fiber composites typically exhibit lower overall stiffness values, ranging from 20-80 GPa depending on fiber content and processing methods. However, this reduced stiffness often comes with improved impact resistance and damage tolerance compared to continuous systems. The shorter fiber segments can arrest crack propagation more effectively, preventing catastrophic failure modes common in highly oriented continuous fiber structures. This trade-off between ultimate stiffness and toughness represents a critical design consideration for many industrial applications.

Manufacturing Process Integration

Processing Complexity and Automation

Manufacturing processes for chopped carbon fiber systems offer distinct advantages in terms of complexity and automation potential. The discontinuous nature of chopped carbon fiber enables processing through conventional thermoplastic manufacturing techniques, including injection molding, compression molding, and extrusion processes. These established manufacturing methods allow rapid production cycles and excellent dimensional control for complex geometries. Automated handling of chopped fiber materials also presents fewer challenges compared to continuous systems, reducing labor requirements and improving production consistency.

Continuous carbon fiber processing typically requires specialized equipment and handling procedures to maintain fiber integrity throughout manufacturing. Hand layup, automated tape laying, and resin transfer molding represent common continuous fiber processing methods, each requiring significant technical expertise and quality control measures. While these processes can achieve superior mechanical properties, they often involve longer cycle times and higher manufacturing costs. The complexity of continuous fiber processing also limits design flexibility for certain geometric configurations, particularly those involving sharp corners or complex three-dimensional shapes.

Quality Control and Consistency

Quality control approaches differ significantly between chopped and continuous carbon fiber manufacturing systems. Chopped carbon fiber processing benefits from more uniform material distribution and reduced sensitivity to handling variations during production. The random fiber orientation inherent in many chopped systems helps mask minor processing inconsistencies that might significantly impact continuous fiber performance. Statistical process control methods prove highly effective for monitoring chopped fiber composite quality, enabling consistent production outcomes across large manufacturing volumes.

Continuous fiber systems demand more rigorous quality control protocols to ensure proper fiber alignment, resin infiltration, and void content management. Even minor deviations in fiber orientation or resin distribution can dramatically affect final component performance, requiring sophisticated monitoring and control systems throughout production. Non-destructive testing methods become critical for validating continuous fiber composite integrity, adding complexity and cost to the manufacturing process. However, this enhanced quality control enables achievement of design properties that justify the additional investment for high-performance applications.

Cost-Performance Analysis

Material Cost Structures

The economic considerations surrounding chopped carbon fiber versus continuous fiber selection extend beyond simple material costs to encompass entire product lifecycle expenses. Chopped carbon fiber materials typically cost 30-50% less than equivalent continuous fiber systems, primarily due to reduced processing requirements and material waste during production. The ability to utilize recycled carbon fiber content in chopped systems further reduces material costs while supporting sustainability initiatives. Lower material costs make chopped carbon fiber attractive for high-volume applications where performance requirements allow some trade-offs in ultimate strength properties.

Continuous carbon fiber materials command premium pricing due to their superior performance characteristics and more complex manufacturing requirements. However, the enhanced strength-to-weight ratios achievable with continuous systems can justify higher material costs through reduced material usage in final components. Weight savings in transportation applications, for example, often provide operational cost benefits that offset initial material premiums over product lifespans. Total cost of ownership calculations must therefore consider performance benefits alongside initial material and processing expenses when evaluating continuous fiber systems.

Manufacturing Economics

Processing costs represent another critical factor in the economic comparison between chopped and continuous carbon fiber systems. Chopped carbon fiber manufacturing leverages existing thermoplastic processing equipment, minimizing capital investment requirements for companies transitioning from traditional materials. High production rates achievable through injection molding and similar processes enable favorable unit economics for volume production scenarios. Reduced labor requirements and simplified quality control procedures further contribute to lower overall manufacturing costs for chopped fiber components.

Continuous fiber processing often requires specialized equipment investments and extended production cycles that increase per-unit manufacturing costs. However, the superior performance characteristics achievable may enable premium pricing strategies that offset higher production expenses. Applications requiring maximum performance properties, such as aerospace components or racing applications, can support the additional costs associated with continuous fiber manufacturing. Market positioning and customer value perceptions play crucial roles in determining whether continuous fiber economics prove viable for specific applications.

Application-Specific Performance Trade-offs

Aerospace and Defense Applications

Aerospace applications present unique requirements that influence the selection between chopped carbon fiber and continuous fiber systems. Primary structural components in aircraft typically demand the maximum strength-to-weight ratios achievable through continuous carbon fiber reinforcement. Critical load-bearing elements such as wing spars, fuselage frames, and control surfaces benefit from the directional strength properties and predictable failure modes of continuous fiber systems. Certification requirements in aerospace applications also favor continuous fiber systems due to their well-established design databases and proven performance histories.

Secondary aerospace components may successfully utilize chopped carbon fiber systems where weight savings remain important but ultimate strength requirements allow more flexibility. Interior components, cable management systems, and non-critical brackets represent potential applications for chopped carbon fiber in aerospace environments. The improved impact resistance of chopped systems can actually prove advantageous for components subject to handling damage or debris impact during service. Cost considerations also make chopped carbon fiber attractive for components where performance requirements permit trade-offs in ultimate properties.

Automotive Industry Requirements

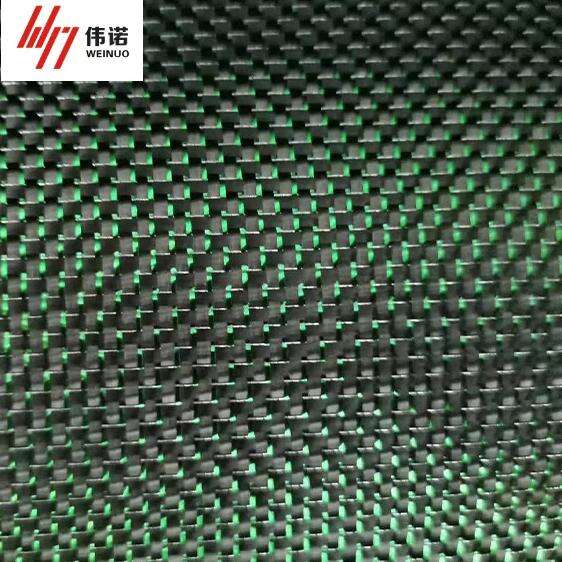

Automotive applications demonstrate the versatility of both chopped carbon fiber and continuous fiber systems across different component categories. High-performance automotive applications, particularly in motorsports and luxury vehicles, frequently utilize continuous carbon fiber for body panels, chassis components, and aerodynamic elements where maximum stiffness and strength prove critical. The aesthetic appeal of visible continuous fiber weave patterns also supports premium branding strategies in automotive markets. However, the high costs associated with continuous fiber processing limit adoption in mass-market vehicle applications.

Mass-market automotive components increasingly incorporate chopped carbon fiber systems to achieve weight reduction goals while maintaining cost competitiveness. Under-hood components, structural reinforcements, and interior elements represent growing applications for chopped fiber materials in automotive manufacturing. The ability to process chopped carbon fiber through existing thermoplastic manufacturing infrastructure enables automotive suppliers to adopt these materials without major capital investments. Crash energy absorption characteristics of chopped systems may also prove advantageous in certain automotive safety applications.

Future Development Trends

Material Technology Advancement

Ongoing research and development efforts continue advancing both chopped carbon fiber and continuous fiber technologies to address current performance limitations. Improved sizing and surface treatments for chopped carbon fiber aim to enhance matrix-fiber interfacial bonding, potentially increasing composite strength properties while maintaining processing advantages. Novel fiber length optimization strategies also seek to balance strength performance with processing characteristics, enabling chopped systems to achieve higher performance levels previously exclusive to continuous fiber systems.

Continuous fiber technology development focuses on reducing manufacturing complexity and costs while maintaining superior performance characteristics. Automated fiber placement systems and advanced resin systems promise to streamline continuous fiber processing for broader industrial adoption. Hybrid reinforcement concepts that combine continuous and chopped carbon fiber elements within single components also represent promising development directions for optimizing performance and cost characteristics. These technological advances may blur traditional distinctions between chopped and continuous fiber performance capabilities over time.

Sustainability and Recycling Considerations

Environmental sustainability concerns increasingly influence material selection decisions between chopped carbon fiber and continuous fiber systems. Chopped carbon fiber manufacturing readily accommodates recycled fiber content from end-of-life composite components, supporting circular economy initiatives within the composites industry. The shorter fiber lengths in chopped systems also prove more compatible with mechanical recycling processes that preserve some fiber properties for reuse applications. This recyclability advantage positions chopped carbon fiber favorably for applications where sustainability metrics influence procurement decisions.

Continuous fiber recycling presents greater technical challenges due to the need to preserve fiber length and orientation characteristics for optimal performance recovery. However, recent advances in chemical recycling processes show promise for recovering high-quality continuous fibers from composite waste streams. Life cycle assessment methodologies increasingly factor into material selection processes, potentially favoring systems that demonstrate superior environmental performance throughout product lifecycles. Sustainability considerations may therefore drive continued innovation in both chopped and continuous carbon fiber recycling technologies.

FAQ

What are the main strength differences between chopped carbon fiber and continuous fiber composites

Continuous carbon fiber composites typically achieve tensile strengths exceeding 3,500 MPa due to uninterrupted load paths, while chopped carbon fiber systems range from 200-800 MPa. The continuous fibers provide superior directional strength but chopped systems offer more isotropic properties and better impact resistance. The choice depends on specific application requirements and acceptable performance trade-offs.

How do manufacturing costs compare between chopped and continuous carbon fiber processing

Chopped carbon fiber processing costs 30-50% less than continuous fiber systems due to compatibility with existing thermoplastic equipment and simpler handling requirements. Continuous fiber manufacturing requires specialized equipment and longer cycle times but can justify higher costs through superior performance in demanding applications. Total cost analysis must consider both material and processing expenses along with performance benefits.

Which fiber type works better for high-volume production applications

Chopped carbon fiber systems excel in high-volume production due to compatibility with automated thermoplastic processing methods like injection molding. These processes enable rapid cycle times and consistent quality control for large production runs. Continuous fiber processing typically involves more complex, time-intensive methods better suited for lower-volume, high-performance applications where superior properties justify longer production cycles.

Can chopped carbon fiber achieve similar performance to continuous fiber in any applications

While chopped carbon fiber cannot match the ultimate strength properties of continuous systems, it can provide adequate performance for many applications while offering advantages in impact resistance, processing flexibility, and cost-effectiveness. Applications requiring multi-directional loading, complex geometries, or enhanced toughness may actually benefit from chopped fiber characteristics over continuous systems despite lower absolute strength values.

Table of Contents

- Structural Performance Characteristics

- Manufacturing Process Integration

- Cost-Performance Analysis

- Application-Specific Performance Trade-offs

- Future Development Trends

-

FAQ

- What are the main strength differences between chopped carbon fiber and continuous fiber composites

- How do manufacturing costs compare between chopped and continuous carbon fiber processing

- Which fiber type works better for high-volume production applications

- Can chopped carbon fiber achieve similar performance to continuous fiber in any applications